5

GAS PRESSURE

The adjacent tables show minimum pressure

losses along the gas supply line depending on

the burner output in 2nd stage operation.

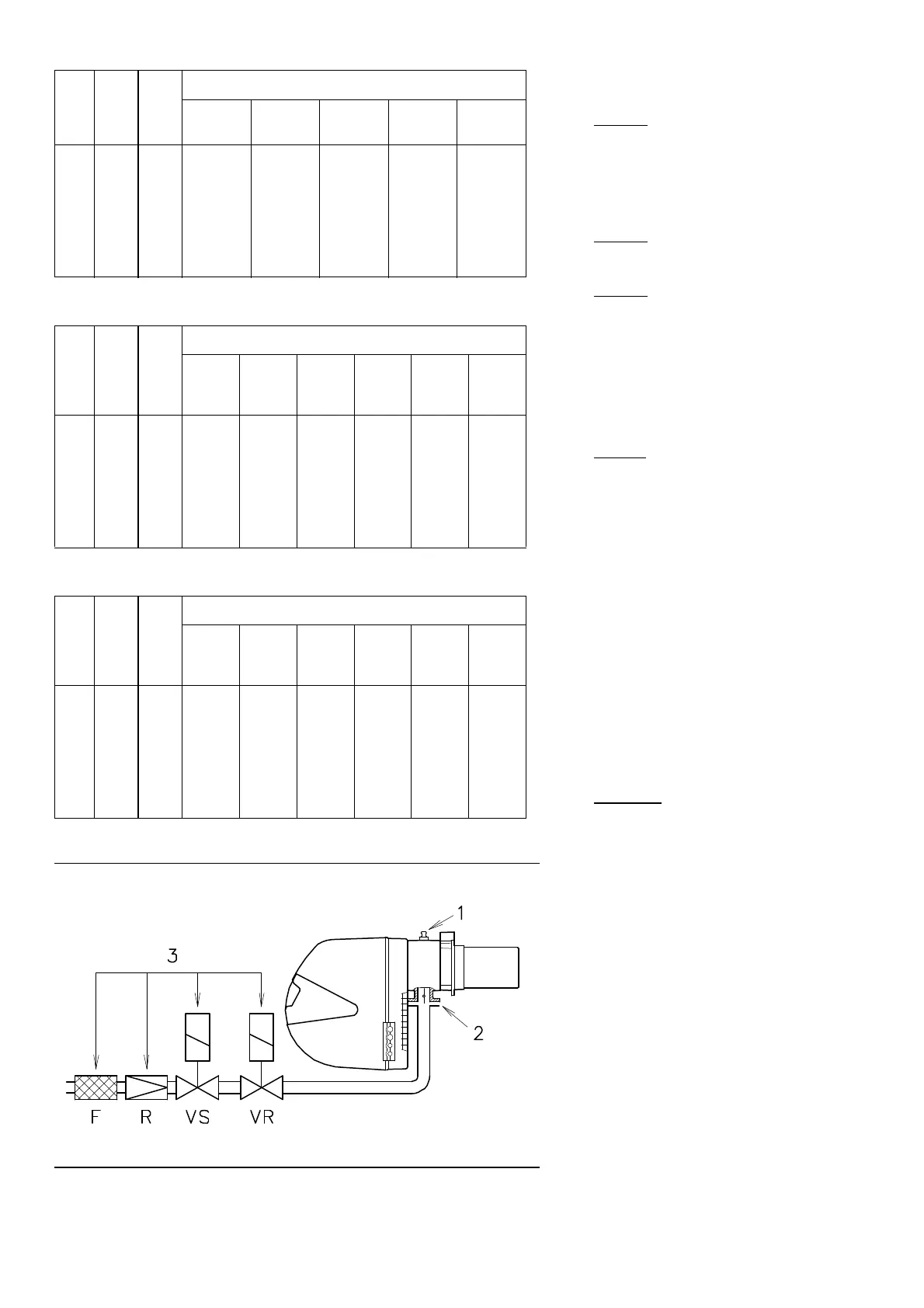

Column 1

Pressure loss at combustion head.

Gas pressure measured at test point 1)(B), with:

• Combustion chamber at 0 mbar

• Burner operating in 2nd stage

• Gas ring 2)(B)p.7 adjusted as indicated in dia-

gram (C)p. 7.

Column 2

Pressure loss at gas butterfly valve 2)(B) with

maximum opening: 90°.

