© 2020 Pierce Manufacturing Inc. All Rights Reserved. Axles, Tires, and Brakes / 3-5

BEFORE PLACING VEHICLE IN SERVICE

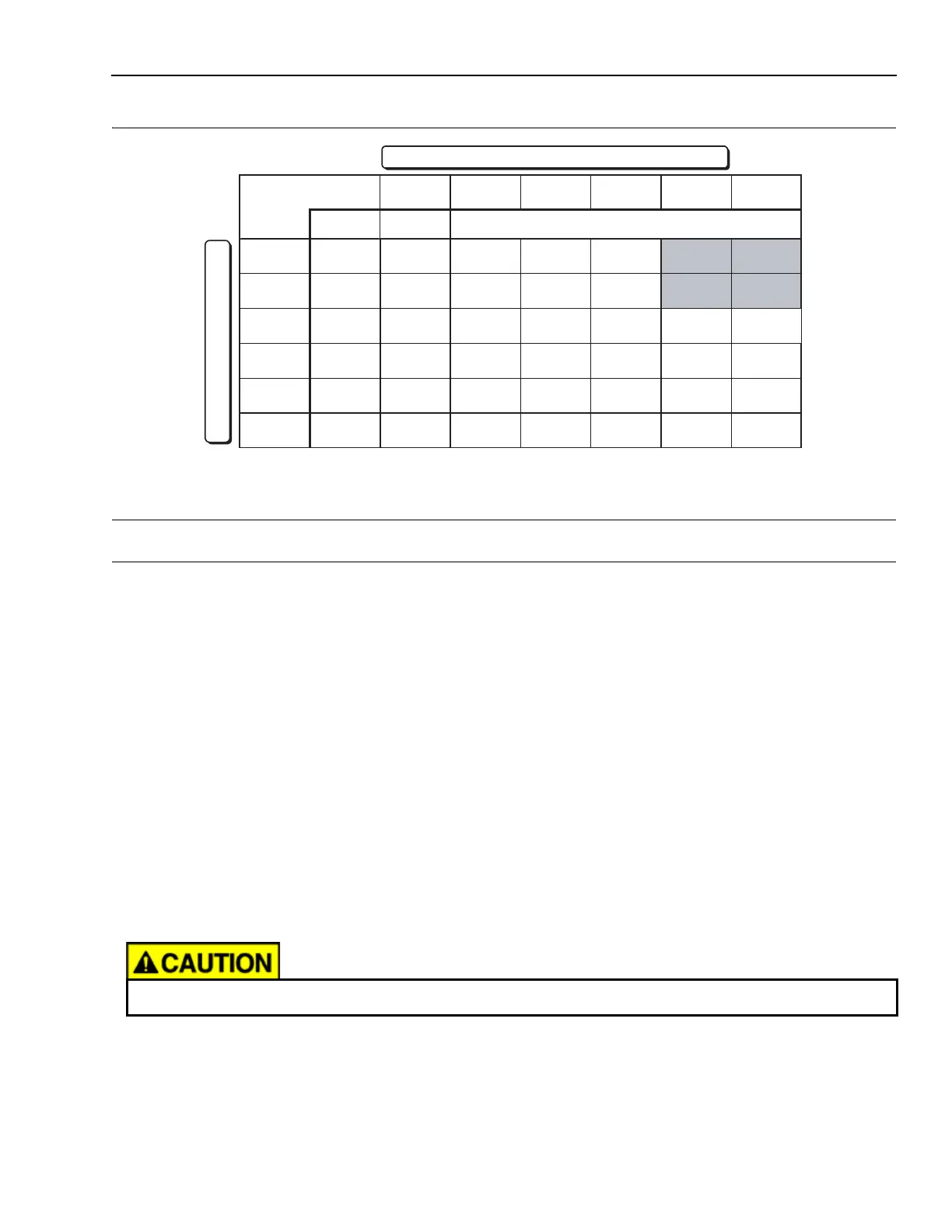

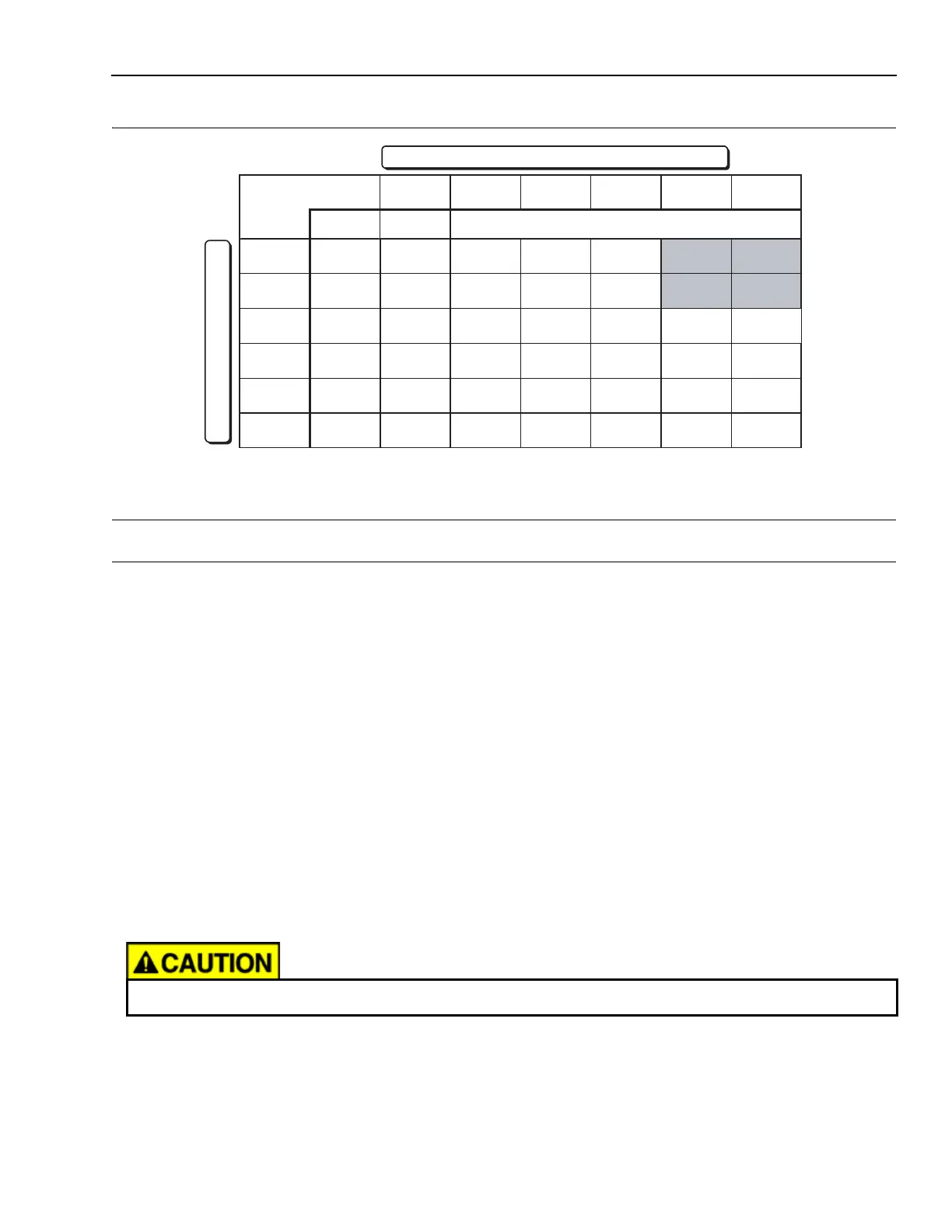

Figure 3-4: Brake Power Chart (Disc Brakes Front, ALL STEER

®

Cam Brakes Rear)

POM0042

3-4. Brake Burnishing

3-4.1 General Information

IMPORTANT: Brake noise is an inevitable characteristic of heavy-duty truck brakes with aggressive

friction materials. Total elimination of all brake noise in heavy truck brakes cannot be

expected.

