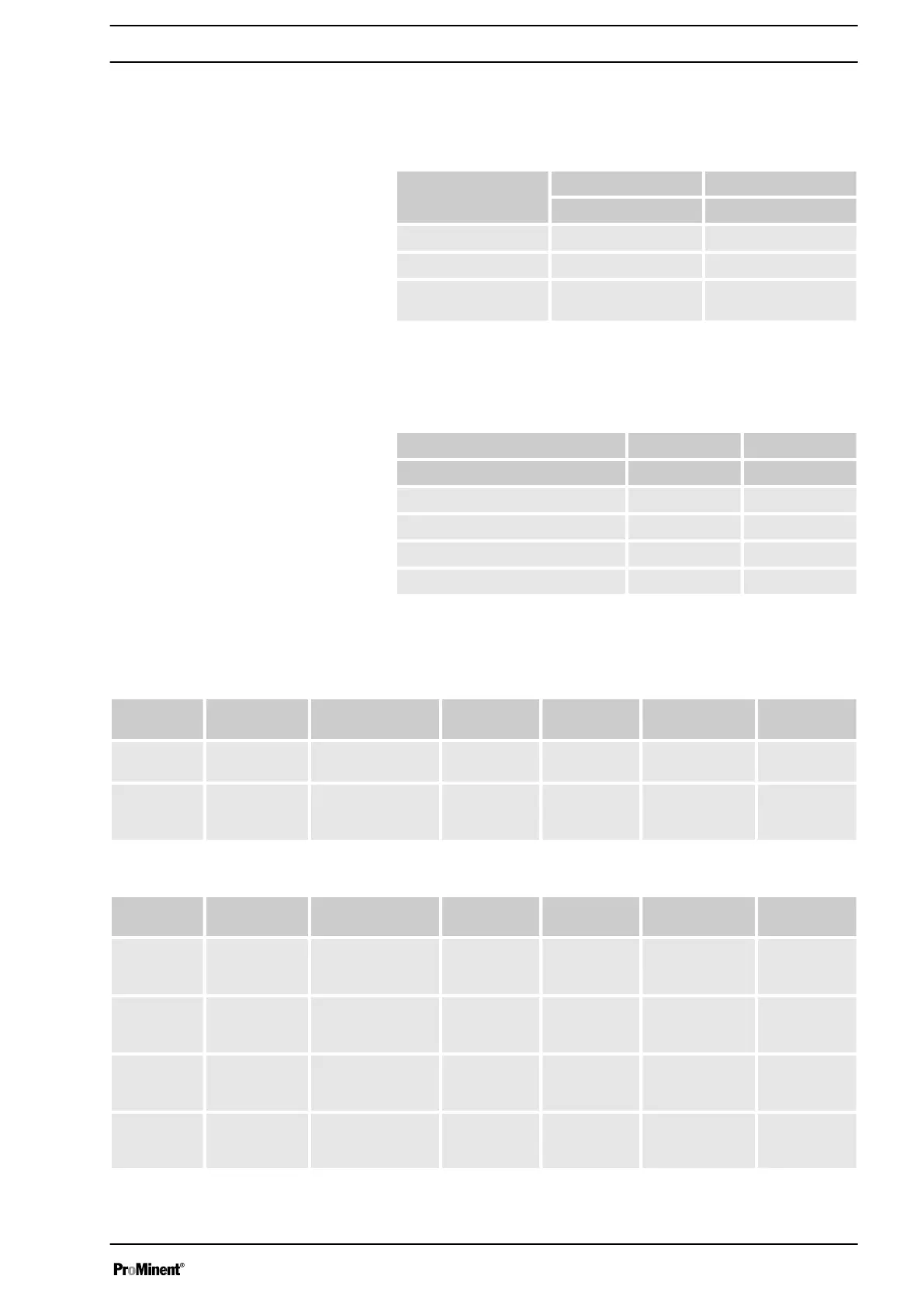

16.2 Viscosity

The liquid ends are suitable for the following viscosity ranges:

