51

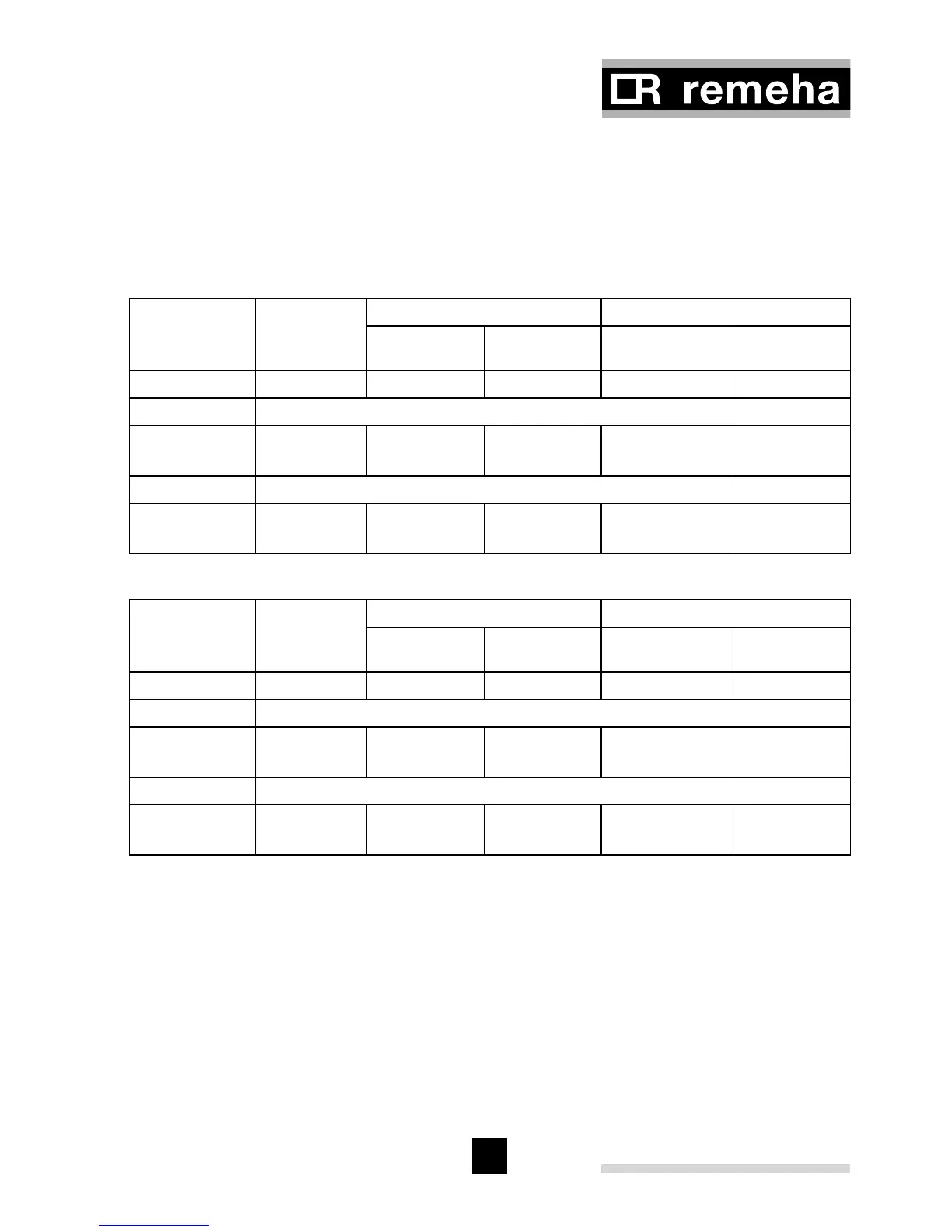

Note: When checking combustion the C0

2

levels should be in accordance with the

Table 12 (+/- 0.3%). If the levels are outside these tolerances clean heat exchanger

in accordance with the instructions in Par 11.3. If, after cleaning, the combustion fig-

ures are still outside these tolerances, then adjustments must be made to achieve the

levels in accordance with the tolerance in Table 13 (+/- 0.1%)

Fan

Speed

approx.

Natural gas Propane

CO

2

O

2

CO

2

O

2

rpm % % % %

Front panel not mounted

Part load

Full load

2300

5450

9.3 (+/- 0.3)

9.3 (+/- 0.3)

4.3 (+/- 0.4)

4.3 (+/- 0.4)

10.5 (+/- 0.3)

10.5 (+/- 0.3)

5.1 (+/- 0.4)

5.1 (+/- 0.4)

Front panel mounted

Part load

Full load

2300

5450

9.5 (+/- 0.3)

9.5 (+/- 0.3)

3.9 (+/- 0.4)

3.9 (+/- 0.4)

10.7(+/- 0.3)

10.7(+/- 0.3)

4.8 (+/- 0.4)

4.8 (+/- 0.4)

Table 12 CO

2

and O

2

percentage (checking values)

