- Provisionally fit the piston into the cylinder, without any base gasket.

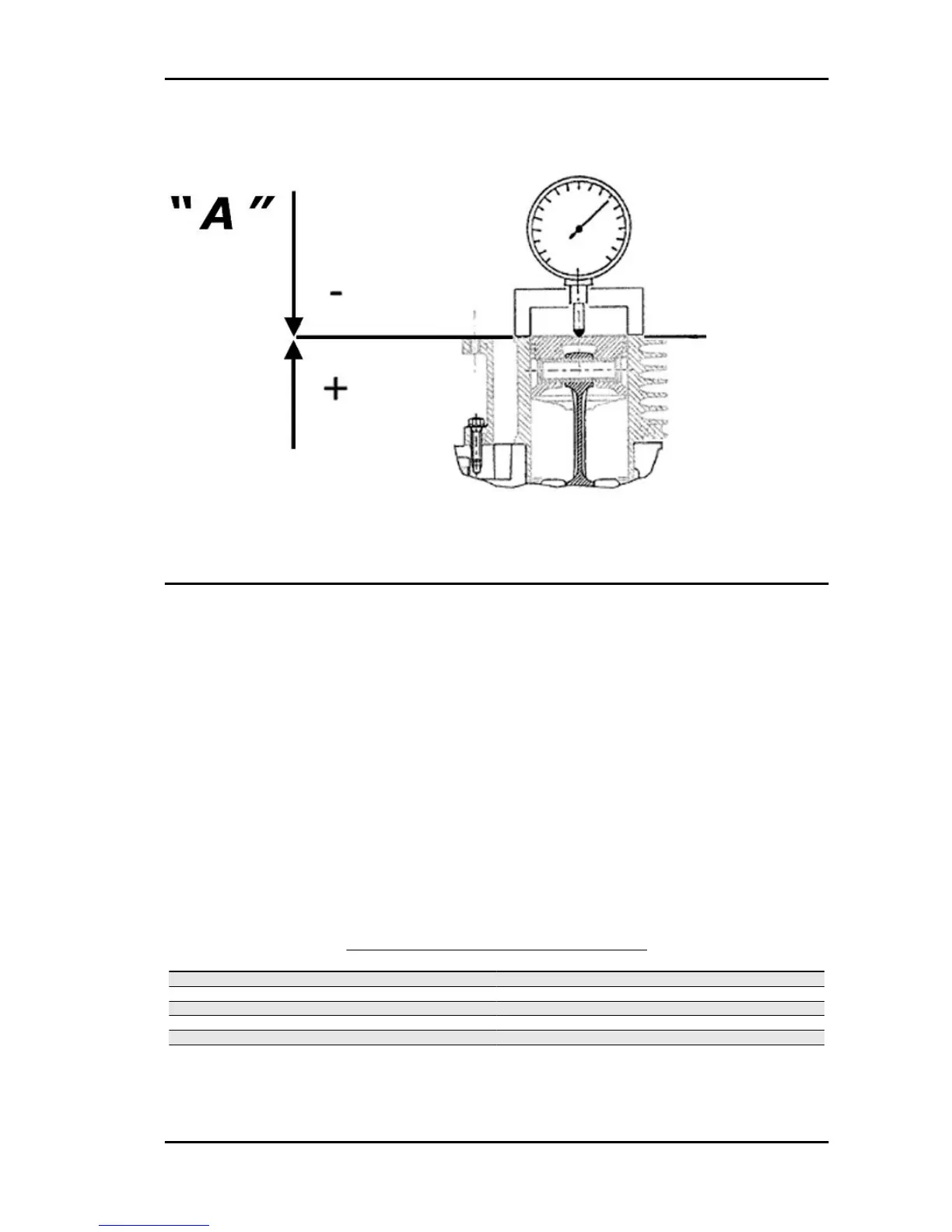

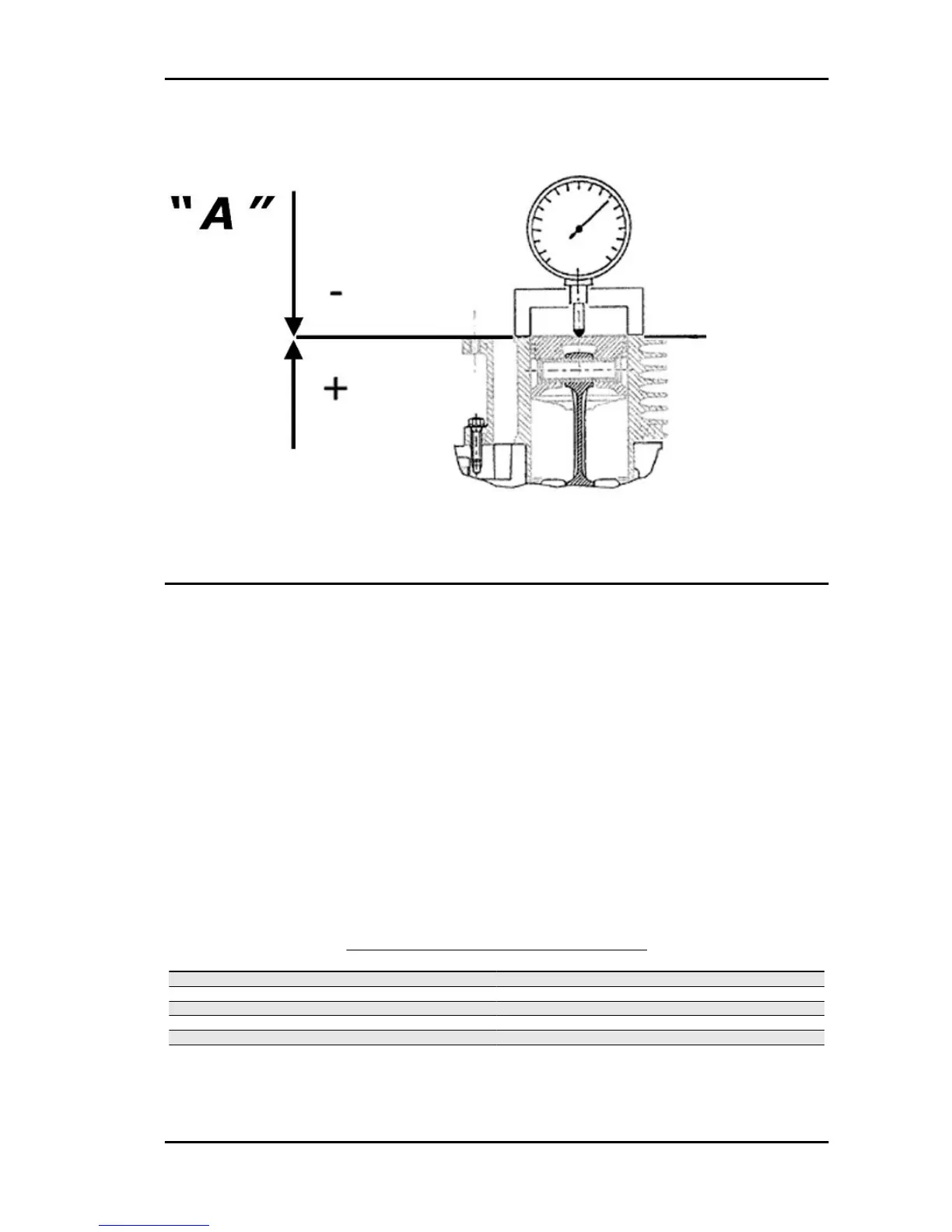

- Fit a dial gauge on the specific tool, then rest both on a stop surface.

- Zero set the dial gauge on the stop surface. Keeping the zero position, assemble the tool on the cylinder

and lock it with 2 nuts as shown in the figure.

- Rotate the crankshaft until TDC (the inverted point of the dial gauge rotation)

- Measure piston protrusion compared with the head plane and determine the gasket thickness to be

used according to the table below. By correctly identifying the cylinder base gasket thickness, an ade-

quate compression ratio is maintained.

- Remove the specific tool and the cylinder.

Characteristic

Standard compression ratio

C.R. 11.5 ÷ 12 ÷ 1

CYLINDER BASE GASKET THICKNESS

Specification

Desc./Quantity

Cylinder height 56.45 ± 0.05

Head gasket thickness (fibre) 0.95 ± 0.06

Measure detected 0.9 ± 0.05

Base gasket thickness 0.4

Measure detected 1 ± 0.05

Base gasket thickness 0.5

MSS Fly 50 4T Engine

ENG - 91

Loading...

Loading...