PN-0908073 Rev. 11 51-92

PS 164-2

THE ART OF WELDING

5. 3. 9. 3. Deleting a program from the memo card

• Check that the key switch SY 26 is in the position

" Modifi cation authorised ".

• Choose any existing program in the source mem-

ory.

• Insert the memo card.

• Press the transfer button (symbol ).

• Press the button " trash " (symbol

), the name

of the fi rst program stored on the memo card is

shown on the display.

The keys SY 17 and SY 19 are used to scroll up and

down the program you wish to delete.

• Validate the transfer by pressing

. The corre-

sponding indicator will illuminate.

You can cancel the suppression of a programme by

pressing again the button " trash ".

5. 3. 10. Printing a program

To print a program from a memo card, the procedure

is as follows:

• With the switch BT 4 on the remote control

pendant, choose the number of the program to

print.

• Press the print button (symbol ).

• Validate. The printing indicator is illuminated.

• After the printing is fi nished, this indicator will ex-

tinguish.

5. 3. 11. Functioning modes

Modifi cations of the values of weld parameters can

be done in two different modes, one during devlop-

ment of a weld procedure and the second in produc-

tion.

◊ Modifying the parameters before starting a

program

To select this mode, turn the key operated switch

SY 26 to the "Modifi cation authorised" position (sym-

bol

). The key can be removed afterwards.

In this mode you can increase (+) or decrease (-)

during the weld cycle the values of the I22, V32 (for

no-pulsed speed rotation), V33 (for pulsed speed ro-

tation) or V42 parameters with the "Delta" buttons.

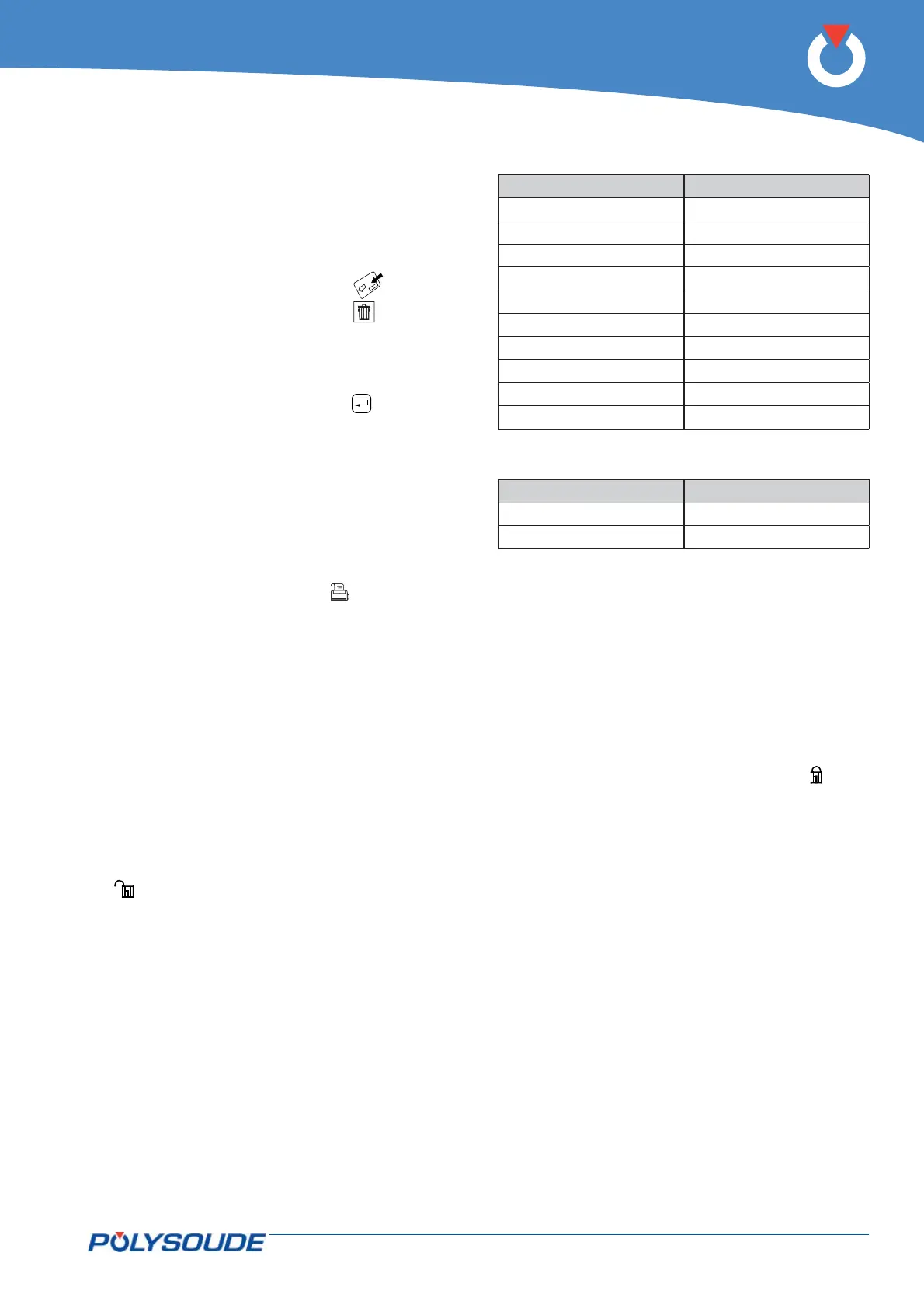

The modifi cation values of the delta buttons cannot

be changed by the user. It depends on the value of

the parameter which is being acted upon. The table

below gives the relationship between the parameter

value and the correction made by each press of the

delta button.

When a delta button is used, the value of the param-

eter concerned is displayed during 5 seconds on the

front face of the PS 164-2.

Wire feeder rotation speed :

Value of parameter Delta

≤ 99 1

100 - 199 2

200 – 299 3

300 – 399 4

400 – 499 5

500 – 599 6

600 – 699 7

700 – 799 8

800 – 899 9

900 – 999 10

Welding current :

Current range 160 A :

Value of I22 or I23 Position

≤99 1

100-160 2

Current range 50 A : Deltas I = 0,1 A

All actions on the delta buttons are taken into ac-

count (within the parameter limits) and stored in the

memory of the relevant sector. After moving from

one sector to another, the corrections made in the

preceding one are carried through to the next. The

modifi cations are not forgotten or lost. The number

of deltas in this mode is not limited.

Modifi cations made during the weld cycle.

To access the production mode, the key operated

switch SY 26 has to be turned to the "Program mod-

ifi cation not authorised" position (symbol

). The

key can be removed afterwards to avoid unauthor-

ised modifi cations being made to the programs.

This mode includes two differences:

• The number of deltas per parameter is limited to

10 (10 increments or 10 decrements)

• The modifi cations are not stored in the memory.

◊ Fault detecting during cycle

During every welding cycle, important parameter

values are monitored periodically at different deli-

cate points. When a fault is detected, an immediate

stop or a stop with downslope is initiated depending

on the seriousness of the fault. The fault is indicated

by a fl ashing light on the remote control pendant.

An error code will also appear on the display of the

PS 164-2. Appendix 7.2 gives the error codes, their

meaning and their consequences. We advise you to

take careful notice as to which error code is shown.

This can make maintenance or repair work easier

and highly effi cient.

Loading...

Loading...