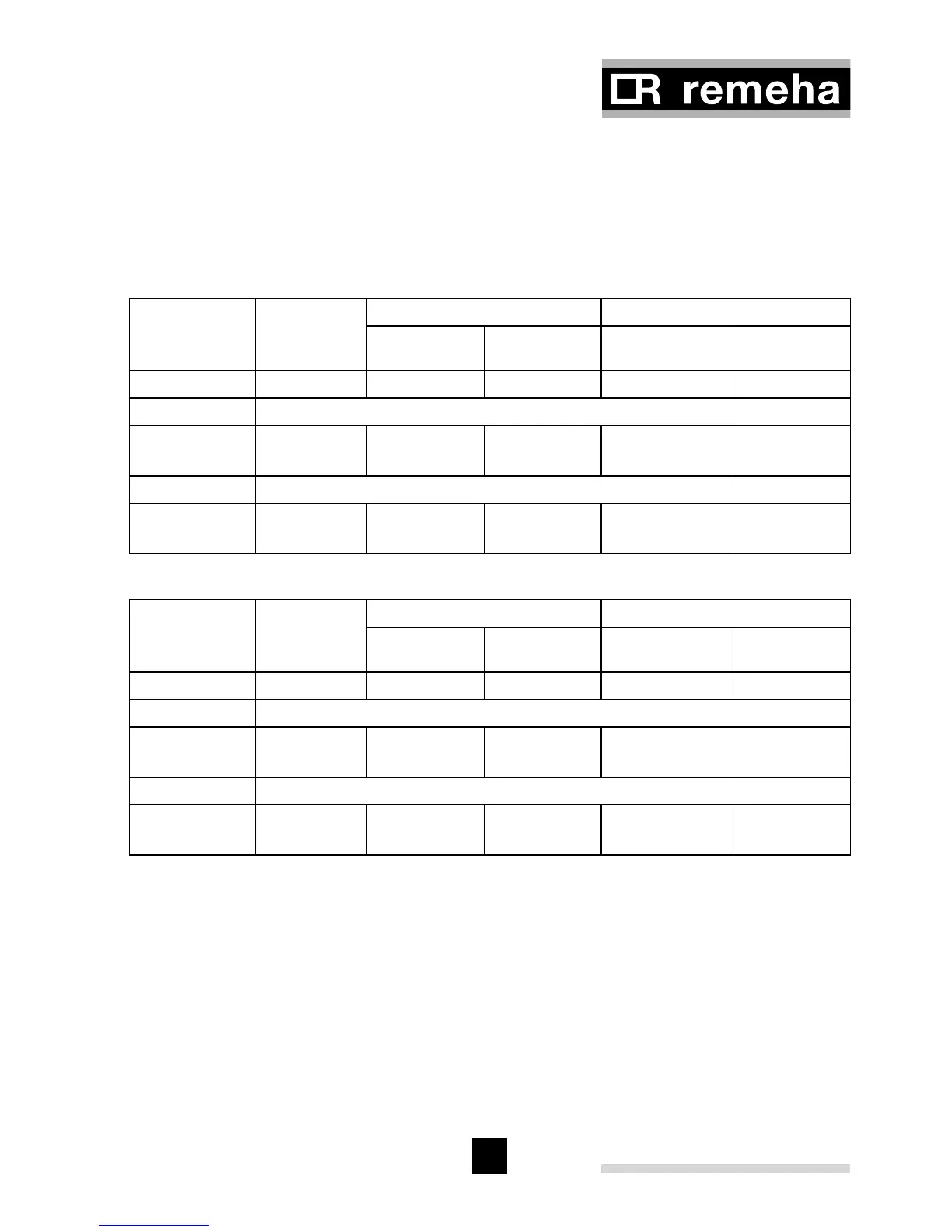

Fan

Speed

approx.

Natural gas Propane

CO

2

O

2

CO

2

O

2

rpm % % % %

Front panel not mounted

Part load

Full load

2300

5450

9.3 (+/- 0.1)

9.3 (+/- 0.1)

4.3 (+/- 0.2)

4.3 (+/- 0.2)

10.5 (+/- 0.1)

10.5 (+/- 0.1)

5.1 (+/- 0.1)

5.1 (+/- 0.1)

Front panel mounted

Part load

Full load

2300

5450

9.5 (+/- 0.1)

9.5 (+/- 0.1)

3.9 (+/- 0.2)

3.9 (+/- 0.2)

10.7(+/- 0.1)

10.7(+/- 0.1)

4.8 (+/- 0.1)

4.8 (+/- 0.1)

Table 13 CO

2

and O

2

percentage (setting values)

Attention: Make sure the opening around the probe is properly sealed off when

measuring!

The CO/CO

2

ratio should not exceed 0.02% at any time.

Maximum CO levels permitted = 100 ppm.

11.2.2 CO

2

/O

2

adjustment

The CO

2

and O

2

levels can be adjusted by following the procedure below. Any adjust-

ment required can be done via the setting screws on the gas block, see Fig. 23.

Loading...

Loading...