'

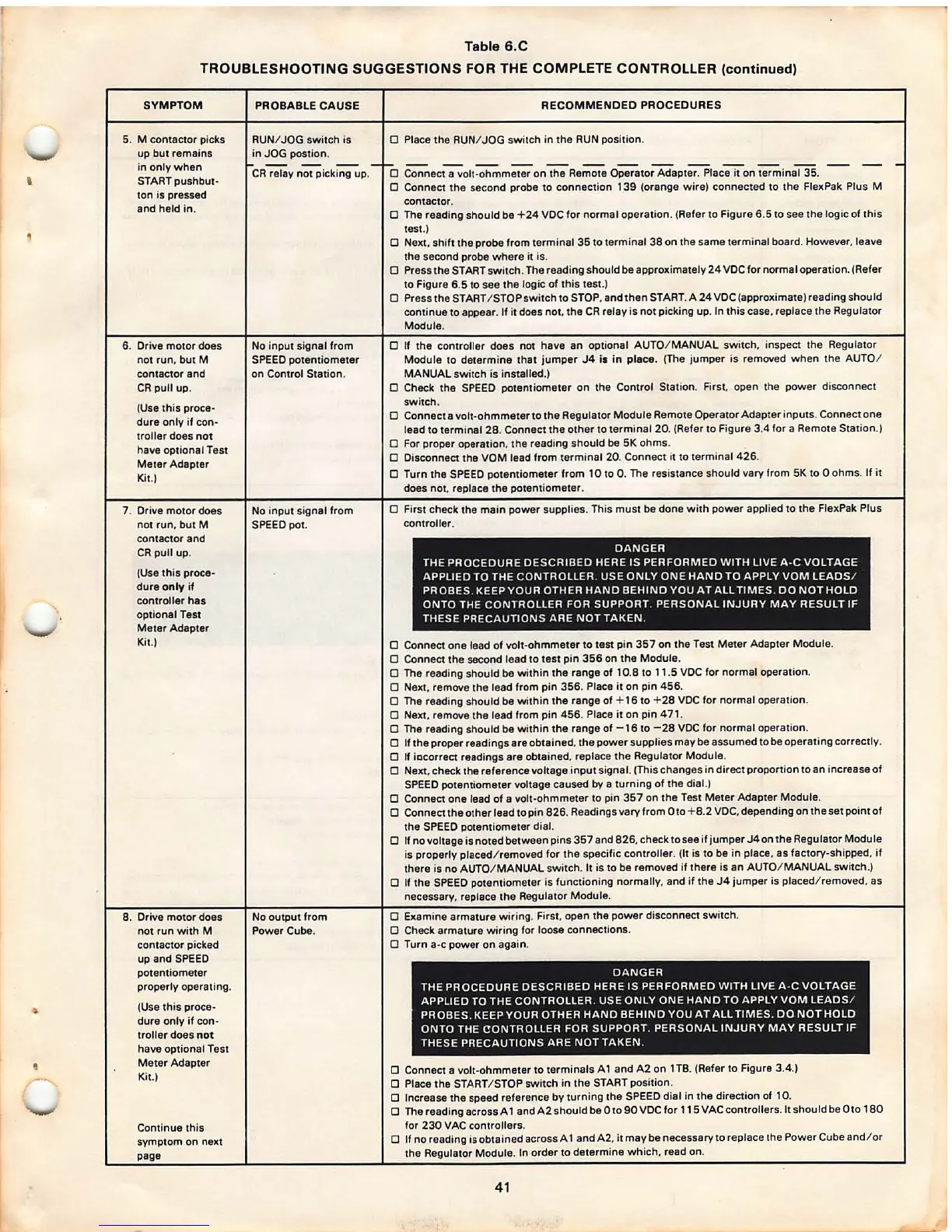

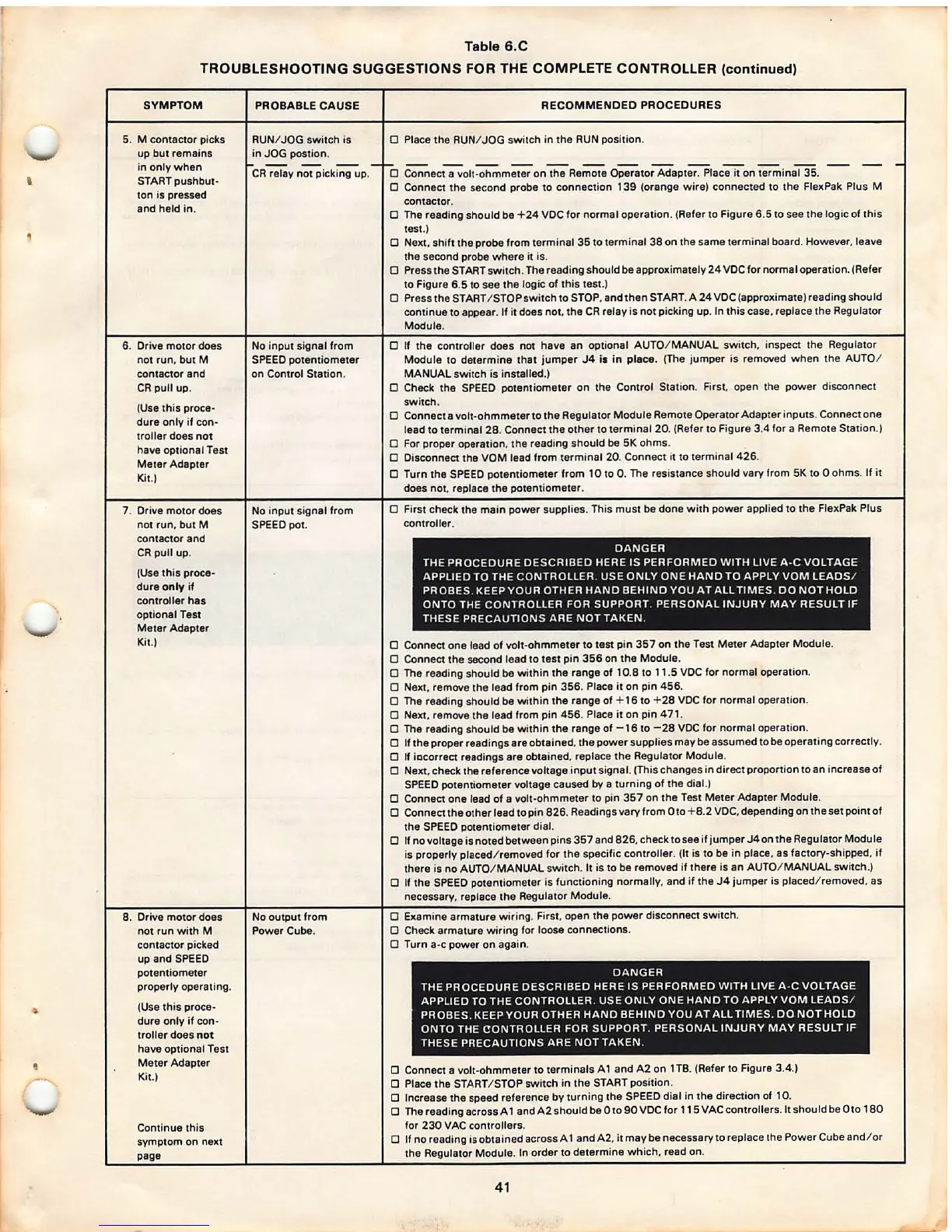

Table 6.C

TROUBLESHOOTING SUGGESTIONS FOR THE COMPLETE CONTROLLER (continued)

SYMPTOM

5.

M contactor picks

up but remains

in only when

START pushbut-

ton is pressed

and held in .

6. Drive motor does

not run, but M

contactor and

CR pull up.

(Use this proce-

dure only if con·

troller does not

have optional Test

Meter Adapter

Kit.)

7. Drive motor does

not run. but

M

contacto r and

CR pull up.

(Use this proce -

dure

only if

controller

has

optional Test

Meter Adapter

Kit.)

8. Drive motor does

not run with

M

contactor picked

up and SPEED

potentiometer

properly operat ing.

(Use this proce-

dure only if con-

tro ller does

not

have optional Test

Meter Adapter

Kit.)

Continue this

symptom on next

page

PROBABLE CAUSE

RUN/ JOG switch is

in JOG postion .

CR relay not picking up.

No input signal from

SPEED potentiom eter

on Control Station .

No input signal from

SPEED pot.

No output from

Power Cube.

RECOMMENDED PROCEDURES

D Place the RUN/ JOG switch in the RUN position.

D

Connec~olt -ohmm;;;;; on the Re~ Operator Adapt;:i;lac-;;Tt°on wminal 35 . -- --

0 Connect th e second probe to connection 139 (orange wi re) connected to the FlexPak Plus M

contac tor.

0 The reading should be +24 VDC for normal operation. (Refer to Figure 6.5 to see the logic of this

test.)

