4 x Set-up and installation

ROTEX GCU compact -

19

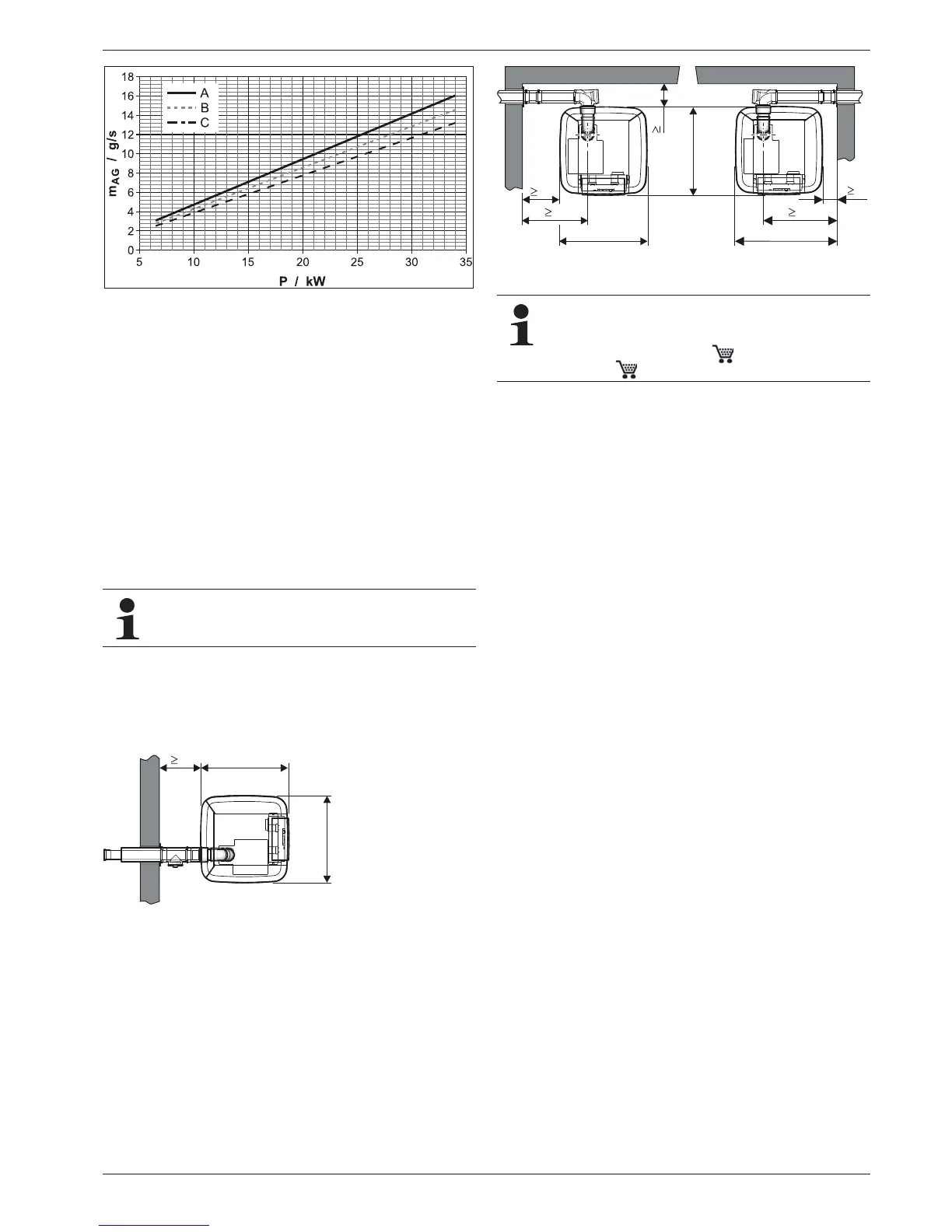

The flue gas mass flow of the plant depends on the burner output

of the ROTEX GCU compact.

4.5.2 Connecting a flue gas line

Requirements

– The flue system fulfils the requirements described in

section 4.5.1.

– The flue system fulfils any other required national or regional

safety requirements.

– The ROTEX GCU compact is installed correctly.

Connection

Ɣ Connect the ROTEX GCU compact to the flue gas system

inside the installation room (fig. 4-1 / fig. 4-2).

For dimensions, see tab. 4-1.