Version Stroke rate, max. Viscosity

Strokes/min mPas

Standard 180 0 ... 200

With valve springs 130 200 ... 500

With valve springs and

suction-side feed

90 500 ... 1000*

* Only when the installation is correctly adjusted

16.3

Shipping weight

Types Material version Shipping weight

kg

120145; 120190; 120270 PVT 26.1

SST 32.5

070410; 070580; 040830 PPT, PCT, PVT 29.5

SST 41.5

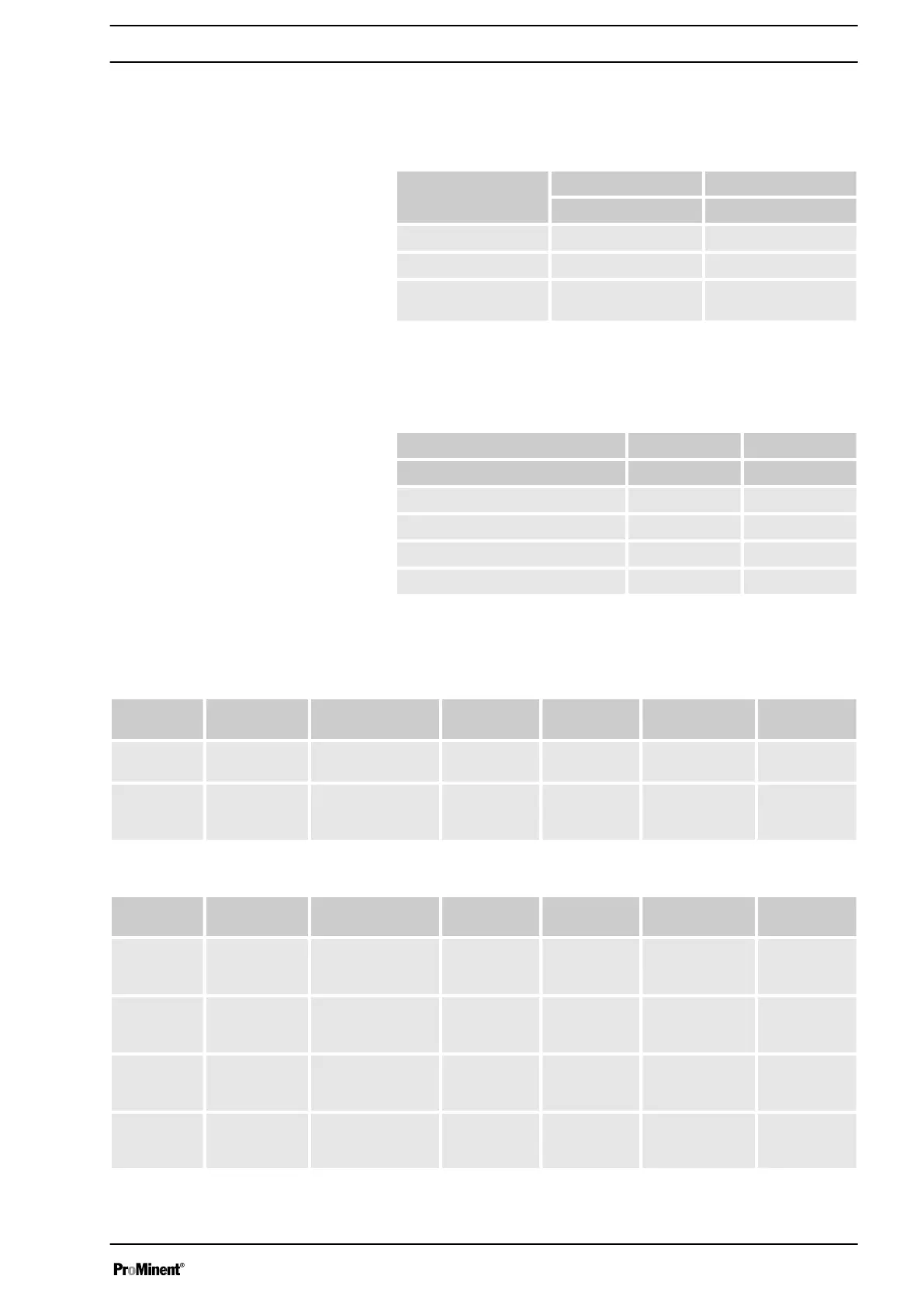

16.4 Wetted materials

Tab. 11: DN 25 ball valves

Material ver‐

sion

Liquid end Suction/pressure

connector

Seals* Valve balls Valve seats Integral relief

valve

PVT PVDF PVDF PTFE Glass PTFE PVDF / FPM

or EPDM

SST Stainless steel

1.4404

Stainless steel

1.4581

PTFE Stainless

steel 1.4404

PTFE Stainless

steel / FPM or

EPDM

Tab. 12: DN 32 plate valves

Material ver‐

sion

Liquid end Suction/pressure

connector

Seals* Valve plates /

valve springs

Valve seats Integral relief

valve

PPT PP PP PTFE Ceramic /

hast. C +

CTFE**

PTFE PVDF / FPM

or EPDM

PCT PVC PVC PTFE Ceramic /

hast. C +

CTFE**

PTFE PVDF / FPM

or EPDM

PVT PVDF PVDF PTFE Ceramic /

hast. C +

CTFE**

PTFE PVDF / FPM

or EPDM

SST Stainless steel

1.4404

Stainless steel

1.4581

PTFE Stainless

steel

1.4404 / Hast. C

PTFE Stainless

steel / FPM or

EPDM

* Diaphragm is PTFE-coated

Technical data

87

Loading...

Loading...