Column 3

Pressure loss of gas train 3)(B) includes: adjust-

ment valve VR, safety valve VS (both fully

open), pressure governor R, filter F.

The values shown in the various tables refer to:

natural gas G20 PCI 10 kWh/Nm

3

(8.6 Mcal/Nm

3

).

With:

natural gas G25 PCI 8.6 kWh/Nm

3

(7.4 Mcal/Nm

3

)

multiply tabulated values by 1.3.

Calculate the approximate 2nd stage output of

the burner thus:

- subtract the combustion chamber pressure

from the gas pressure measured at test point

1)(B).

- Find the nearest pressure value to your result

in column 1 of the table for the burner in ques-

tion.

- Read off the corresponding output on the left.

Example - RS 28:

• 2nd stage operation

• Natural gas G20 PCI 10 kWh/Nm

3

• Gas ring 2)(B)p.7 adjusted as indicated in dia-

gram (C)p.7.

• Gas pressure at test point 1)(B) = 6 mbar

• Pressure in combustion chamber = 2 mbar

6 - 2 = 4 mbar

A 2nd stage output of 210 kW shown in Table RS

28 corresponds to 4 mbar pressure, column 1.

This value serves as a rough guide, the effective

delivery must be measured at the gas meter.

To calculate the required gas pressure at test

point 1)(B), set the output required from the

burner in 2nd stage operation:

- find the nearest output value in the table for

the burner in question.

- Read off the pressure at test point 1)(B) on

the right in column 1.

- Add this value to the estimated pressure in

the combustion chamber.

Example - RS 28:

• Required burner output in 2nd stage opera-

tion: 210 kW

• Natural gas G20 PCI 10 kWh/Nm

3

• Gas ring 2)(B)p.7 adjusted as diagram (C)p.7.

• Gas pressure at burner output of 210 kW,

taken from table RS 28, column 1 = 4 mbar

• Pressure in combustion chamber = 2 mbar

4 + 2 = 6 mbar

pressure required at test point 1)(B).

(A)

(B)

