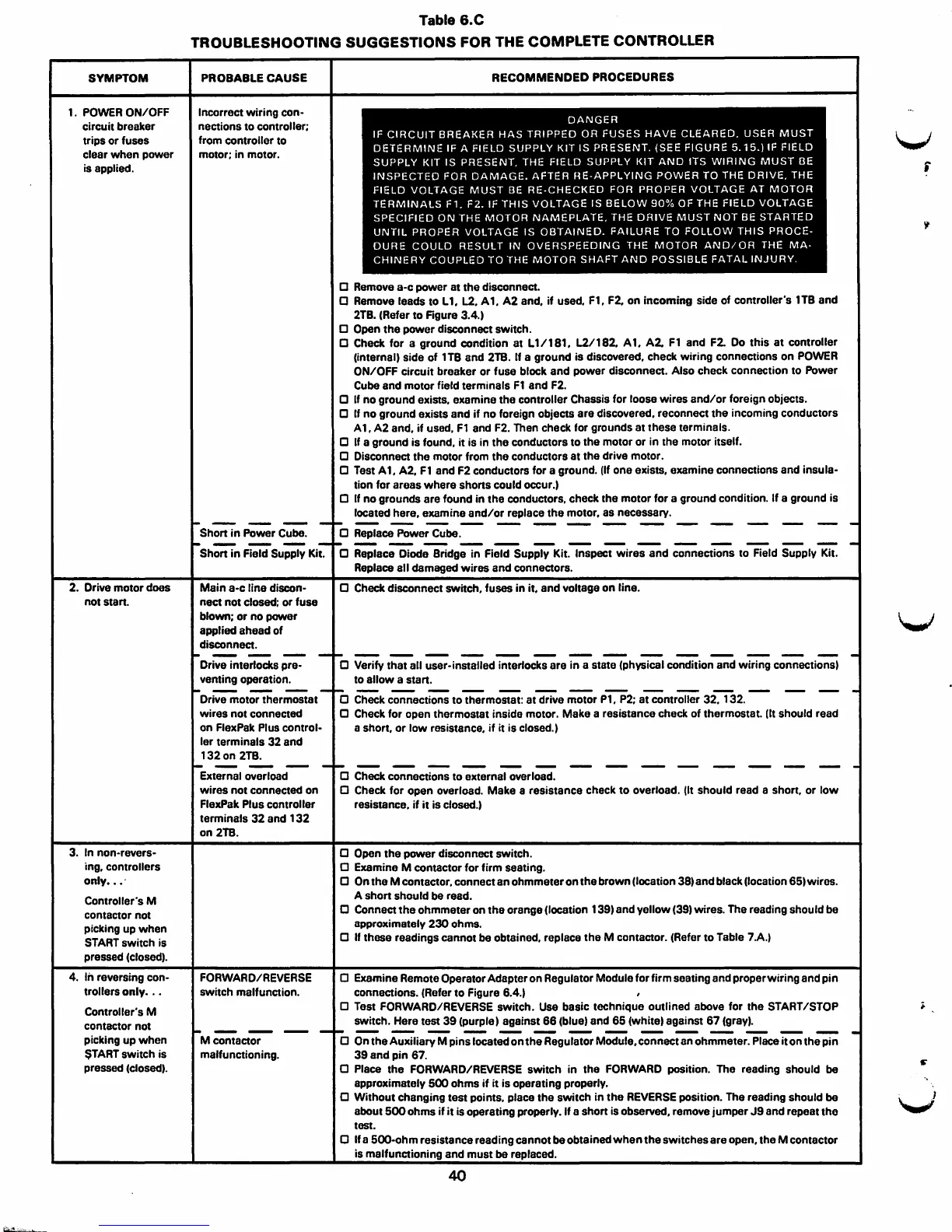

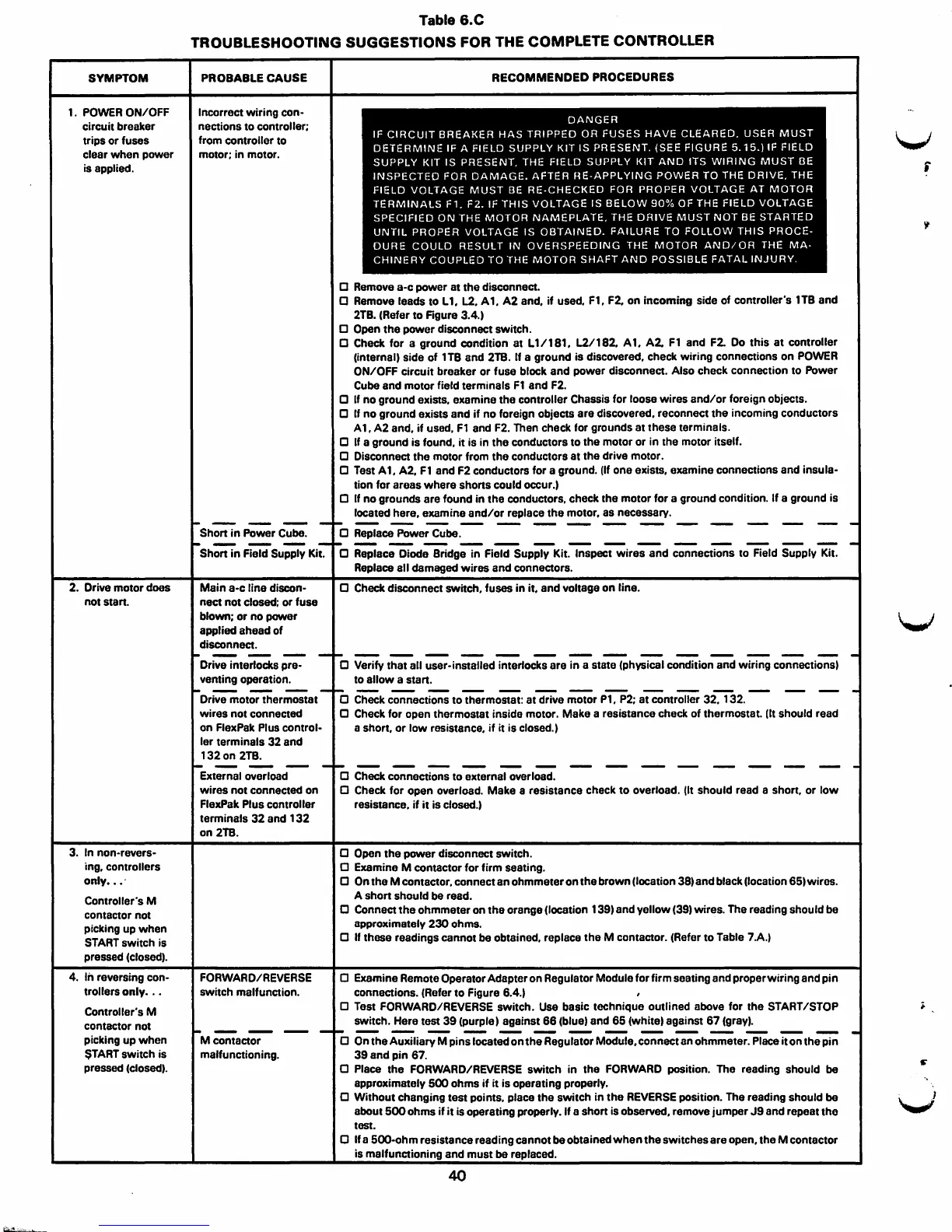

SYMPTOM

1. POWER ON/OFF

circuit breaker

trips or fuses

clear when power

is applied.

2. Drive motor does

not start.

3. In non-revers-

ing, controllers

only ••• ·

Controller's M

contactor not

picking up when

START switch is

pressed (closed,.

4.

In reversing con-

trollers

only . ..

Controller's M

contactor not

picking up when

$TART switch is

pressed

(closed,.

Table 6.C

TROUBLESHOOTING SUGGESTIONS FOR THE COMPLETE CONTROLLER

PROBABLE CAUSE

Incorrect wiring con-

nections to controller;

from controller to

motor; in motor.

Short in Power Cube.

Short in Field Supply Kit.

Main a-c line discon-

nect not closed; or fuse

blown; or no power

applied ahead of

disconnect.

Drive interlocks pre-

venting operation.

Drive motor thermostat

wires not connected

on FlexPak Plus control-

ler terminals 32 and

132on 2TB.

External overload

wires not connected on

FlexPak Plus controller

terminals 32 and 132

on 2TB.

FORVVARD/REVERSE

switch malfunction.

Mcontactor

malfunctioning.

