Linear installation guide 13563-B 02-19 | 35

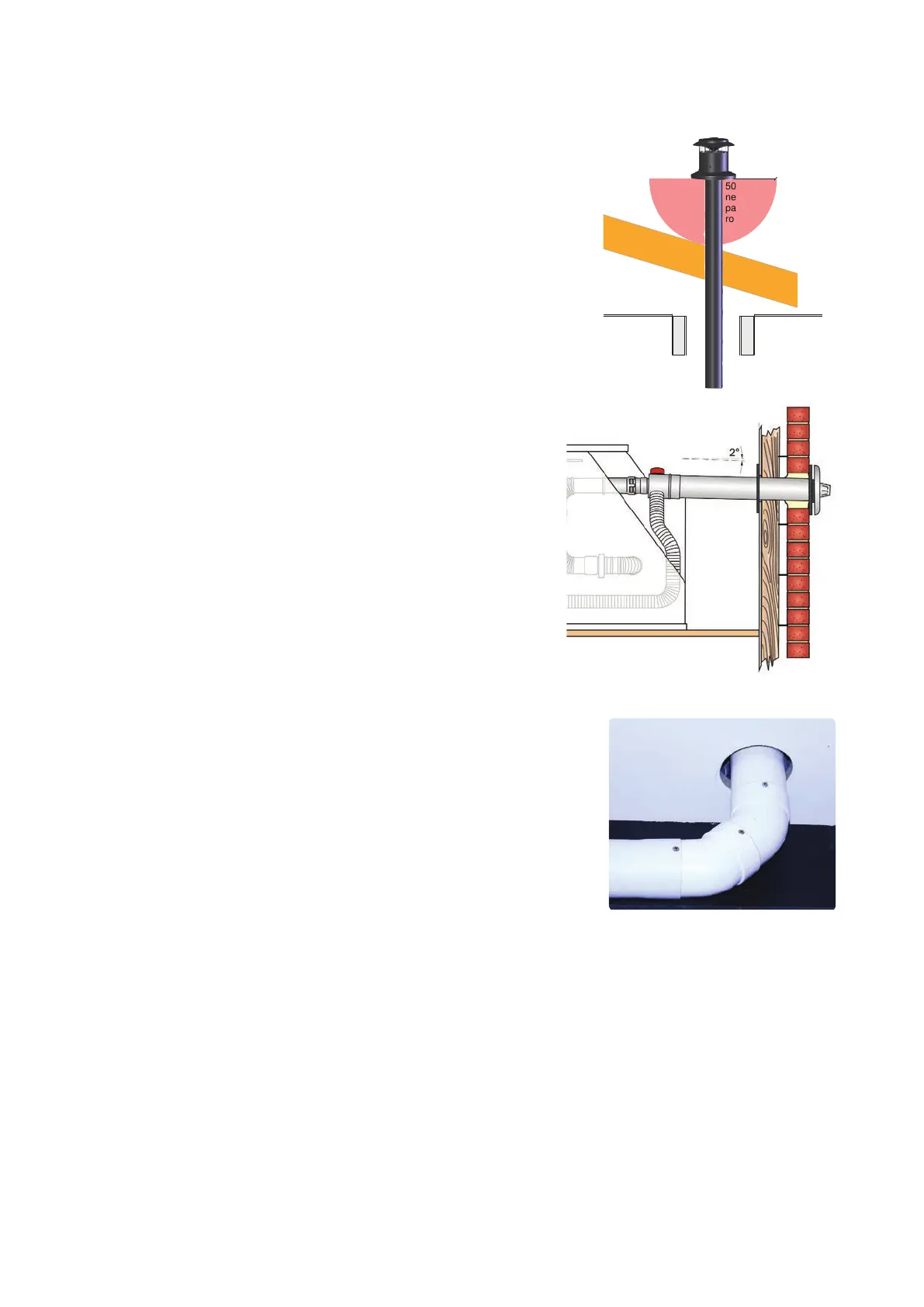

Vertical ue cowl clearance

To ensure products of combustion are cleared, adequate clearance

from the building is required. The vertical ue cowl should have a

500 mm clearance from any part of the building. This also applies

to steeped and pitched roofs, where the ue cowl should be 500

mm clear of the ridge line. An adequate ow of fresh air must exist

around the ue cowl following installation.

Minimum clearances are shown in AS/NZS 5601.1.

