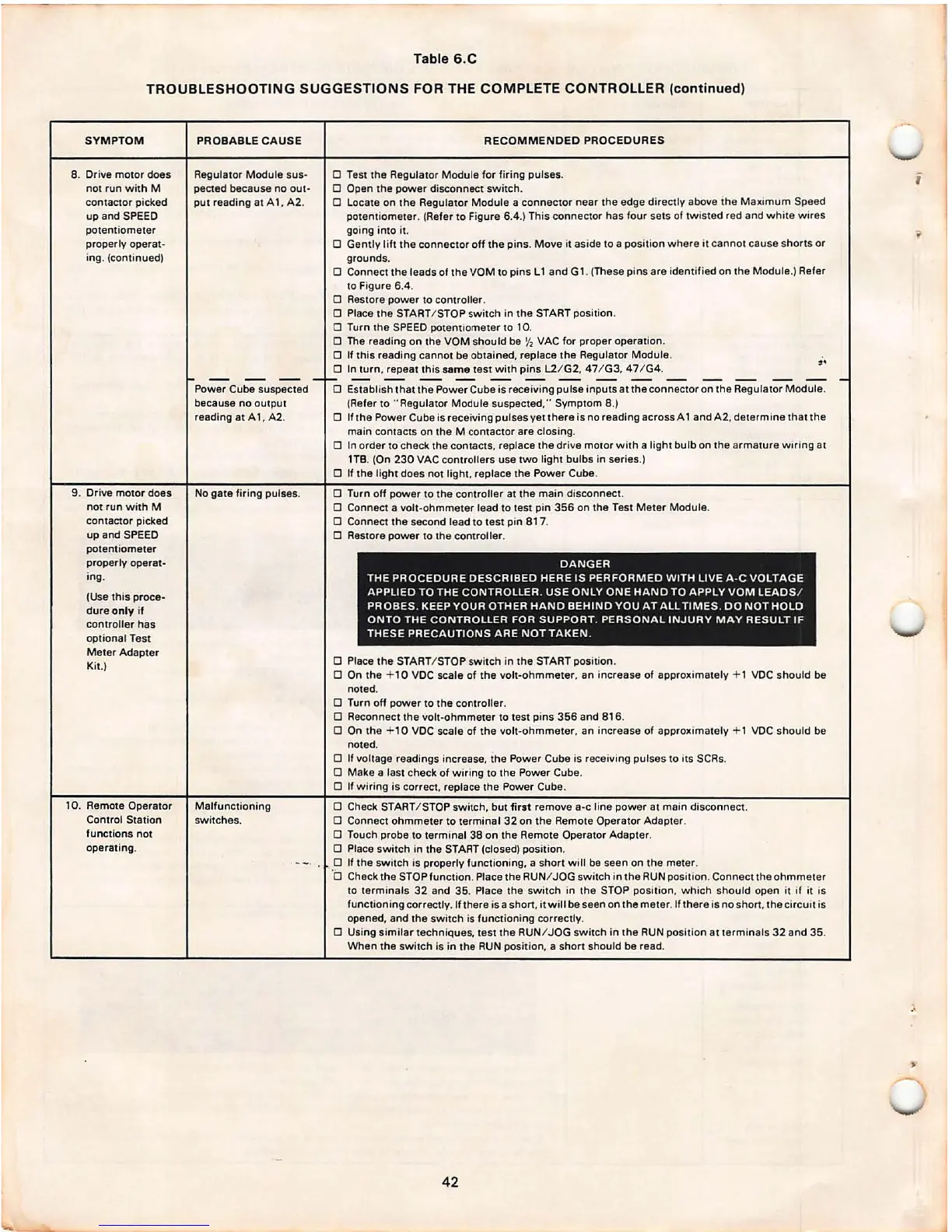

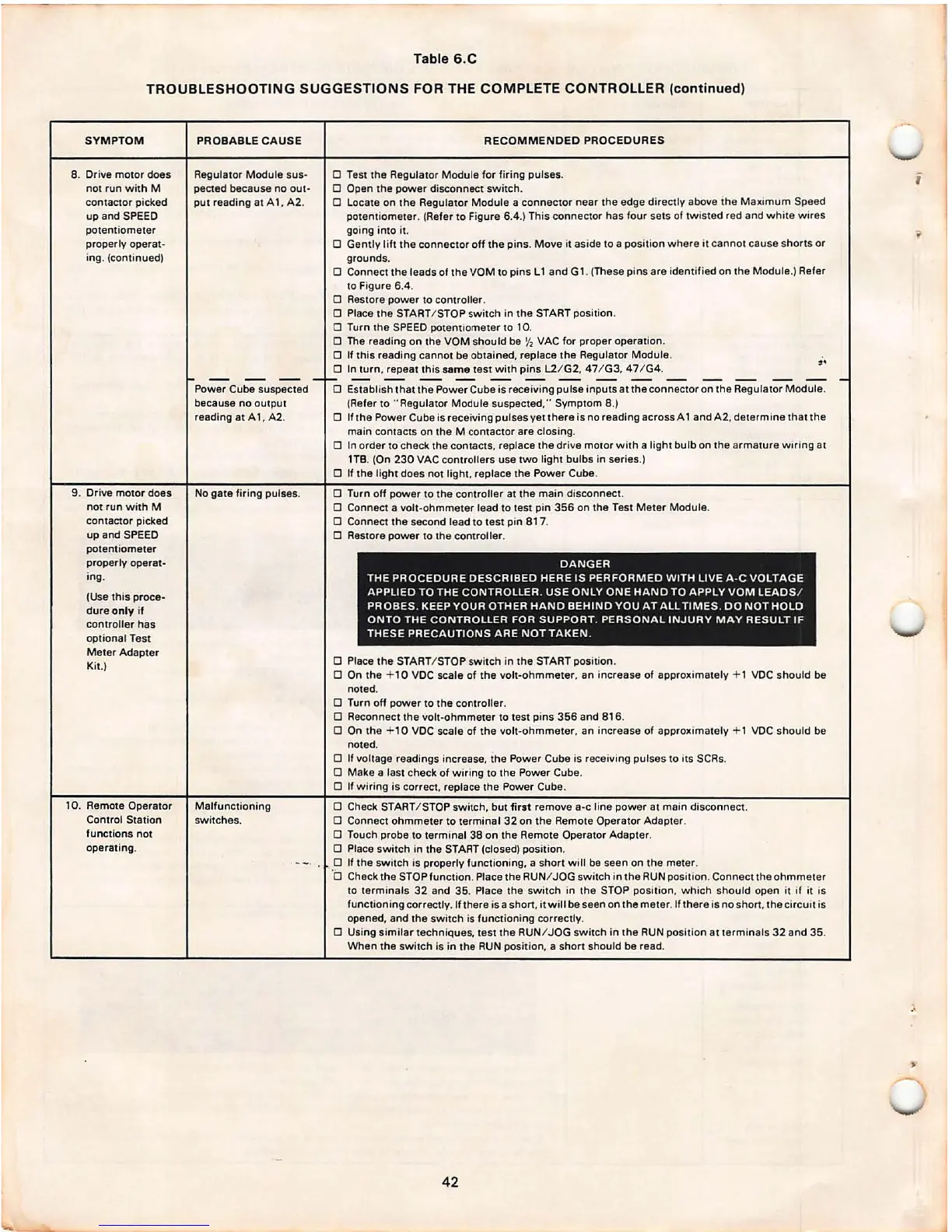

Table 6.C

TROUBLESHOOTING SUGGESTIONS FOR THE COMPLETE CONTROLLER (continued)

SYMPTOM

8. Drive motor does

not run with

M

contactor picked

up and SPEED

potentiometer

properly operat-

ing. (continued)

9. Drive motor does

not run with

M

contactor picked

up and SPEED

potentiometer

properly operat-

ing.