RECOMMENDED PROCEDURES

DANGER

IF CIRCUIT BREAKER HAS TRIPPED OR FUSES HAVE CLEARED. USER MUST

DETERMINE IF A FIELD SUPPLY KIT IS PRESENT. (SEE FIGURE 5.15.) IF FIELD

SUPPLY KIT IS PRESENT. THE FIELD SUPPLY

KIT AND 1TS WIRING MUST OE

INSPECTED FOR DAMAGE. AFTER HE-APPLYING POWER TO THE DRIVE. THE

FIELD VOLTAGE MUST BE RE-CHECKED FOR PROPER VOLTAGE AT MOTOR

TERMINALS F1. F2. IF THIS VOLTAGE IS BELOW 90% OF THE FIELD VOLTAGE

SPECIFIED ON THE MOTOR NAMEPLATE, THE DRIVE MUST NOT BE STARTED

UNTIL PROPER VOLTAGE IS OBTAINED. FAILURE TO FOLLOW THIS PROCE-

DURE COULD RESULT IN OVERSPEEDING THE MOTOR ANO/OR THE MA-

CHINERY COUPLED TO THE MOTOR SHAFT ANO POSSIBLE FATAL INJURY.

a Remove a-c power at the disconnect.

a Remove leads to L1. L2. A1. A2 and, if used, F1, F2. on incoming side of controller's 1TB and

2TB. (Refer to Figure

3.4.,

a Open the power disconnect switch.

a Check for a ground condition at L1/181, L2/182. A1. A2. F1 and F2. Do this at controller

(internal, side of 1TB and 2TB. If a ground is discovered, check wiring connections on POWER

ON/OFF circuit breaker or fuse block and power disconnect. Also check connection to Power

Cube and motor field terminals F1 and F2.

a If no ground exists, examine the controller Chassis for loose wires and/or foreign objects.

a If no ground exists and if no foreign objects are discovered. reconnect the incoming conductors

A 1, A2 and, if used, Fl and F2. Then check for grounds at these terminals.

0 If a ground is found, it is in the conductors to the motor or in the motor itself.

a Disconnect the motor from the conductors at the drive motor.

a Test A 1, A2, F1 and F2 conductors for a ground. (If one exists, examine connections and insula-

tion for areas where shorts could occur.,

a If no grounds are found in the conductors, check the motor for a ground condition. If a ground is

located here,

examine and/or replace the motor, as necessary.

a Replace Power Cube.

a Replace Diode Bridge in Field Supply Kit. Inspect wires and connections to Field Supply Kit.

Replace all damaged wires and connectors.

a Check disconnect switch, fuses in it, and voltage on line.

0 Verify that all user-installed interlocks are in a state (physical condition and wiring connections,

to allow a start.

-------- ----------- --

a Check connections to thermostat: at drive motor P1, P2; at controller 32. 132.

0 Check for open thermostat inside motor. Make a resistance check of thermostat. (It should read

a short, or low resistance, if it is

closed.)

a Check connections to external overload.

0 Check for open overload. Make a resistance check to overload. (It should read a short, or low

resistance, if it is closed.)

a Open the power disconnect switch.

0 Examine M contactor for firm seating.

0 On the M contactor, connect an ohmmeter on the brown (location 38, and black (location 65, wires.

A short should be read.

0 Connect the ohmmeter on the orange (location 139, and yellow (39, wires. The reading should be

approximately 230 ohms.

a If these readings cannot be obtained, replace the M contactor. (Refer to Table 7.A.)

D Examine Remote Operator Adapter on Regulator Module for firm seating and proper wiring and pin

connections. (Refer to Figure 6.4.)

D Test FORVVARO/REVERSE switch. Use basic technique outlined above for the START /STOP

switch. Here test 39 (purple) against 66 (blue, and 65

(white, against 67 (gray,.

a On the Auxiliary M pins located on the Regulator Module, connect an ohmmeter. Place it on the pin

39 and pin 67.

0 Place the FORVVARD/REVERSE switch in the FORVVARD position. The reading should be

approximately 500 ohms if it is operating properly.

a Without changing test points. place the switch in the REVERSE position. The reading should be

about 500 ohms

if it is operating properly. If a short is observed, remove jumper J9 and repeat the

test.

0 If a 500-ohm resistance reading cannot be obtained when the switches are open, the M contactor

is malfunctioning and must be replaced.

40

V

r

V

Loading...

Loading...