© 2020 Pierce Manufacturing Inc. All Rights Reserved. Engine Exhaust After Treatment Systems / 5-21

OPERATION

Engine Exhaust After Treatment Systems

5-11. Introduction

NOTE: Applies to all U.S. Domestic vehicles manufactured after 2007 and some export vehicles.

Your Pierce apparatus is equipped with a specialized exhaust equipment designed to meet tiered EPA regulations,

based on both calendar year and vehicle usage (i.e. on-road or off-road), to reduce soot (partially burned fuel

particles), ash (partially burned oil particles), and nitrogen oxide (NOx) emissions.

5-11.1 Emissions Equipment and Functions

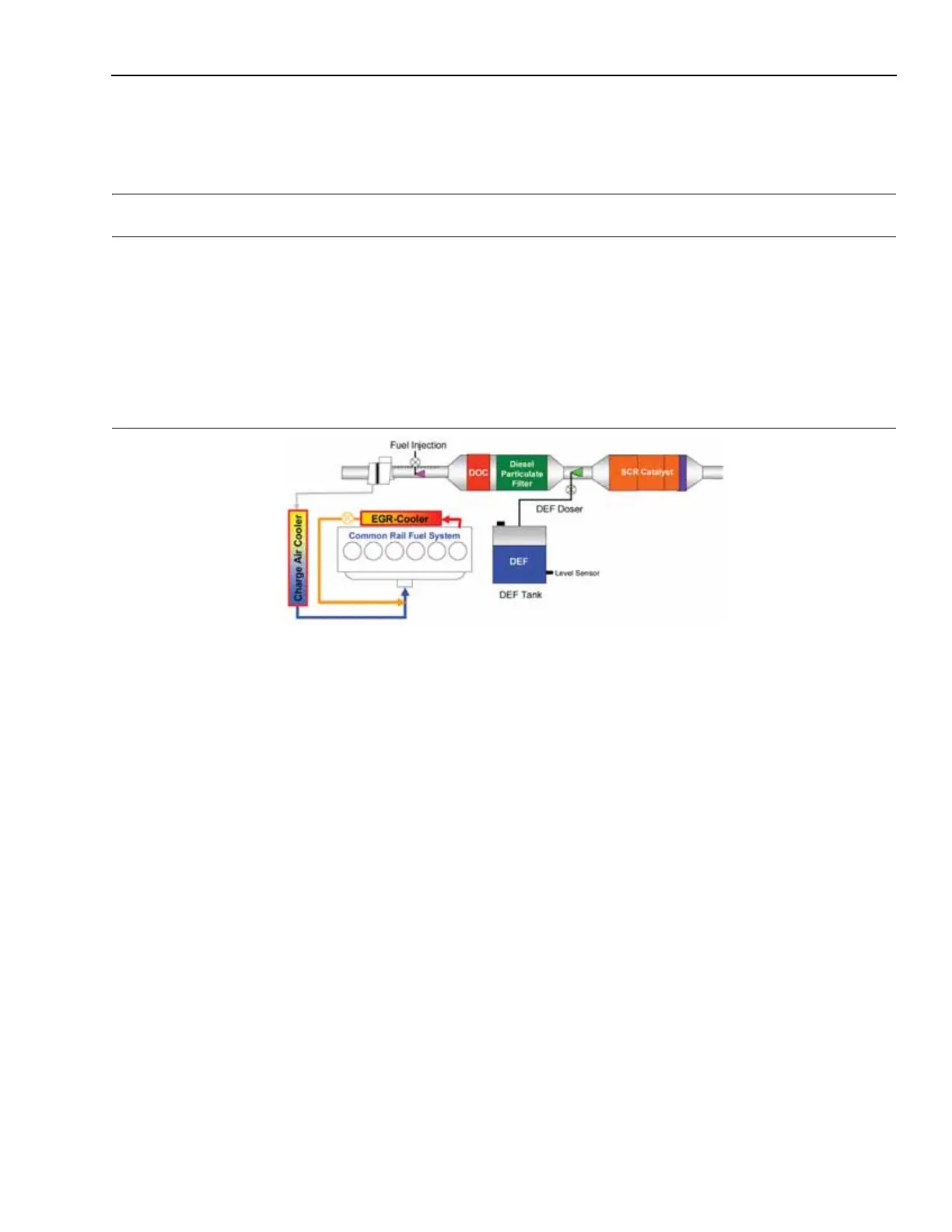

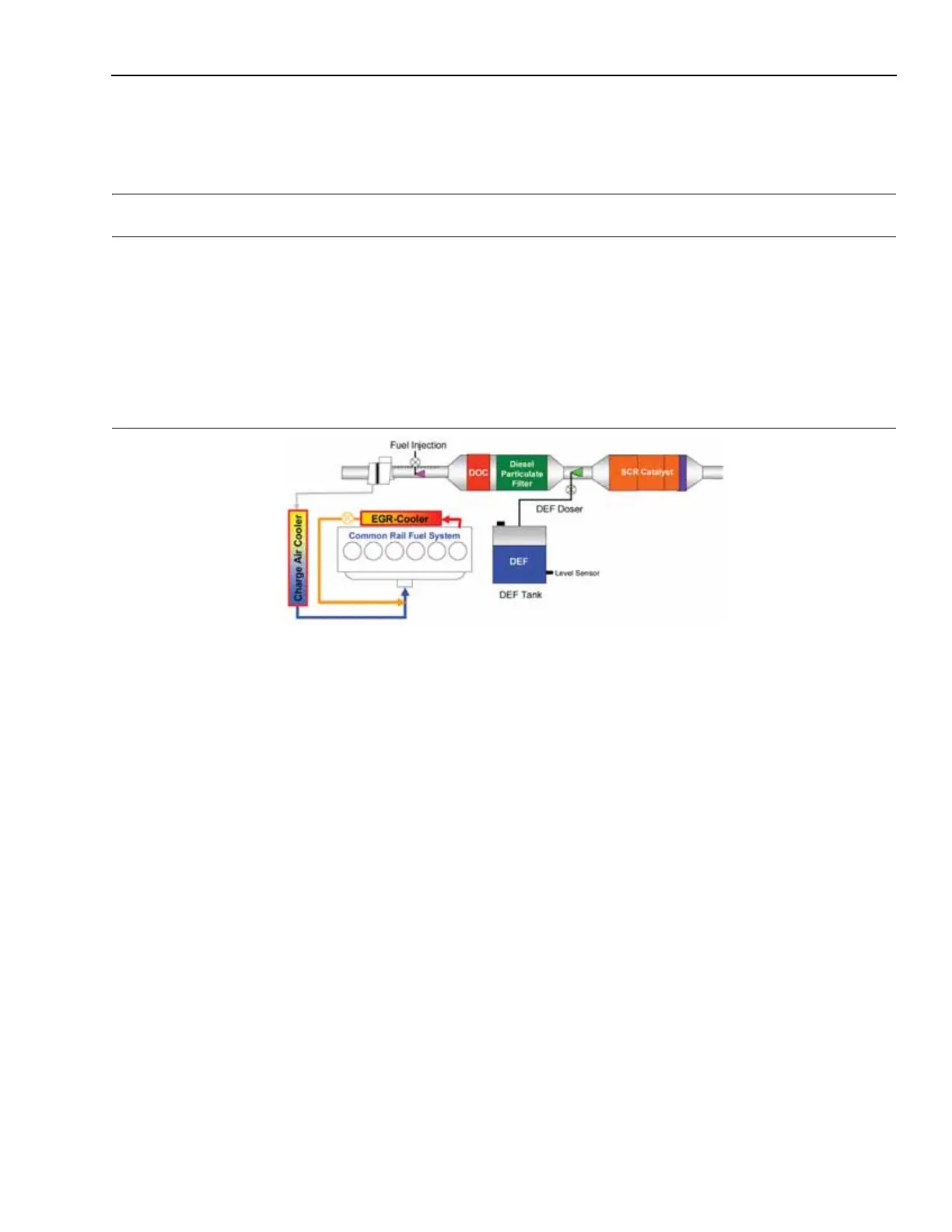

Figure 5-1: Typical After Treatment System Components (2010 and Later EPA Engines)

A0062

The major after-treatment devices used with the engine in your Pierce® fire apparatus may include:

• After Treatment Device (ATD), a special exhaust canister which has replaced the typical muffler. This canister

contains a Diesel Oxidation Catalyst (DOC) and a Diesel Particulate Filter (DPF). The DPF will trap particulate

matter or soot and ash while the engine is running. Soot accumulation in the DPF requires periodic self-cleaning

through a process called regeneration.

— Regeneration may occur naturally when the exhaust is hot enough to burn the soot off.

— Regeneration may require intervention, either by the engine ECU or operator intervention, by injecting a