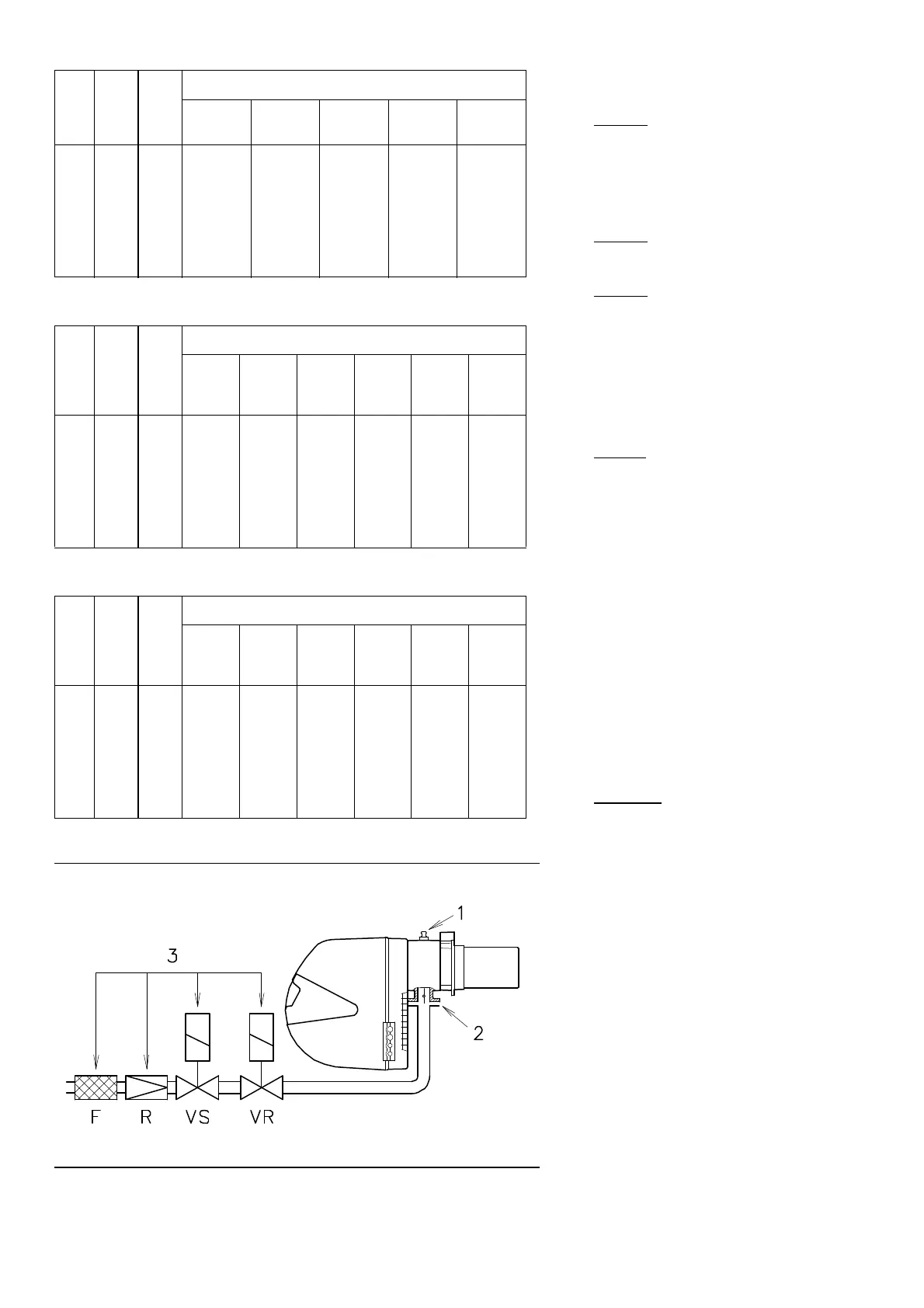

RS 28 ∆p (mbar)

RS 38 ∆p (mbar)

RS 50 ∆p (mbar)

kW 1 2

3

Ø

3/4

3970076

Ø 1”

3970077

Ø 1”

1/4

3970144

Ø 1”

1/2

3970145

Ø 1”

1/2

3970180

165

185

210

235

260

285

310

325

2,5

3,1

4,0

4,7

5,5

6,3

7,0

7,5

0,1

0,1

0,1

0,2

0,2

0,3

0,3

0,3

11,1

13,4

16,5

19,9

23,6

27,5

31,6

34,2

5,3

6,4

7,9

9,5

11,2

13,1

15,0

16,2

3,2

3,8

4,7

5,6

6,6

7,6

8,7

9,4

2,1

2,5

3,1

3,8

4,5

5,3

6,2

6,7

1,8

2,0

2,5

3,2

3,7

4,4

4,7

4,9

kW 1 2

3

Ø 1”

3970077

Ø 1”

1/4

3970144

Ø 1”

1/2

3970145

Ø 1”

1/2

3970180

Ø 2”

3970146

3970160

Ø 2”

3970181

3970182

230

260

290

320

350

380

410

440

2,6

3,1

3,7

4,3

4,8

5,4

6,0

6,6

0,2

0,2

0,3

0,3

0,4

0,4

0,5

0,6

9,2

11,2

13,4

15,8

18,3

20,9

23,7

26,6

5,4

6,6

7,9

9,2

10,6

12,1

13,7

15,3

3,6

4,5

5,5

6,5

7,6

8,8

10,1

11,4

3,0

3,7

4,4

4,8

5,9

6,6

7,0

8,1

1,4

1,7

2,1

2,5

3,0

3,5

4,0

4,5

1,8

2,2

2,7

3,3

3,5

4,0

4,4

5,0

kW 1 2

3

Ø 1”

3970077

Ø 1”

1/4

3970144

Ø 1”

1/2

3970145

Ø 1”

1/2

3970180

Ø 2”

3970146

3970160

Ø 2”

3970181

3970182

290

330

370

410

450

490

530

580

2,2

2,9

3,6

4,3

5,0

5,6

6,3

7,2

0,3

0,4

0,5

0,6

0,7

0,9

1,0

1,2

13,4

16,6

20,0

23,7

27,6

31,7

36,1

41,8

7,9

9,7

11,6

13,7

15,9

18,2

20,6

23,9

5,5

6,9

8,4

10,1

11,9

13,7

15,7

18,5

4,4

5,0

6,1

7,0

8,3

9,7

10,5

12,0

2,1

2,7

3,3

4,0

4,7

5,5

6,3

7,4

2,7

3,4

3,9

4,4

5,1

5,9

6,6

7,8

D934

Loading...

Loading...