8

GAS LINE

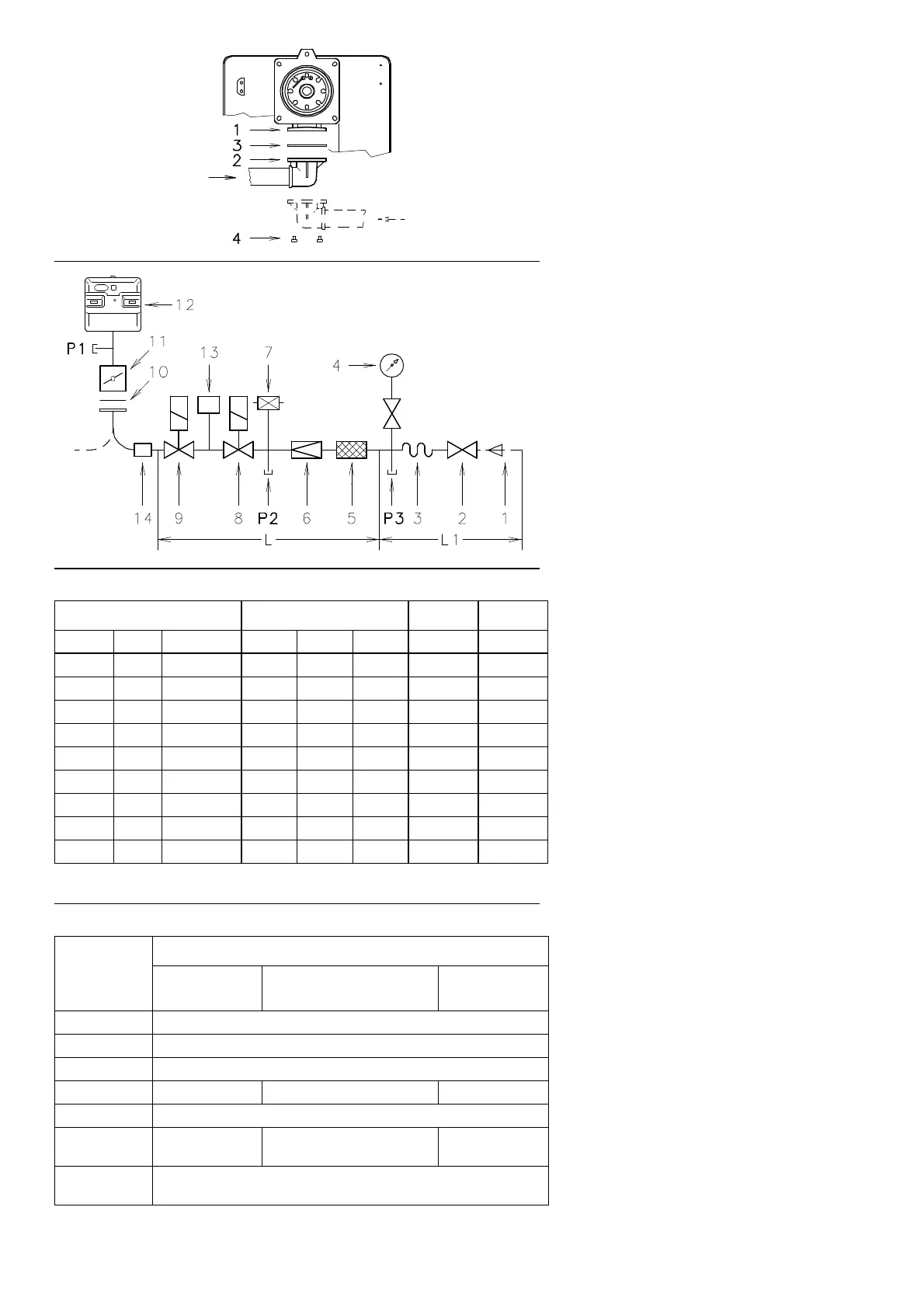

• The gas train must be connected to the gas

attachment 1)(A), using flange 2), gasket 3)

and screws 4) supplied with the burner.

• The gas train can enter the burner from the

right or left side, depending on which is the

most convenient, see fig.(A).

• Gas solenoids 8)-9)(B) must be as close as

possible to the burner to ensure gas reaches

the combustion head within the safety time

range of 3 s.

• Make sure that the pressure governor calibra-

tion range (colour of the spring) comprises the

pressure required by the burner.