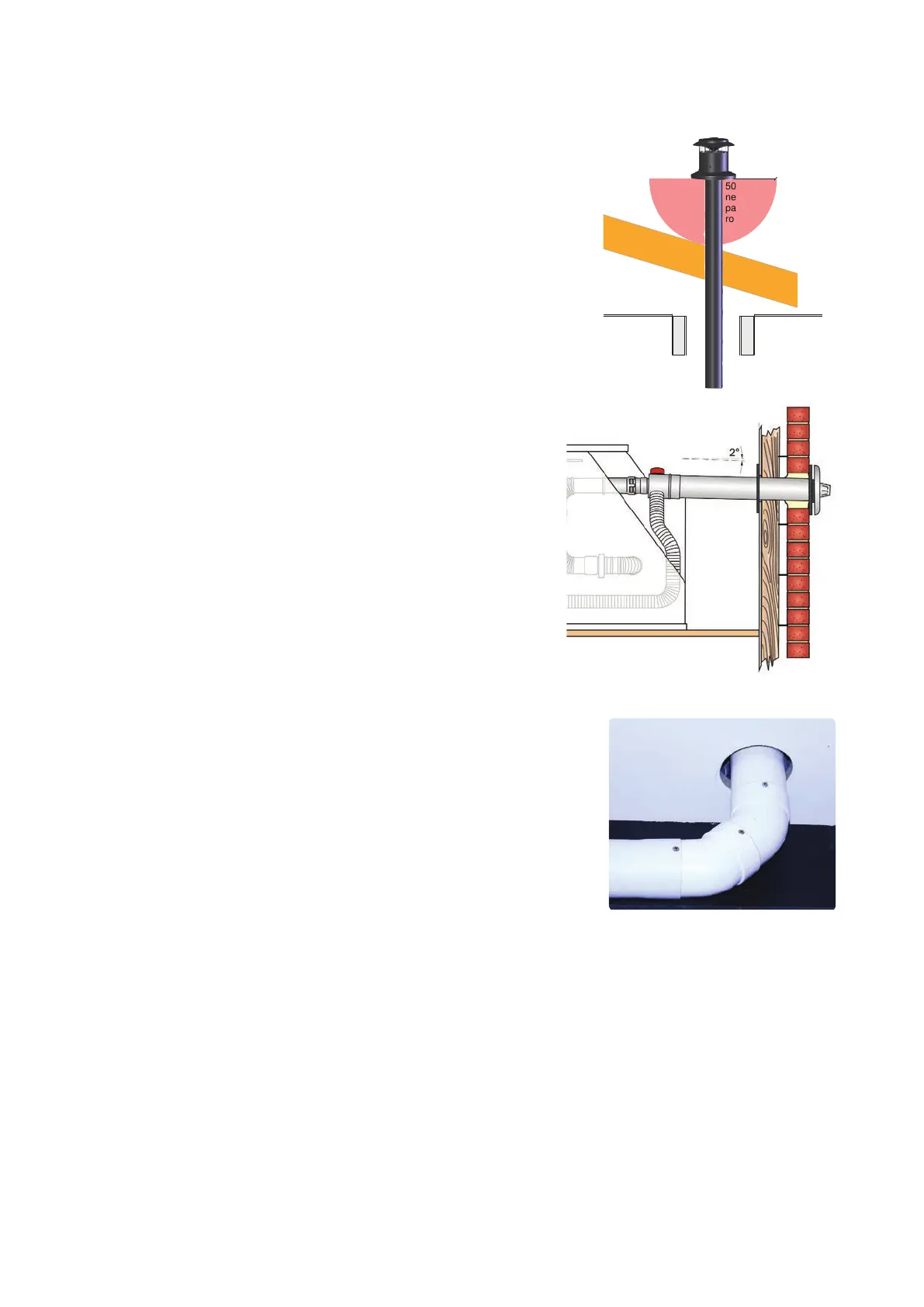

2° fall to the horizontal wall terminal

For direct sideways, back, forward, up-and-over, and down-

and-out ue installations, there MUST BE a continuous fall

of at least 2° to the horizontal wall termination point to drain

condensate.

ESBEND installation and connection

If installed incorrectly there is potential for the outer bend to

overheat. A separate installation sheet is provided with each

ESBEND kit to ensure correct alignment of the bend component.

Flue sections located outside

Sections of the ue located outside require the following precautions:

• Only use PVC cement between the joints of the outer PVC pipes to secure and seal the joints

against ingress of dust and water.

• Only use non-acidic silicone sealant between the joints of the outer PVC pipe and any mating

aluminium components to secure and seal these joints against ingress of dust and water.

Silicone containing acetic acid or other acids as the curing agent may cause the aluminium to

corrode.

500 mm to

nearest

part of the

roof

ESBEND and flue pipe connection

Loading...

Loading...