60

Workpiece loading

When loading a part into the working volume, first make sure that the probe is in a safe position.

The loading and unloading of parts can be achieved in several ways. Either the fixture can be released and the

part exchanged within the working volume or, alternatively, the fixture plate can be removed from the kinematic

positioning for loading/unloading external to the machine.

In order to increase the efficiency of use, a number of pre-loaded fixture plates could be queued for inspection.

Additional fixture plates are available for purchase as accessories.

Please see www.renishaw.com/equator-accessories or contact your local Renishaw representative.

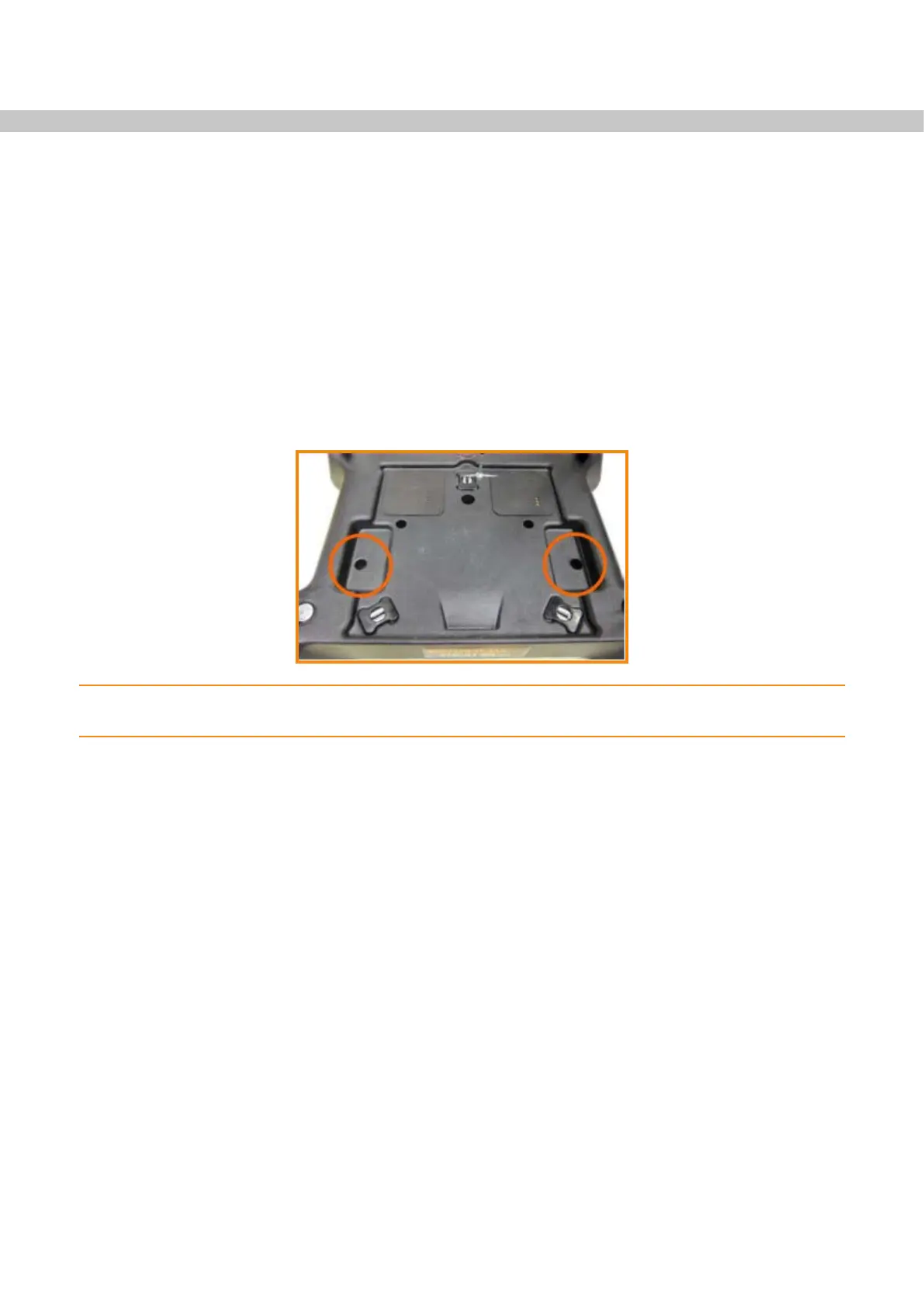