D

Next, shift the probe from terminal 35 to terminal 38 on the same termina l board. However , leave

the second probe where it is.

D Press the ST ART switc h. The reading should be approximately 24 VDC for normal operation . (Refer

to Figure 6.5 to see the logic of this test .)

D Press the START / STOP switch to STOP. and then START. A 24 VOC (approximate) reading should

conti nue to appear . If it does not. the CR relay is not picking up. In this case. replace the Regulator

Module.

D If the controller does not have an optional AUTO/ MANUAL switch , inspect the Regulator

Module to determine that jumper J4 i1 in

piece . (The jumper is removed when the AUTO/

MANUAL swi tch is installed.)

D Check the SPEED potentiometer on the Control Station.

First. open the power disconnect

switch .

D Connect a volt-ohmmeter to the Regulator Module Remote Operator Adapter inputs . Connect one

lead to terminal 28. Connect the other to terminal 20. (Refer to Figure 3.4 for a Remote Station .)

D For proper operation. the reading should be 5K ohms .

D Disconnect the VOM lead from terminal 20. Connect it to terminal 426 .

D Turn the SPEED potentiometer from 10 to 0. The resistance should vary from 5K to O ohms. If it

does not, replace the potentiomete r.

D First check the main

power supplie s. This must be done with power applied to the FlexPak Plus

controller .

DANGER

THE PROCEDURE DESCRIBED HERE IS PERFORMED WITH LIVE A ·C VOLTAGE

APPLIED TO THE CONTROLLER. USE ONLY ONE HAND TO APPLY VOM LEADS /

PROBES . KEEP YOUR OTHER HAND BEHIND YOU AT ALL TIMES. DO NOT HOLD

ONTO THE CONTROLLER FOR SUPPORT. PERSONAL INJURY MAY RESULT IF

THESE PRECAUTIONS ARE NOT TAKEN.

D Connect one lead of volt-ohmmeter to test pin 357 on the Test Meter Adapter Module.

D Connect the second lead to test pin 356 on the Module .

D The reading should be within the range of 10.8 to 11.5 VDC for normal operation .

D Next. remove the lead from pin 356 . Place it on pin 456.

D The reading should be within the range of + 16 to + 28 VOC for normal operation.

D

Next, remove the lead from pin 456 . Place it on pin 471 .

D The reading should be within the rang e of -16 to - 28 VOC for normal operation.

D If th e proper reading s are obtained. the power supplie s may be assumed to be operating correctly.

D

If iacorrect readings are obtained, replace the Regulator Module .

D

Next. check the ref erence voltage input signal. (Thi s chang es in direct proportio n to an increase of

SPEED potentiometer voltage caused

by a turning of the dial.)

D Connect one lead of a volt-ohmm eter to pin 357 on the Test Meter Adapter Module .

D Connect the other lead to pin 826 . Readings vary from Oto + 8.2 VDC, depending on the set point of

the SPEED potentiometer dial.

D If no voltage is noted between pins 357 and 826 , check to see if jump er J4 on the Regulator Module

is properly placed/ removed for the specific controller . (It is to be in place, as factory -shipped, if

there is no AUTO/ MANUAL switch . It is to be removed if there is an A UTO/ MANUAL switch.)

D If the SPEED potentiomete r is functioning normally , and if the J4 jumper is placed/ removed, as

necessary, replace the Regulator Module .

D Examine armatur e wiring . First. open the power disconnect switc h.

D Check armature wiring for loose connections.

D Turn a-c power on again .

DANGER

THE PROCEDURE DESCRIBED HERE IS PERFORMED WITH LIVE A -C VOLTAGE

APPLI ED TO THE CONTROLLER. USE ONLY ONE HAND TO APPLY VOM LEADS /

PROBES . KEEP YOUR OTHER HAND BEHIND YOU AT ALL TIMES. DO NOT HOLD

ONTO THE

CONTROLLER FOR SUPPORT. PERSONAL INJURY MAY RESULT IF

THESE PRECAUTIONS ARE NOT TAKEN.

D Connect a volt-ohmmeter to terminals A 1 and A2 on 1 TS. (Refer to Figure 3.4.)

0 Place the START/ STOP switch in the START position .

D Increase the speed reference by turning the SPEED dial in the direction of 10.

O The reading across A 1 andA2shouldbe Oto90VOCfor 115VAC contr ollers. It should be Oto 180

for 230 VAC controller s.

D

If no reading is obtained across A 1 and A2, it may be necessary to replace the Power Cube and/ or

the Regulator Module. In order to determine which , read on.

41

Loading...

Loading...