36 | Linear installation guide 13563-B 02-19

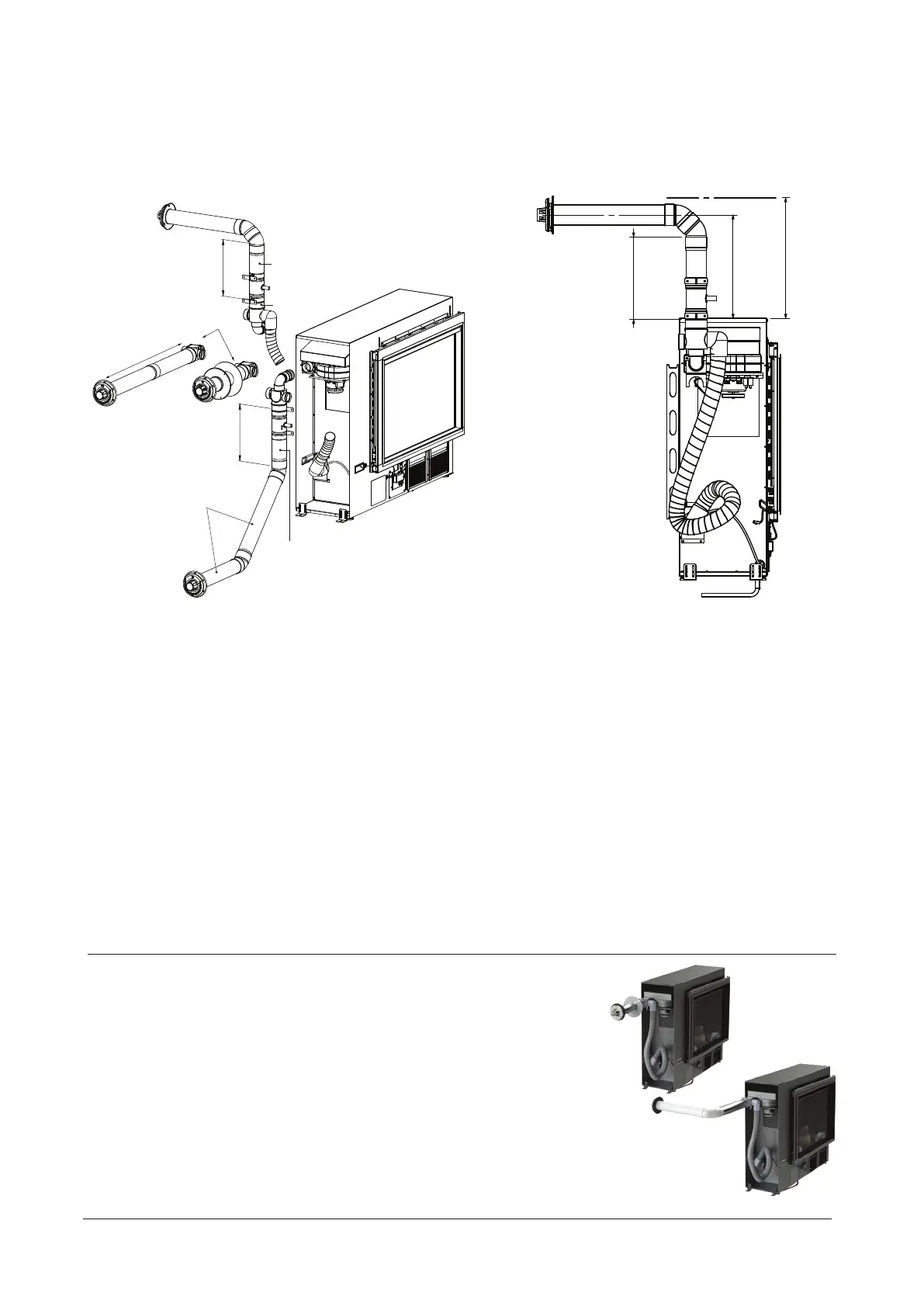

Flueing options

The gas pressures of the Linear are factory set for short ue installations, as pictured below. All

other installations, greater than 3 m in length, are long ue installations and will require a dip switch

change, refer commissioning sheet.

300 mm min.

300 mm min.

ESWTERM

ESPIPE900

(cut down)

EVOKIT03

u

p

to 3 m

ASPDFK

ESWTERM

45 ° bends

ESPIPE900

(cut down)

ESPIPE900

Maximum ue length and number of bends

• Maximum ue length = 8.5 m

• Maximum number of 90 ° bends = three

For every 90 ° bend, the overall length must be reduced by 1 m. For example, if an installation has

three 90 ° bends, the maximum ue length can be 5.5 m.

The Linear ue installation differs to Arriva and Evolve power ue installations as the elbow

component of the Adaption ue (EVOKIT03) is not counted a 90 ° bend.

