PN-0908073 Rev. 11 53-92

PS 164-2

THE ART OF WELDING

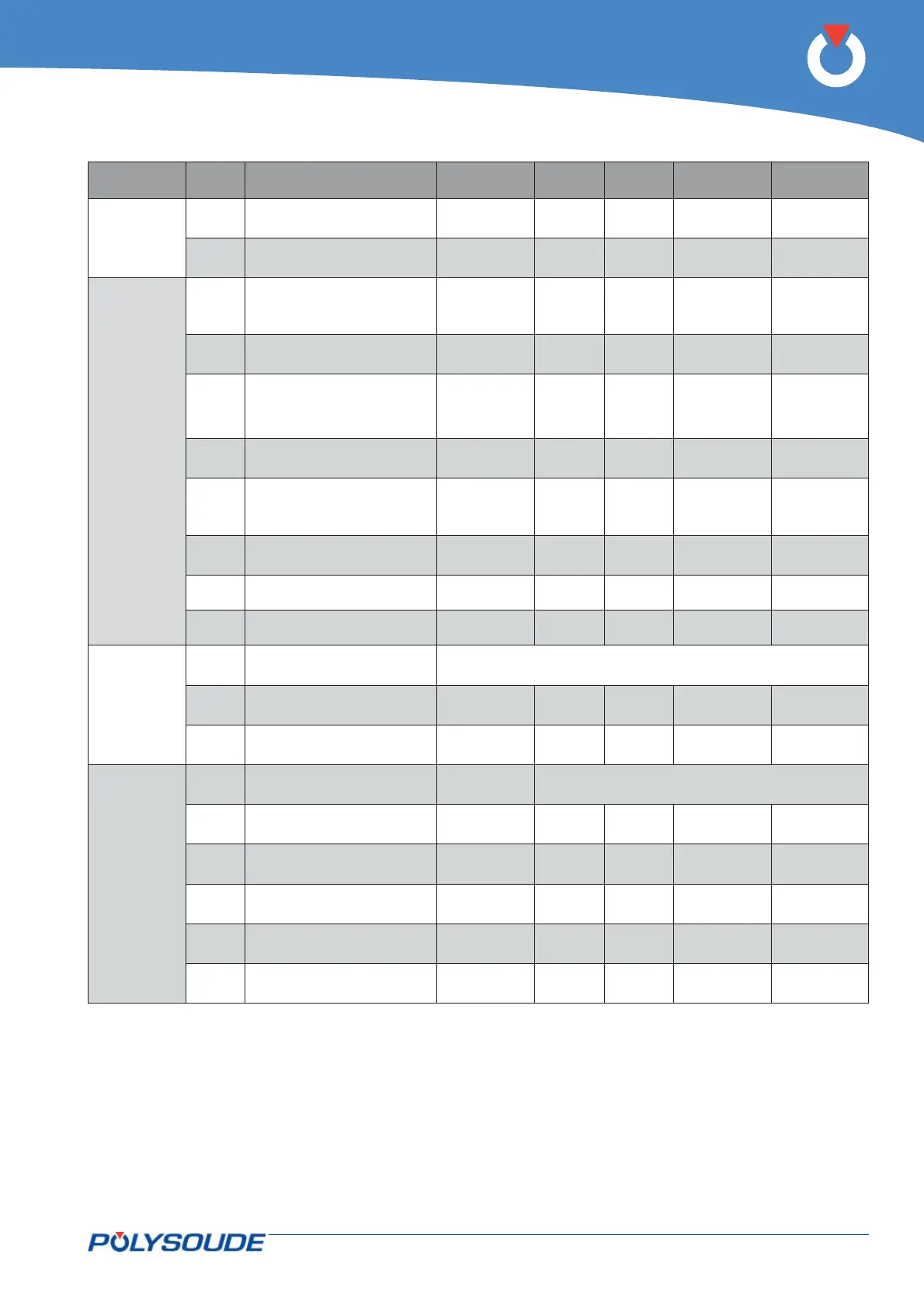

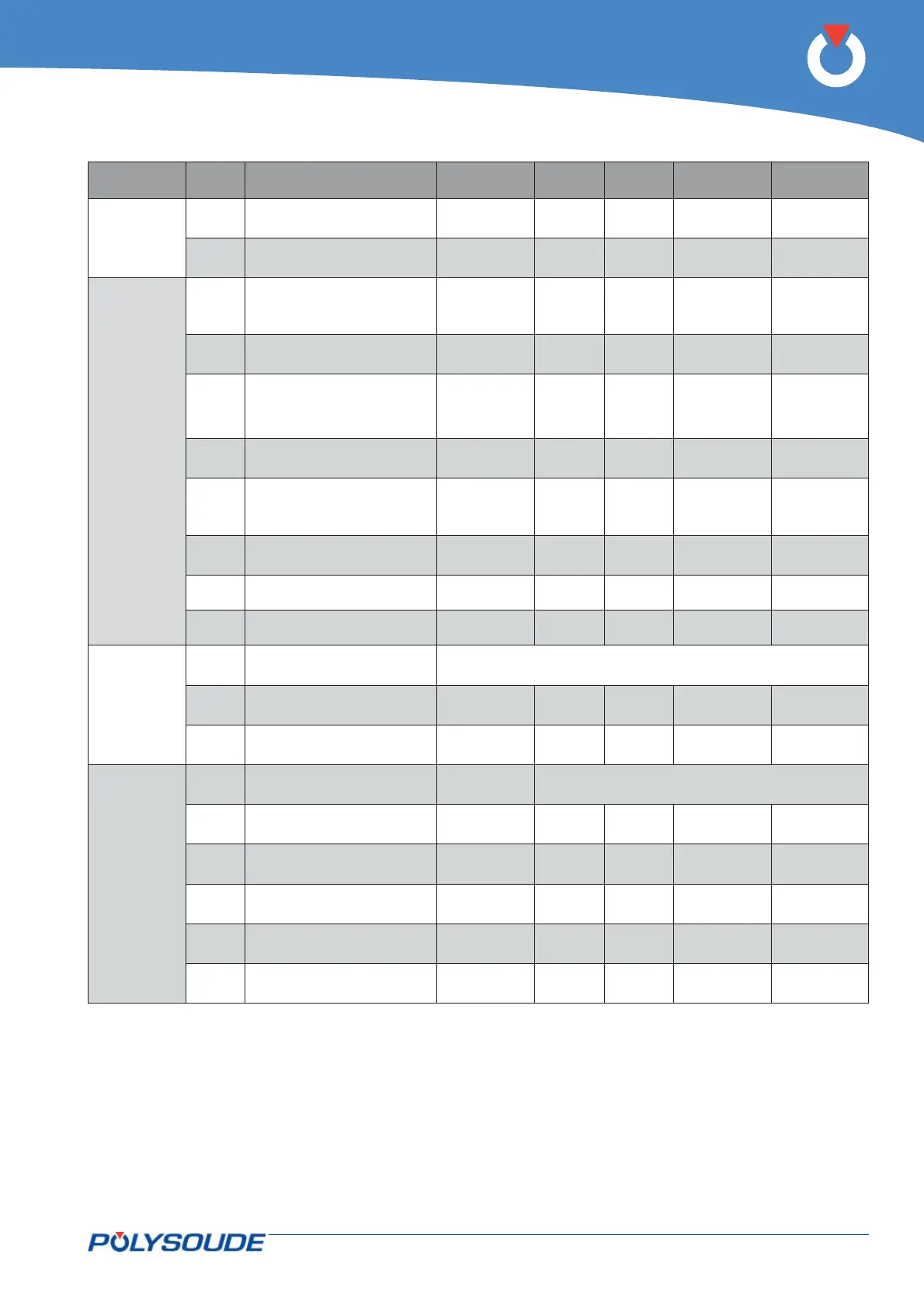

REF DESIGNATION MAX. MIN. UNIT INCREMENT

DEFAULT

VALUE

Gas

T10 Pre-gas time 320 1 s 1 5

T11 Post-gas time 320 1 s 1

10

15*

Current

I21 Prefusion current

160

100

50*

4

4*

A

1

0,1*

90

10*

T21 Prefusion time 30 0,1 S 0,1 3

I22 High current

160

100

50*

4

4*

A

1

0,1

90

10*

T22 High current time 9999 10 Ms 1 100

I23 Low current

160

100

50*

4

4*

A

1

0,1

45

5*

T23 Low current time 9999 10 Ms 1 100

N20 Downslope 9999 1 D 1 365

T25 Downslope time 60 1 S 1 5

Rotation

R30 Welding head reference See pages 38 to 41

V32 Rotation speed (high) 999

50

then 0

/M 1 70

V33 Rotation speed (base) 999

50

then 0

/M 1 50

Wire

R40 Type of wire feeder A or B See page 42

T40 Wire start 40 0 S 1 3

V42 Wire speed (high) 999

50 (a)

then 0

/M 1 200

V43 Wire speed (base) 999

50 (a)

then 0

/M 1 200

N40 Wire stop 9999 1 D 1 360

T41 Delay for wire retract 9,9 0 S 0,1

2

Take care : 50*, 10*, 15*, 5*,4* et 0,1* = values for 50 A range

(a) At 0, a pulsed speed can lead to a cumulated error because of the overrun at each stop. In this case, it will

be necessary via programming to add a correction factor due to overrun of the pulsing frequency and the value

of high speed.

Loading...

Loading...