"

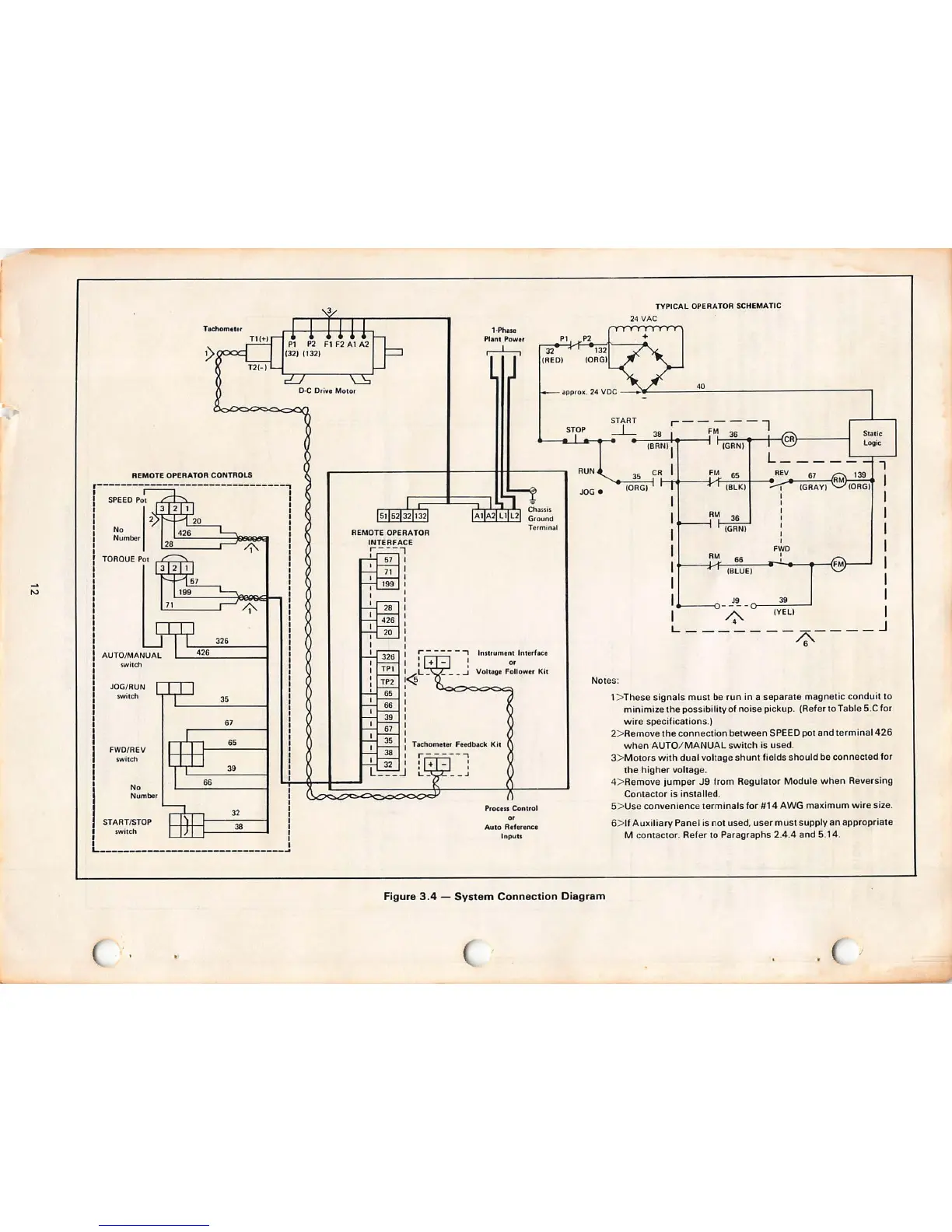

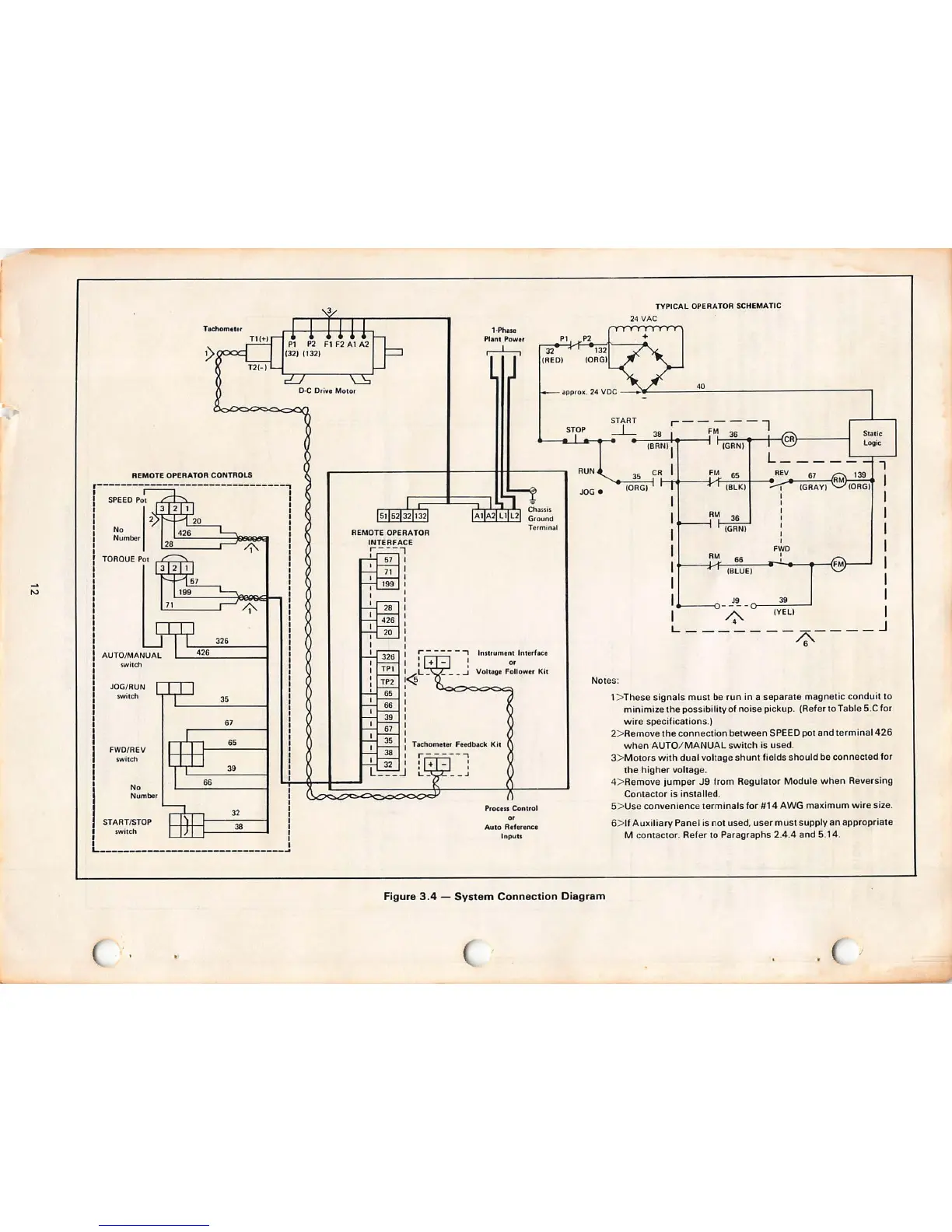

REMOTE OPERATOR CONTROLS

,--------------------------------,

No

Number

swirch

JOG/RUN

switch

FWD/REV

switch

No

Num ber

START/STOP

switch

426

326

35

67

65

39

32

38

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

L-------------------------------J

0 -C Drive Motor

51 52 32 132

REMOTE OPERATOR

INTERFACE

r----,

I 57

I

1-Phase

Ptant

Power

Pl

P2

.--1-i

32

(RED)

Terminal

Instrument Interface

or

Voltage Follower Kit

132

(ORGI

STOP

RUN

JOG•

TYPICAL OPERATOR SCHEMATIC

24 VAC

+

40

START

_L

r-----1

38 FM 36

~.=-.::.-41.,.._-+--I CR~ ------1

Stat ic

Logic

(BANI I (GANI

35

CR

I FM

65

(ORGI

(BLKI

RM

66

(BLUEi

J9

/'.;\.

L

L_

REV

I

I

I

I

I

I

I

I

FWD

I

I

39

(YELi

67

(GRAY)

1

I

I

I

I

I

I

I

I

I

_J

~----

Notes:

Tachometer Feedback Kit

r------,

I

Process Control

or

Auto

Rtf erenct

Inputs

Figure 3.4 - System Connection Diagram

1 > The se signals must be run in a separate magnetic condu it to

minimize th e possibility of noise pickup. (Refer to Table 5.C for

wire specifications .)

2> Remove th e con nection between SPEED pot and terminal 426

when AUTO / MANUAL switch is used .

3> Motors with dual voltage shunt fields should be conn ected for

the higher voltage.

4> Remove jump er J9 from Regu lator Module when Reversing

Contactor is installed.

S> Use convenienc e termina ls for

#14 AWG maximum wire size.

6> 11 Auxiliary Panel is not used , user must supply an appropriate

M con tactor . Refer to Paragraphs 2.4.4 and 5.14 .

/

Loading...

Loading...