small amount of fuel into the DOC, which raises exhaust temperatures enough to burn off accumulated soot.

—See “Cummins and Ford Regeneration” on page 5-22 or “Detroit Diesel ATD Regeneration” on page 5-27

depending on your engine.

• Selective Catalyst Reduction (SCR) device. The SCR is a catalytic converter that uses vaporized diesel exhaust

fluid (DEF), fed by a tank., to reduce nitrogen oxide (NOx) emissions created during the combustion process.

• Diesel Exhaust Fluid (DEF). Also known as DEF, urea, or Ad-Blue, a solution of 32.5% urea and deionized water,

which breaks down into ammonia NH

3

) during a chemical reaction in a decomposition reactor through a process

known as hydrolysis. The NOx and ammonia (NH

3

) pass into the SCR element where a catalytic reaction takes

place, converting the NOx into harmless nitrogen gas (N

2

) and water vapor (H

2

O).

• Related indicator lamps on the driver display to alert the operator of the after-treatment equipment status. Light

functionality is explained in “After Treatment Device Indicator Lights - Cummins and Ford Engines” on

page 5-22. and “After Treatment Device Indicator Lights - Detroit Diesel” on page 5-27.

• 2013 EPA and later emissions requirements include engines receiving an upgraded engine ECU with fully-

integrated On-Board Diagnostics (OBD). The drive engine indicator panel also includes an additional

Malfunction Indicator Lamp (MIL).

Loading...

Loading...