23

20135920

Start-up, calibration and operation of the burner

7.1 Notes on safety for the first start-up

7.2 Combustion adjustment

In conformity with EN 267, the installation of the burner on the

boiler, the adjustment and testing must be carried out in compli-

ance with the instruction manual of the boiler, including control of

the CO and CO

2

concentration in the flue gases, their tempera-

ture and the average temperature of the water in the boiler.

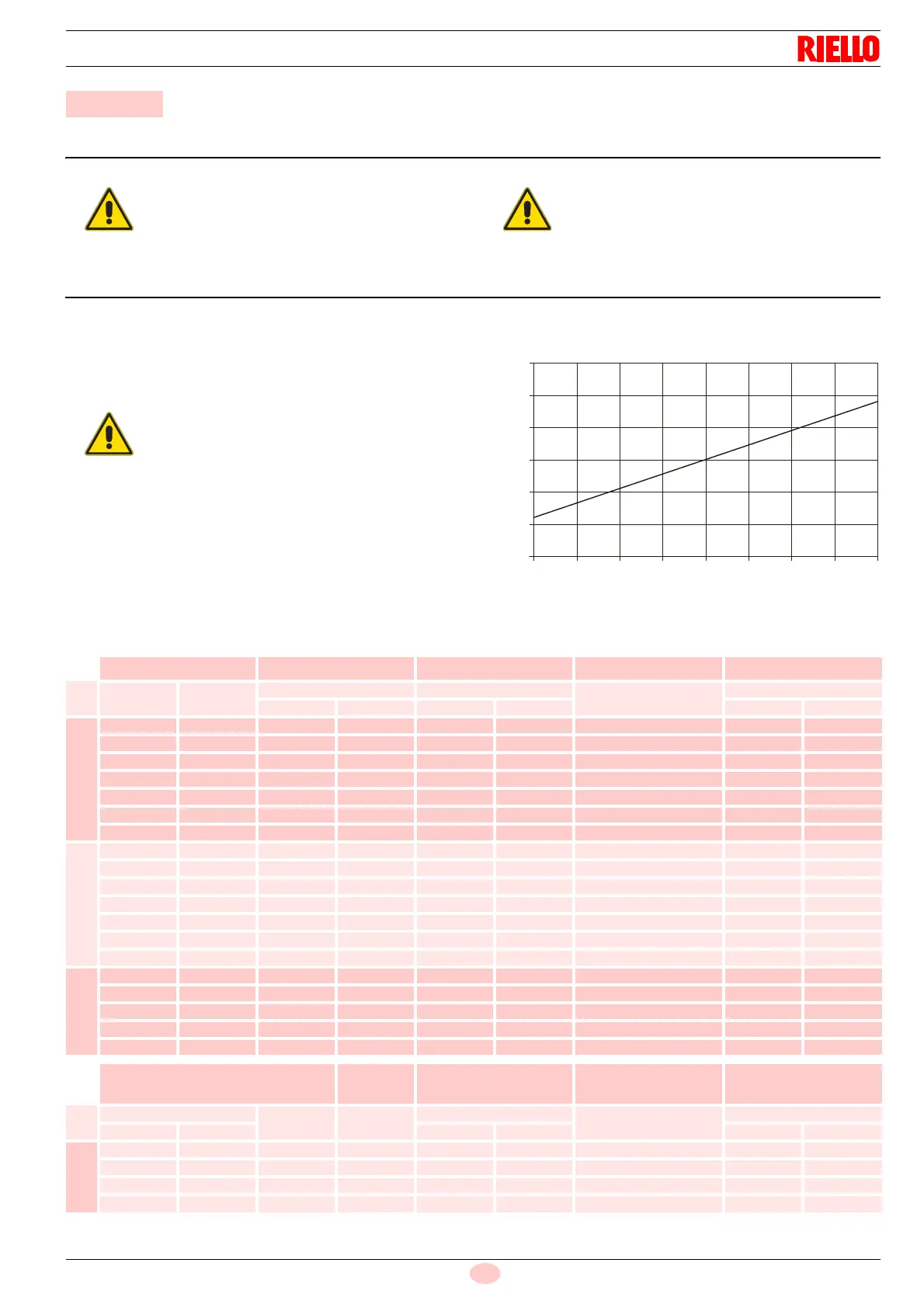

To suit the required boiler output, choose the proper nozzle and

adjust the pump pressure and the air damper opening in accord-

ance with the following data. The values in Tab. I are obtained on

the boiler (according to EN267).