Brakes shoes and pads are most effective after they have been worn-in sufficiently so that the surface of the friction

material mates consistently with the drum or rotor surface. The process of wearing-in the friction material is termed

“burnishing.” Braking performance and grade holding ability will improve once the brakes are burnished. The

following burnish procedure is recommended by the axle and brake manufacturer to optimize brake performance

and minimize the possibility of developing brake squeal or vibration.

Pierce recommends a burnishing procedure be done after a new truck has been delivered and has been loaded to

its in service weight. This same practice should also be done after new brakes, disc brake pads or drum brake shoes

have been installed. This will ensure that they are broken in properly and will give proper performance during

stopping and grade holding.

3-4.2 Procedure

Before starting the brake burnish procedure, make sure the brake chamber slack adjuster strokes, both free and

applied, are within the brake supplier specifications. For brakes without slack adjusters, ensure that the caliper

running clearance is correct. Refer to the axle manufacturer’s maintenance manual (included in the Pierce Service

Manual) for maintenance schedules, lubrication recommendations, and inspection procedures.

Make sure the driving route is in a safe, low traffic area.

In-Service Axle

Weights (Lb.)

11,000-14,600 14,601-16,540 16,541-18,000 18,001-18,999 19,000-20,000 20,001-21,500

Axle Model FG941

17,000-21,500 AWS21.5

Front:24 x 5-1/2

Rear:30 x 5-1/2

Front:24 x 5-1/2

Rear:30 x 5-1/2

Front:24 x 5-1/2

Rear:30 x 5-1/2

Front:24 x 5-1/2

Rear:30 x 5-1/2

21,501-24,000 AWS24

Front:24 x 5-1/2

Rear:30 x 6

Front:24 x 5-1/2

Rear:30 x 6

Front:24 x 5-1/2

Rear:30 x 6

Front:24 x 5-1/2

Rear:30 x 6

24,001-26,000 AWS26

Front:24 x 5-1/2

Rear:30 x 6

Front:24 x 5-1/2

Rear:30 x 6

Front:24 x 5-1/2

Rear:30 x 6

Front:24 x 5-1/2

Rear:30 x 6

Front:24 x 5-1/2

Rear:30 x 6

Front:30 x 5-1/2

Rear:30 x 6

34,000-42,000 AWS42

Front:24 x 5-1/2

Rear:30 x 5-1/2

Front:24 x 5-1/2

Rear:30 x 5-1/2

Front:24 x 5-1/2

Rear:30 x 5-1/2

Front:24 x 5-1/2

Rear:30 x 5-1/2

Front:24 x 5-1/2

Rear:30 x 5-1/2

Front:30 x 5-1/2

Rear:30 x 5-1/2

42,001-48,000 AWS48

Front:24 x 5-1/2

Rear:30 x 6

Front:24 x 5-1/2

Rear:30 x 6

Front:24 x 5-1/2

Rear:30 x 6

Front:24 x 5-1/2

Rear:30 x 6

Front:24 x 5-1/2

Rear:30 x 6

Front:30 x 5-1/2

Rear:30 x 6

48,001-52,000 AWS52

Front:24 x 5-1/2

Rear:30 x 6

Front:24 x 5-1/2

Rear:30 x 6

Front:24 x 5-1/2

Rear:30 x 6

Front:24 x 5-1/2

Rear:30 x 6

Front:24 x 5-1/2

Rear:30 x 6

Front:30 x 5-1/2

Rear:30 x 6

FL941/FL943

FRONT

RA

E

R

Loading...

Loading...