MAINTENANCE

6-48 / Wheels and Tires

© 2020 Pierce Manufacturing Inc. All Rights Reserved.

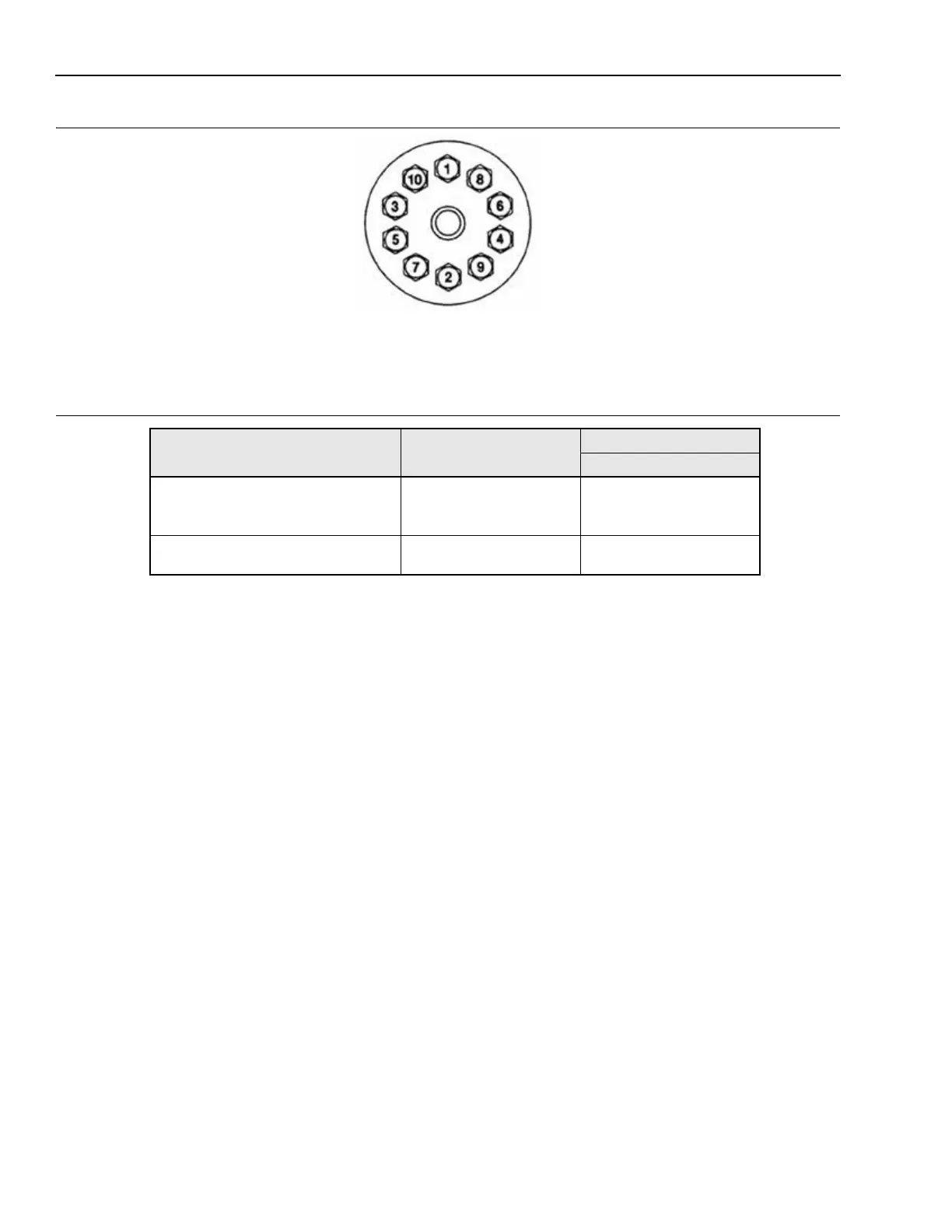

Figure 6-15: Wheel Nut Tightening Sequences

1603

Table 6-10: Wheel Nut Torque Chart

4. Snug up flange nuts alternately in the sequence shown. Rotate wheel assembly one-half turn to allow the wheel

to seat. DO NOT tighten them fully until all have been seated. This procedure will permit the uniform seating of

nuts and ensure the even, face-to-face contact of wheels and hub.

5. Tighten flange nuts fully, using the same alternating sequence. In each case, be sure to tighten wheel nuts only

to the torque level recommended in the table and to maintain them at that level through planned, periodic

checks.

6. Check torque on wheel nuts after the first 25 to 50 miles of service.

Mounting Thread Size

Torque

Ft-Lbs (Lubricated)

10 Hole, 285.75 mm – Hub Piloted

with cab brakes or Meritor EX225

disc brakes

M22 x 1.5 450–500

10 Hole, 285.75 mm – Hub Piloted

with Meritor ADB 1560 disc brakes

M22 x 1.5 390–450

HUB PILOT

FRONT AND REAR DUALS

Loading...

Loading...