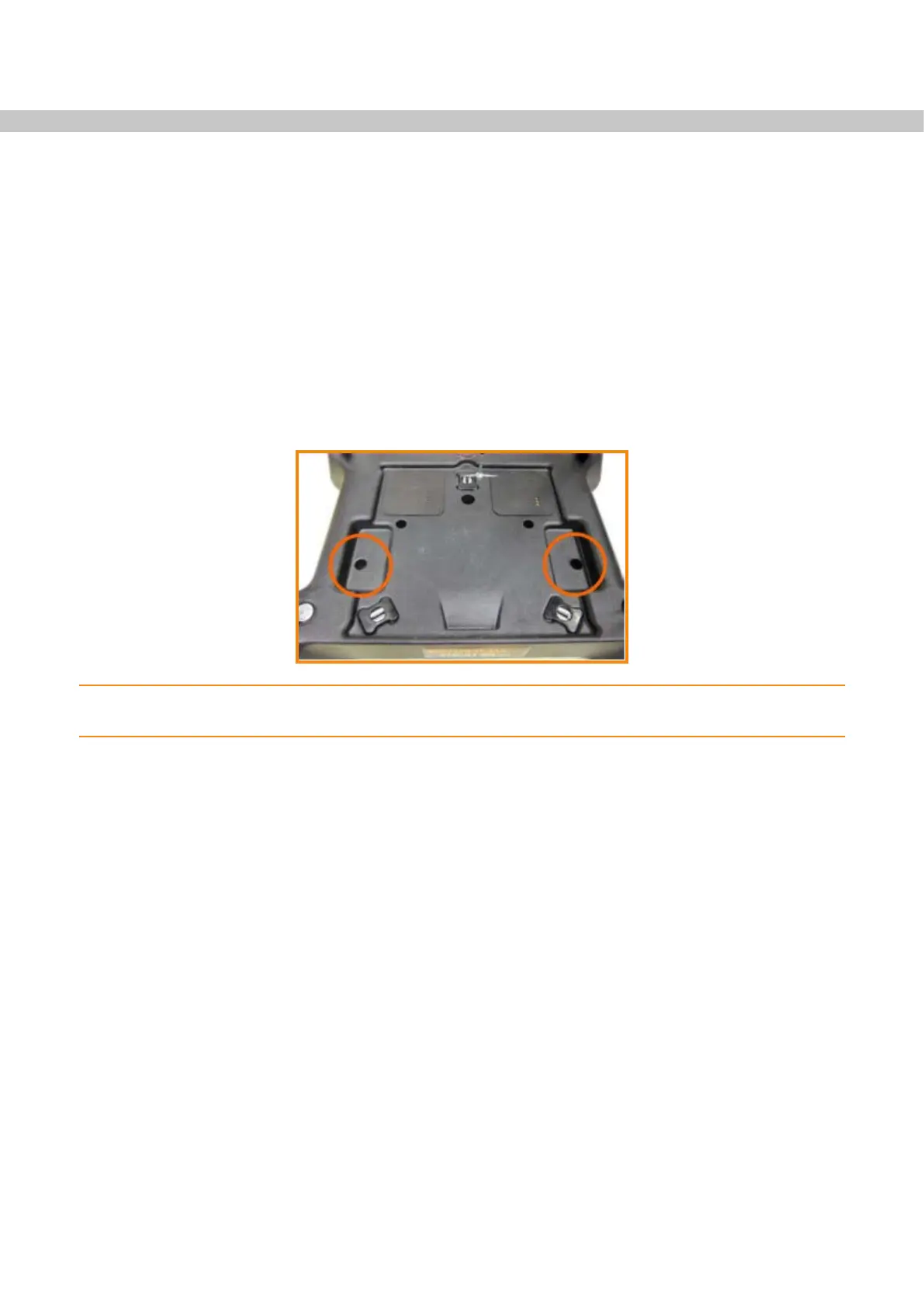

When loading a fixture plate, ensure that your hands do not get trapped under the plate by making use of the

hand holes in the base casting (see below).

NOTE: Gently attempt to move the plate once positioned. There should be no movement if the plate

is correctly loaded.

Fixture plate location

The repeatable positioning of the fixture plate on the Equator’s base casting is controlled by the kinematic

locations found on the base casting and on the underside of the fixture plate.

Use of the kinematic location minimises the requirement to carry out an initial location of a component within

the part program, thereby improving the throughput of components.

Workpiece and xture plate loading

Loading...

Loading...