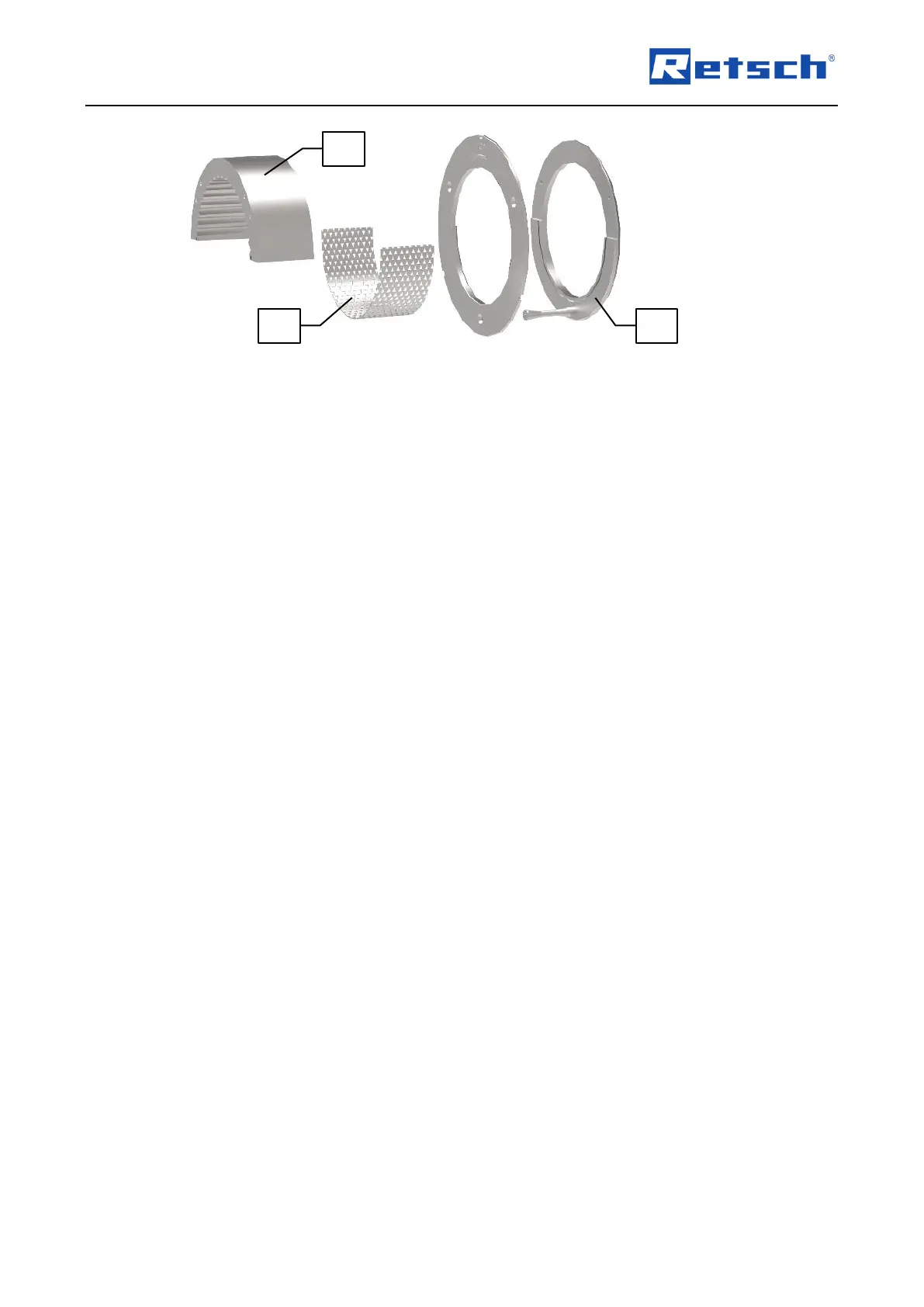

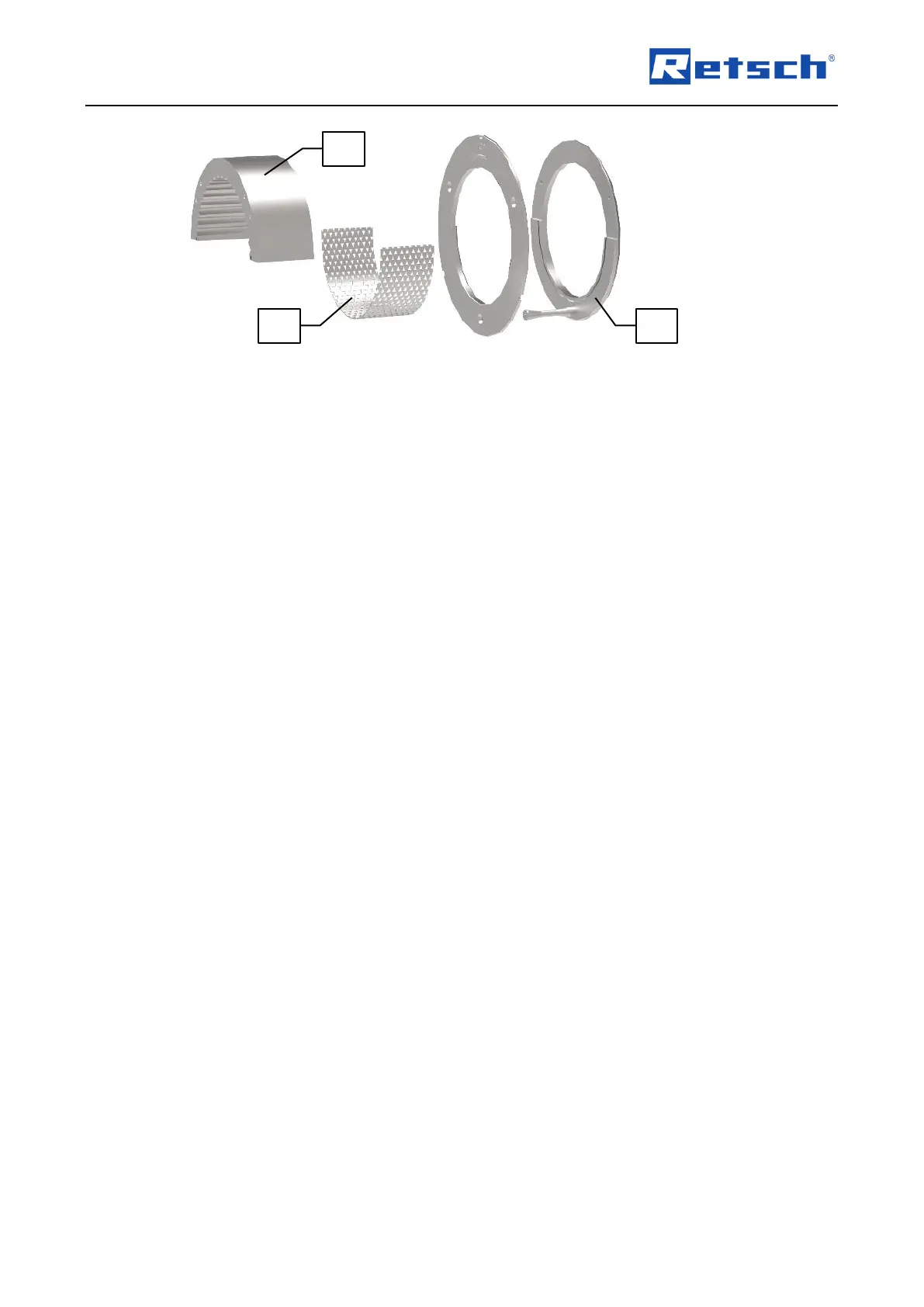

For thorough cleaning of the retaining frame for 180° sieve inserts, it is recommended to

separate the sieve insert (SBH), as well as the grinding insert (ME) from the retaining frame

(SRM).

Remove the three M5 hexagon socket countersunk head screws.

Remove the front retaining frame to remove the 180° sieve insert.

Additionally remove the two M5 hexagon socket countersunk head screws that connect the

grinding insert and the rear retaining frame.

The retaining frames (SR), (SRM), the sieve inserts (SB), (SBH), as well as the grinding insert

(ME) can be cleaned with alcohol, petrol or normal household detergent. Sieve inserts (SB),

(SBH) can be easily and effectively cleaned dry or wet with a hand brush with plastic bristles. All

parts are also dishwasher suitable.

Sieve inserts (SB), (SBH) with finer mesh sizes can also be cleaned in an ultrasonic cleaning-

bath. As cleaning agent, water together with a standard surfactant is recommended. The

cleaning in the ultrasonic bath usually takes two to three minutes. After that the sieve inserts are

thoroughly rinsed with water and dried. The cleaning with strong bases or acids is generally not

recommended.

Drying ovens of various sizes can be used for drying sieve inserts.

Additional information concerning ultrasonic cleaning-baths and drying ovens can be found on

the Retsch GmbH homepage (http://www.retsch.com).

Cleaning the rotor:

The rotor (RO) can be cleaned with alcohol, petrol or normal household detergent. The rotor is

also dishwasher suitable.

Make sure that the hub (RO1) is thoroughly cleaned and no material residues are left inside.

Loading...

Loading...