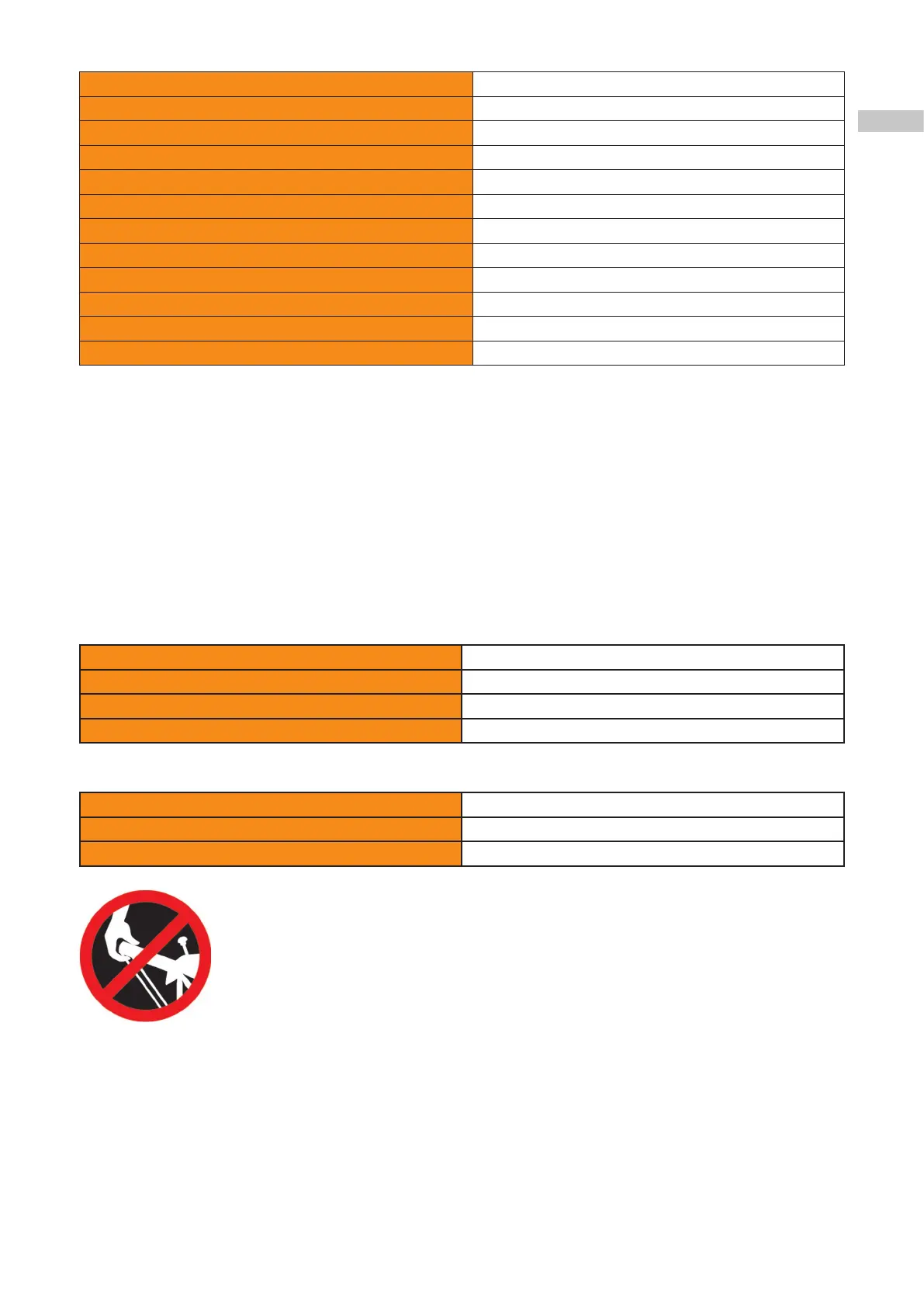

Equator 500 machine specifications

Comparison uncertainty

± 0.002 mm

Scale resolution

0.00001 mm

Maximum move velocity

750 mm/s

Maximum move acceleration

5000 mm/s

2

Storage temperature

-25 °C to +70 °C

Operating temperature

+5 °C to +50 °C

Operating humidity

Maximum 80 %RH at 40 °C, non-condensing

Machine electrical supply requirements

48 V DC supplied direct from Equator controller

Repeatability of piece part in fixture

1 mm

Maximum workpiece weight (including fixture plate)

100 kg

Protective equipment suggested*

Eye protection and safety shoes

Guards

None

The process of measuring on an Equator involves defining a series of gauge points on the component

surface. Periodic calibration of a master part on a CMM establishes datum values for each gauge point. The

same gauge points on the same master part are measured on Equator (known as ‘mastering’) to establish

a correlation with the certified CMM. Subsequently, a regular ‘re-mastering’ process is used to account for

changing environmental conditions.

Size and position measurements made immediately following re-mastering will have a comparison uncertainty

of ±0.002 mm relative to the certified measurements of the master part. This specification applies where each

part is fixtured to within 1 mm relative to the master part.

*Customers should complete their own risk assessment on delivery of the machine to define their own PPE

requirements.

Equator 500 machine specifications - Scanning

Probe type

Renishaw 3 axis SP25 analogue scanning probe

Maximum scanning velocity*

250 mm/s

Maximum scanning acceleration

1500 mm/s

2

Maximum scanning rate

2000 points/s

Equator 500 machine specifications - Touch Trigger

Probe type

Renishaw 3 axis TP20 kinematic touch-trigger probe

Maximum touch point velocity

10 mm/s

Maximum touch acceleration

1500 mm/s

2

Equator 500 machine labels

A warning label on each of the three support arms for the constraint mechanism warns

not to lift the machine by the support arms. The Equator 500 should only be lifted using

mechanical means.

* Maximum scanning speed cannot be guaranteed as it is affected by feature type/size/finish and stylus

configurations.

15

Loading...

Loading...