54-92 PN-0908073 Rev. 11

PS 164-2

THE ART OF WELDING

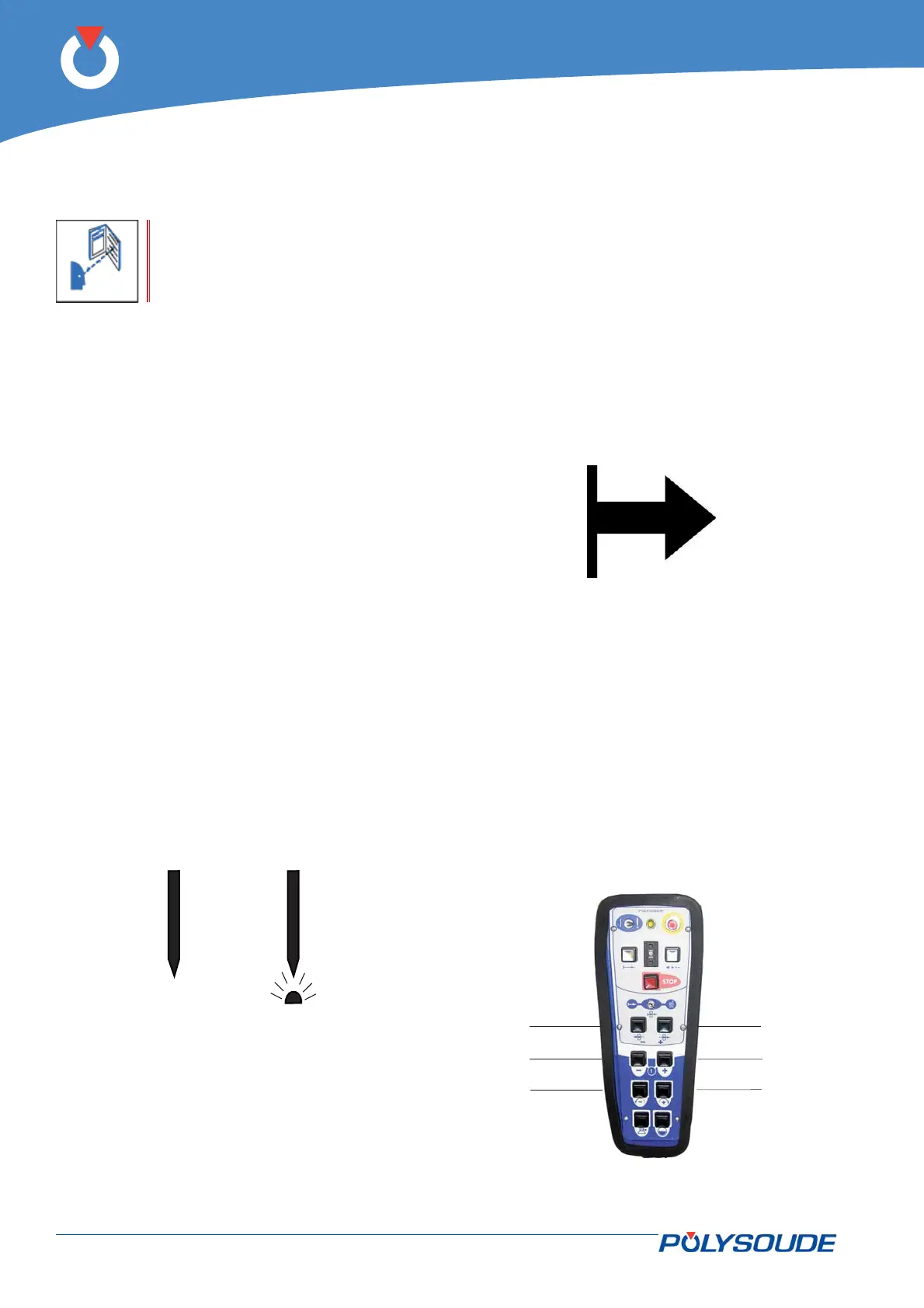

BT 9 BT 8

BT 11 BT 10

BT 14 BT 13

5. 4. Execution of a weld program

5. 4. 1. Safety precautions

Before starting any manipulation

on the equipment please refer to

chapter 1 "Safety precautions".

5. 4. 2. Choosing the program to be executed

The program to be executed is selected with the

switch BT 4 on the remote control pendant. You can

check the name of the program on the display of the

PS 164-2. If only "POLYSOUDE PS 164-2" appears,

you have selected the number of a user program

place where nothing is stored in the memory of the

PS 164-2. If ! 75 ! is displayed on the screen, the

right range of current is not selected.

5. 4. 3. Simulation

After the correct program has been selected, you can

run a simulation without affecting the workpiece to

be welded. In this case, all the functions of the se-

lected program are carried out except those concern-

ing the arc and the coolant circuit.

The gas controls are executed but the fl ow rates are

not considered. So it is possible to check fl ow adjust-

ment or reduce gas consumption during the simula-

tion.

The choice between a simulated or a real weld cycle

is made with the switch BT 1 on the remote control

pendant.

Fig. 5.6 - "Set up / weld" selector switch

5. 4. 4. Weld cycle

5. 4. 4. 1. Starting the weld cycle

The weld cycle is initiated by pressing the button

BT 5 on the remote control pendant. The indicator

BT 3 becomes illuminated when the cycle starts.

If for the selected number a program does not ex-

ist in the memory of the PS 164-2, no cycle will be

started and the indicator will fl ash. The fl ashing can

be turned off by pressing any button on the remote

control pendant.

5. 4. 4. 2. Modifi cation of a weld cycle

Parameter values can be modifi ed during the weld

cycle with the remote control pendant. The values of

the modifi able parameters in each sector are:

• The current or maximum current in the case of

pulsed current (I22).

• The rotation speed (V32) or low rotation speed in

case of pulsed rotation (V33).

• The wire speed or the high wire speed in the case

of pulsed wire (V42).

Fig. 5.7 - "Start cycle" button

Fig. 5.8 - "Delta" buttons for modifi cations of

parameter values

Loading...

Loading...