300 mm of straight ue before any bends

300 mm minimum of straight ue is required before any bends. This is required due to heat

produced from the initial section of the ue.

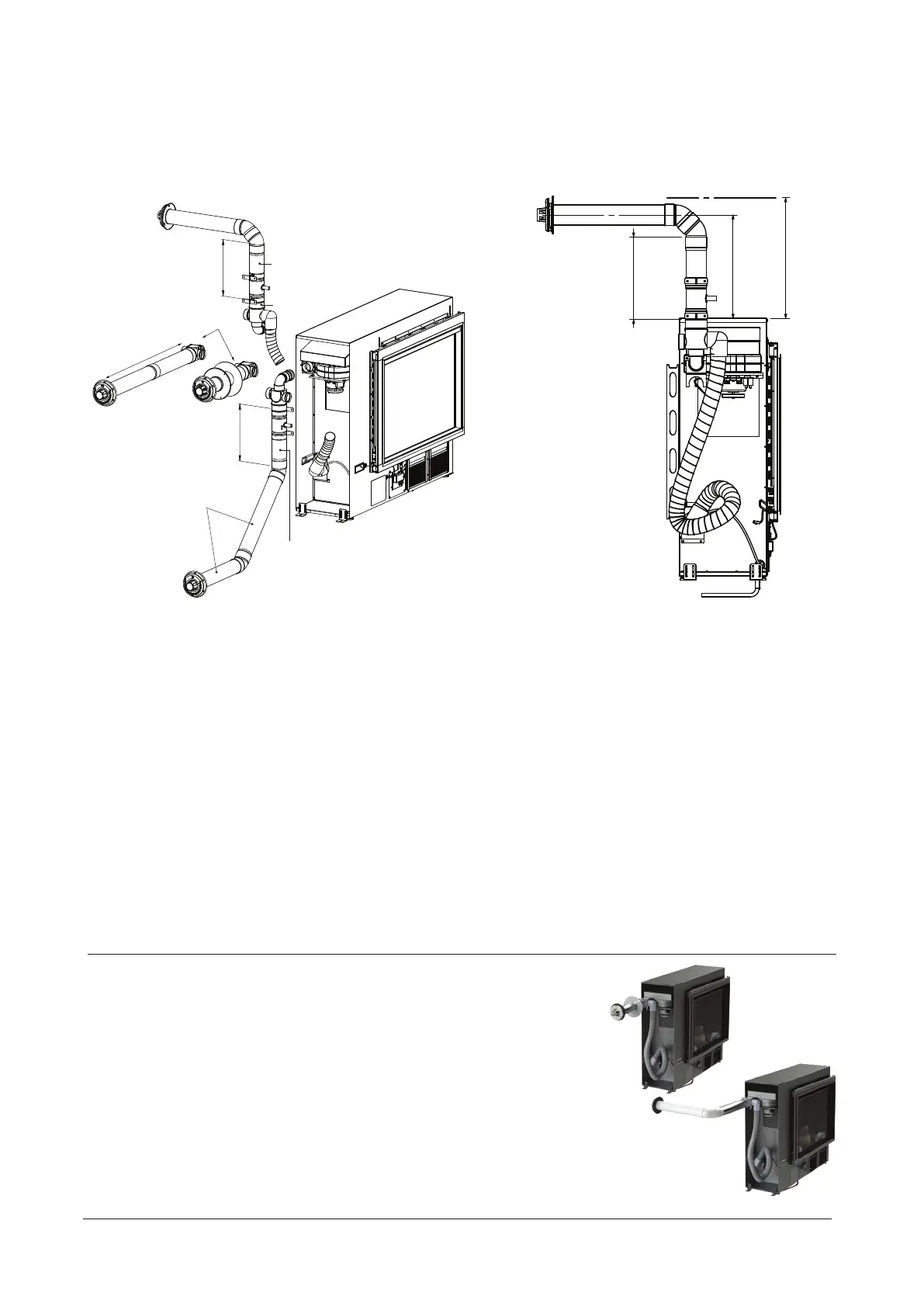

Side direct, side extended, side and back ueing

Side direct through-the-wall ueing for walls up to 385 mm thick.

Flue can be extended if the wall thickness is greater than 385 mm

by using additional lengths of ue pipe, and ue can be directed

behind using the bend kit. Refer to p. 38 for more information.

Flue components used:

• Direct ue kit (ASPDFK)

1

• Flue pipes (ESPIPE900)

• 45 ° bends (ESBEND) to change direction

1

Flue terminal section is reusable when making the ue longer.

~380 mm

300 mm min.

(top of adaptor

to first bend)

445 mm

(to clear flue)

For lowest cost, optimal performance, ease of installation and servicing, Rinnai recommend short

ue installations are considered before all other options.

Loading...

Loading...