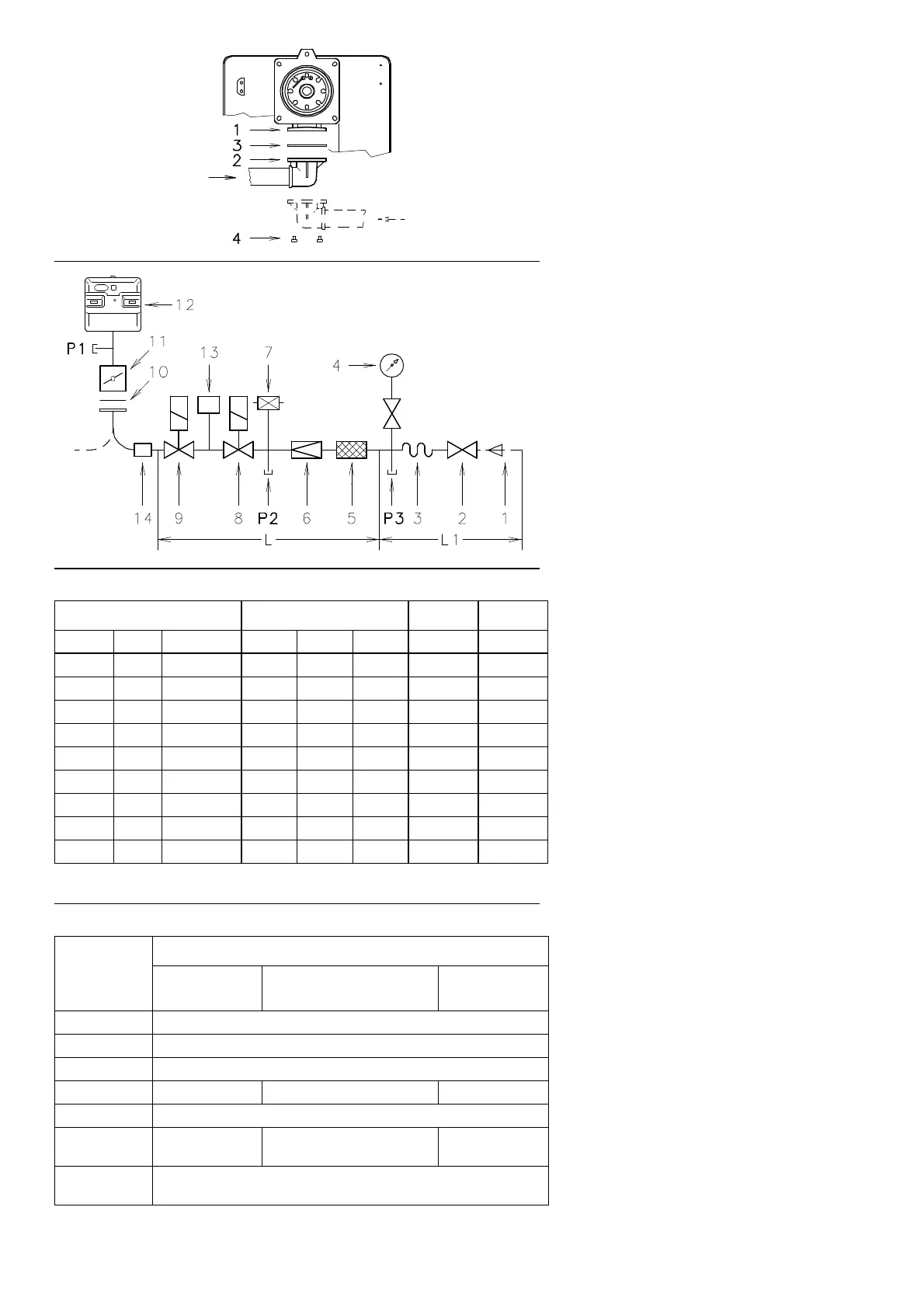

GAS TRAIN (B)

It is type-approved according to EN 676 Stand-

ards and is supplied separately from the burner

with the code indicated in Table (C).

KEY (B)

1 - Gas input pipe

2 - Manual valve

3 - Vibration damping joint

4 - Pressure gauge with pushbutton cock

5 - Filter

6 - Pressure governor (vertical)

7 - Minimum gas pressure switch

8 - Safety solenoid VS (vertical)

9 - Adjustment solenoid VR (vertical)

Two adjustments:

• ignition delivery (rapid opening)

• maximum delivery (slow opening)

10 - Standard issue burner gasket with flange

11 - Gas adjustment butterfly valve

12 - Burner

13 - Gas valve 8)-9) leak detection control

device.

In accordance with EN 676 Standards, gas

valve leak detection control devices are

compulsory for burners with maximum out-

puts of more than 1200 kW.

14 - Gas train/burner adaptor.

P1 - Pressure at combustion head

P2 - Pressure down-line from the pressure gov-

ernor

P3 - Pressure up-line from the filter

L - Gas train supplied separately with the code

indicated in Table (C)

L1 - The responsibility of the installer

KEY TO TABLE (C)

C.T. =Gas valves 8) - 9) leak detection control

devices:

- = Gas train without gas valve leak detec-

tion control device; device that can be

ordered separately and assembled sub-

sequently (see Column 13).

♦= Gas train with assembled VPS valve

leak detection control device.

13 =VPS valve leak detection control device.

Supplied separately from gas train on

request.

14 =Gas train/burner adaptor.

Supplied separately from gas train on

request.

Note

See the accompanying instructions for the

adjustment of the gas train.

(A)

(B)

(C)

GAS BURNERS AND RELEVANT GAS TRAINS APPROVED ACCORDING TO EN 676

Gas train L Burner 13 14

Ø C.T. Code RS 28 RS 38 RS 50 Code Code

3/4” − 3970076 • − − 3010123 3000824

1” − 3970077 • • • 3010123 3000824

1”

1/4

− 3970144 • • • 3010123 −

1”1/2 − 3970145 • • • 3010123 −

1”1/2 − 3970180 • • • 3010123 −

2” − 3970146 − • • 3010123 3000822

2” − 3970181 − • • 3010123 3000822

2” ♦ 3970160 − • • − 3000822

2” ♦ 3970182 − • • − 3000822

GAS TRAIN COMPONENTS

Code

Components

Filter

5

Pressure governor

6

Solenoids

8 - 9

3970076 Multiblock MB DLE 407

3970077 Multiblock MB DLE 410

3970144 Multiblock MB DLE 412

3970145 GF 515/1 FRS 515 DMV DLE 512/11

3970180 Multiblock MB DLE 415

3970146

3970160

GF 520/1 FRS 520 DMV DLE 520/11

3970181

3970182

Multiblock MB DLE 420

D505

D935

Loading...

Loading...