They refer to 12.5 % CO

2

, at sea level and with an ambient and

light oil temperature of 20 °C.

Tab. I

7 Start-up, calibration and operation of the burner

The first start-up of the burner must be carried out

by qualified personnel, as indicated in this manual

and in compliance with the standards and regula-

tions of the laws in force.

Check the correct working of the adjustment, com-

mand and safety devices.

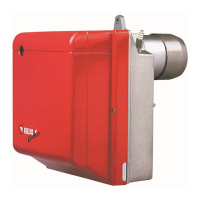

The temperature of the combustion air (relative to

the place where the burner is installed) may vary

during the season, it influences the CO

2

of the

burner. We recommend adjusting the CO

2

based

upon the temperature of the combustion air at the

time when the burner calibration is carried out in

accordance with what is shown in the following di-

agram.

Example Combustion air temperature =10°C ad-

just the CO

2

to 12.5%.

Fig. 22

Combustion air temperature

D4604

14.5

14.0

13.5

13.0

12.5

12.0

11.5

0 5 10 15 30

40

352520

% CO

2

Nozzle Pump pressure Burner output Adjust. comb. head Adjusting damper

GHP Angle

bar kg/h ± 4%

Set-point

Set-point

1st stage 2nd stage 1st stage 2nd stage 1st stage 2nd stage

380T1

1.00 60° 9 14 3.5 4.3 0 0.2 1.5

1.10 60° 9 14 3.8 4.8 1 0.4 2.1

1.25 60° 9 14 4.3 5.4 2 0.6 2.6

1.50 60° 9 14 5.2 6.5 3 0.8 3.4

1.75 60° 9 14 6.1 7.6 4 1.2 4.8

2.00 60° 9 14 7.0 8.7 5 1.4 5.4

2.25 60° 9 14 7.8 9.8 6 1.6 6.0

394T1

1.50 60° 9 15 5.3 6.8 0 0.2 0.5

1.75 60° 9 15 6.4 8.2 0.5 0.25 1.0

2.00 60° 9 15 7.2 9.3 1.5 0.4 1.1

2.25 60° 9 15 8.2 10.5 2.5 0.5 1.5

2.50 60° 9 15 8.7 11.2 3.5 0.6 2.0

3.00 60° 9 15 10.5 13.5 5.0 0.8 3.0

3.50 60° 9 14 12.5 15.2 6.0 1.0 3.9

397T1

2.50 60° 9 14 8.7 10.8 0 0.2 1.8

3.00 60° 9 14 10.4 13.0 1 0.5 2.7

3.50 60° 9 14 12.2 15.2 2.5 0.8 3.7

4.00 60° 9 14 13.9 17.3 4 1.0 4.5

4.50 60° 9 14 15.6 19.5 6 1.3 6.0

Nozzle

Pump

pressure

Burner output Adjust. comb. head Adjusting damper

GHP

Angle bar

kg/h ± 4%

Set-point

Set-point

1st stage 2nd stage 1st stage 2nd stage 1st stage 2nd stage

398T1

2.00 1.00 60° 12 8.0 12.4 0 0.25 2.1

2.00 2.00 60° 12 8.0 16.4 3 0.15 3.0

2.50 2.50 60° 12 10.3 20.5 6 0.3 4.4

3.00 3.00 60° 12.5 12.6 25.0 8 0.6 6.0

Loading...

Loading...