Ɣ Place the nameplate of the flue gas pipe in the installation

room.

a

A Natural gas E/H (G20)

B Natural gas LL/L (G25)

C Liquid gas

m

ET

Flue gas mass flow

P Burner load

Fig. 4-

12 Flue gas mass flow in dependence of the burner load ROTEX

GCU compact (all types)

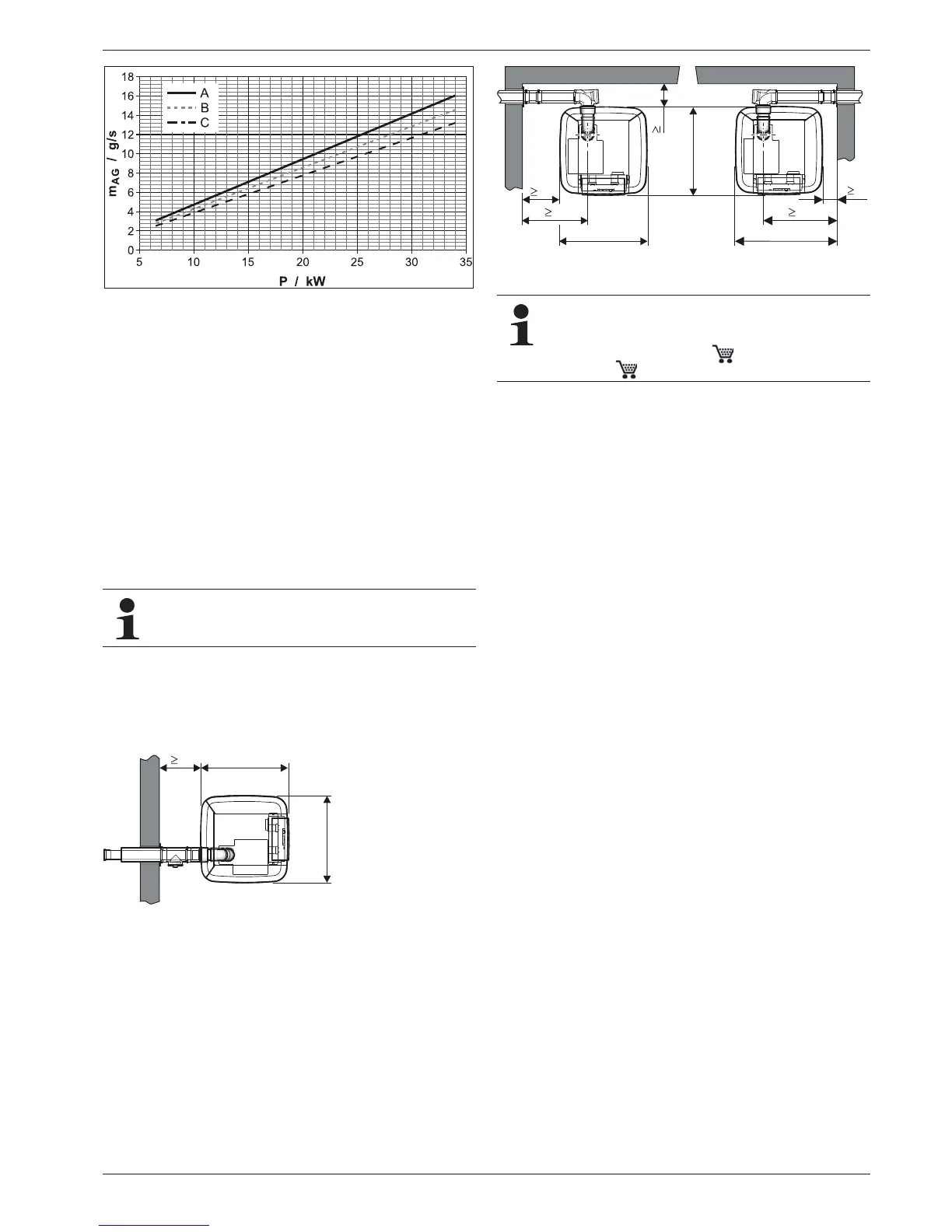

We recommend to use the associated ROTEX LAS-

sets (see fig. 4-15). They satisfy all requirements and

are also fitted with special acid-proof seals.

Fig. 4-13 Plan view GCU compact Flue gas connection to the rear with

SET H (see section 4.5.3) - (for dimensions, see tab. 4-1)

Fig. 4-14 Plan view GCU compact Flue gas connection to the side with

SET

K (see section 4.5.3) - (for dimensions, see tab. 4-1)

In some cases, the resonance in the flue system can

amplify the noise at the mouth of the flue gas pipe. The

noise level can be effectively reduced with the applica-

tion of a silencer (E8 MSD, 15 45 78 bzw.

E11 MSD, 15 45 79).

Loading...

Loading...