(Use this proce-

dure

only if

controller has

optional Test

Meter Adapter

Kit.)

1 0. Remote Operator

Control Station

functions not

operating.

PROBABLE CAUSE

Regulator Module sus-

pected because no out -

put reading at A 1, A2 .

Power Cube suspected

because no output

reading at A 1. A2.

No

gate firing pulses .

Malfunctioning

switches .

RECOMMENDED PROCEDURES

D Test the Regulator Module for fir ing pulses .

D Open the power disconnect swi tch.

D Locate on the Regulator Module a connector near the edge directly above the Maximum Speed

potentiometer . (Refer to Figure 6.4.) This connector has four sets of twi sted red and whi te w ires

going into it.

D Gently I ift the connector off the pins . Move it aside to a position w here it cannot cause shorts or

grounds .

D Connect the leads of the VOM to pins L 1 and G 1. (These pins are identified on the Module.) Refer

to Figur e 6.4 .

D Restore power to controller .

D Place the START / STOP switch in the START position.

D Turn the SPEED potentiometer to 10.

D The reading on the VOM should be \/

2

VAC for proper operation .

D If this reading cannot be obtained , replace the Regulator Module.

D In turn . repeat this same test with pins l2 / G2. 47 / G3. 47/ G4.

D Establish that the Power Cube is receiving pulse in puts at the conn ector on the Regul ator Module .

(Refer to "Regulator Module suspected," Symptom 8.)

D If the Power Cube is receiving pulses yet there is no reading across A 1 and A2 . dete rmin e that the

main contacts on the M contactor are closing .

D In order to check the contacts. replace the drive motor wi th a light bulb on the armat ure wiri ng at

1TB. (On 230 VAC controllers use two light bulbs in series .)

D If the light does not light. replace the Power Cube.

D Turn off power to the controller at the main disconnect .

D Connect a volt-ohmmeter lead to test pin 356 on the Test Meter Module .

D Connect the second lead to test pin 817 .

D Restore power to the controller .

DANGER

THE PROCEDURE DESCRIBED HERE IS PERFORMED WITH LIVE A-C VOLTAGE

APPLIED TO THE CONTROLLER . USE ONLY ONE HAND TO APPLY VOM LEADS /

PROBES. KEEP YOUR OTHER HAND BEHIND YOU AT ALL TIMES . DO NOT HOLD

ONTO THE CONTROLLER FOR SUPPORT . PERSONAL INJURY MAY RESULT IF

THESE PRECAUTIONS ARE NOT TAKEN.

D Place the START / STOP switch in the START position .

D On the + 10

voe scale of the volt-ohmmeter . an increase of approximatel y + 1 VOC should be

noted.

D Turn off

power to the controller .

D Reconnect the volt-ohmmeter to test pins 356 and 816.

D On the + 10

voe scale of the volt-ohmmeter . an increase of approximately +1 VDC should be

noted.

D If voltage readings increase, the Power Cube is receiving puls es to its SCRs.

D

Make a last check of wiring 10 the Power Cube.

D

If wiring is correct, replace the Power Cube.

D Check START / STOP switch, but

first remove a-c line power at main disconnec t.

D Connect ohmmeter to terminal 32 on the Remote Operator Adapter .

D Touch probe to terminal 38 on the Remote Operator Adapter .

D Place switch in the START (closed) position.

D

If the switch is properly functioning , a short will be seen on the meter .

·o Check the STOP function . Place the RUN/ JOG sw itch in the RUN position. Connect the ohmmete r

to terminals 32 and 35 . Place the switch in the STOP posit ion. whic h should open it if it is

functioning correctly . If there isa short. it will be seen on the meter .

If there is no short . the circu it is

opened. and the switch is functioning correct ly.

D Using similar techniques , test the RUN/ JOG sw itch in the RUN posit ion at termin als 32 and 35 .

When the switch is in the RUN position , a short should be read.

42

i

>

Loading...

Loading...