74-92 PN-0908073 Rev. 11

PS 164-2

THE ART OF WELDING

1248

◊ The source

The power command, generated by the sequencer

card, is an analogical signal 0 to 10 V. At 10 V, it cor-

responds to 160 A, and at 0 V it corresponds to the

minimum current of the source, 4 A, for the 160 A

range; at 10 V it corresponds 50 A, and at 0 V it cor-

responds 4 A, for the 50 A range.

A logic order active at high level (15 V) controls the

running of the source.

The source sends a signal indicating that it is over-

heated. The signal is released by the sequencer card

to stop the weld cycle and display the code of the

detected fault (27).

The high frequency power source is controlled by a

signal emitted from the sequencer card. A relay con-

tact ensures that this action occurs. The other pole of

contact is linked to an alternative voltage of 42 V.

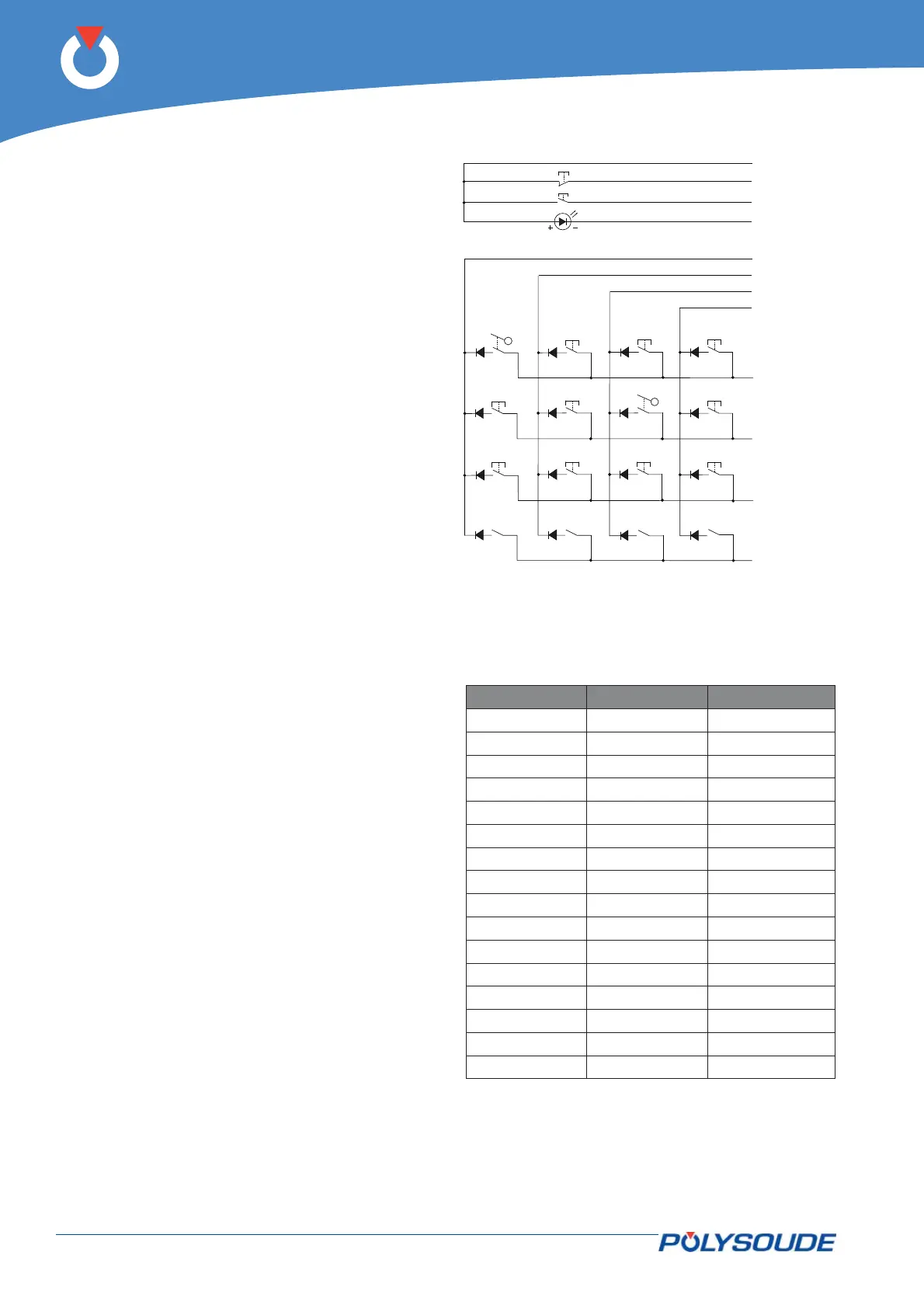

◊ The remote control pendant

The buttons on the control pendant are controlled

by the synoptic card (21700634). Most of the but-

tons are tested by the line and column method: A

high level signal is placed on a line and the columns

are tested. If a column is at a high level, this shows

that the button associated with this line and column

has been pressed. The next line is tested afterwards,

and so on. Only the two safety buttons are directly

linked.

The In cycle indicator is a light emitting diode LED.

Fig. 6.22 - Remote control pendant logic

LINE COLUMN BUTTON

11BT 1

1 2 BT 16

1 3 BT 11

1 4 BT 14

21BT 5

2 2 BT 15

2 3 BT 12

24BT 9

31BT 6

3 2 BT 10

3 3 BT 13

34BT 8

4 1 BT 4 (1)

4 2 BT 4 (2)

4 3 BT 4 (4)

4 4 BT 4 (8)

Emergency stop

Stop

In cycle

Column 1

Column 2

Column 3

Column 4

Line 1

Line 2

Line 3

Line 4

Loading...

Loading...