Overview

System Description Service Robotics Modules

1004870-EN-05

| 8

2 Overview

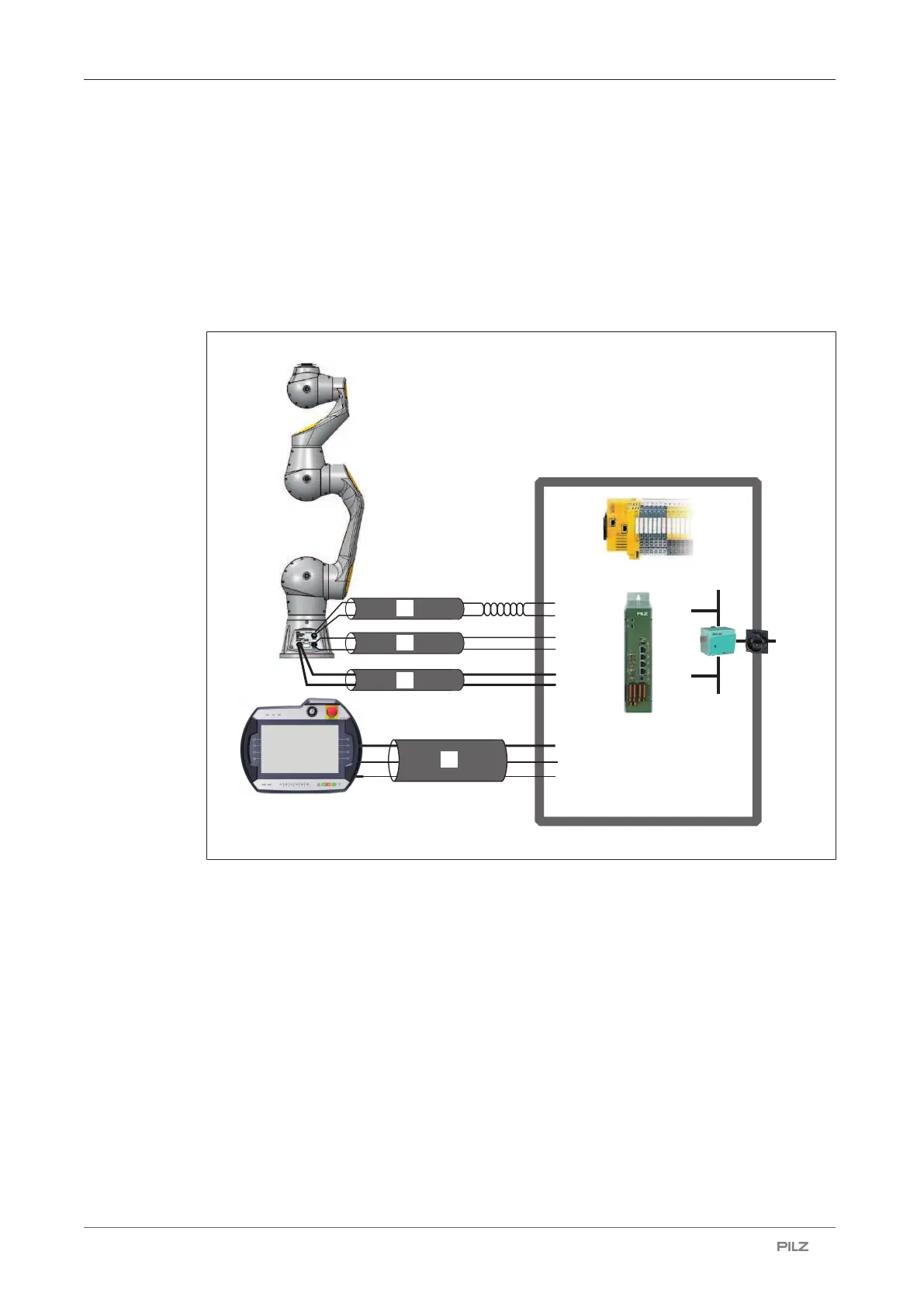

2.1 Overview of industrial robots with service robotics modules

from Pilz

Using the robot arm PRBT 6 together with the robot control module PRCM1 (control cab-

inet) and the teach pendant PRTM1, an industrial robot can be built that corresponds to the

harmonised standard ENISO10218-1.

[1]

[2]

[3]

Safety control system

Motion controller

Ethernet

- Enable signal for operating mode selection

- Emergency stop signal

- Enabling signal

STO

CANopen

24 VDC

24 VDC

Robot arm

End-effector

X1 (Power)

[4]

[5]

[7]

X3 (AUX)

[6]

X2 (Signals)

230 VAC

Fig.: Industrial robots with service robotics modules from Pilz

Legend

[1] Robot arm PRBT 6 with

} Inputs for triggering STO and SBC via two separate shutdown paths

} Flange for attachment of a suitable end-effector

} Communication interface (CANopen) for controlling the axes and the end-effector

[2] Teach pendant PRTM1 with

} Software from Pilz for programming, commissioning and diagnostics of the Pilz in-

dustrial robots

} Key switch to release the operating mode selection

} Emergency stop pushbutton

} Enabling device (3-stage) for the manual operating modes

Loading...

Loading...