10 x Faults and malfunctions

ROTEX GCU compact -

51

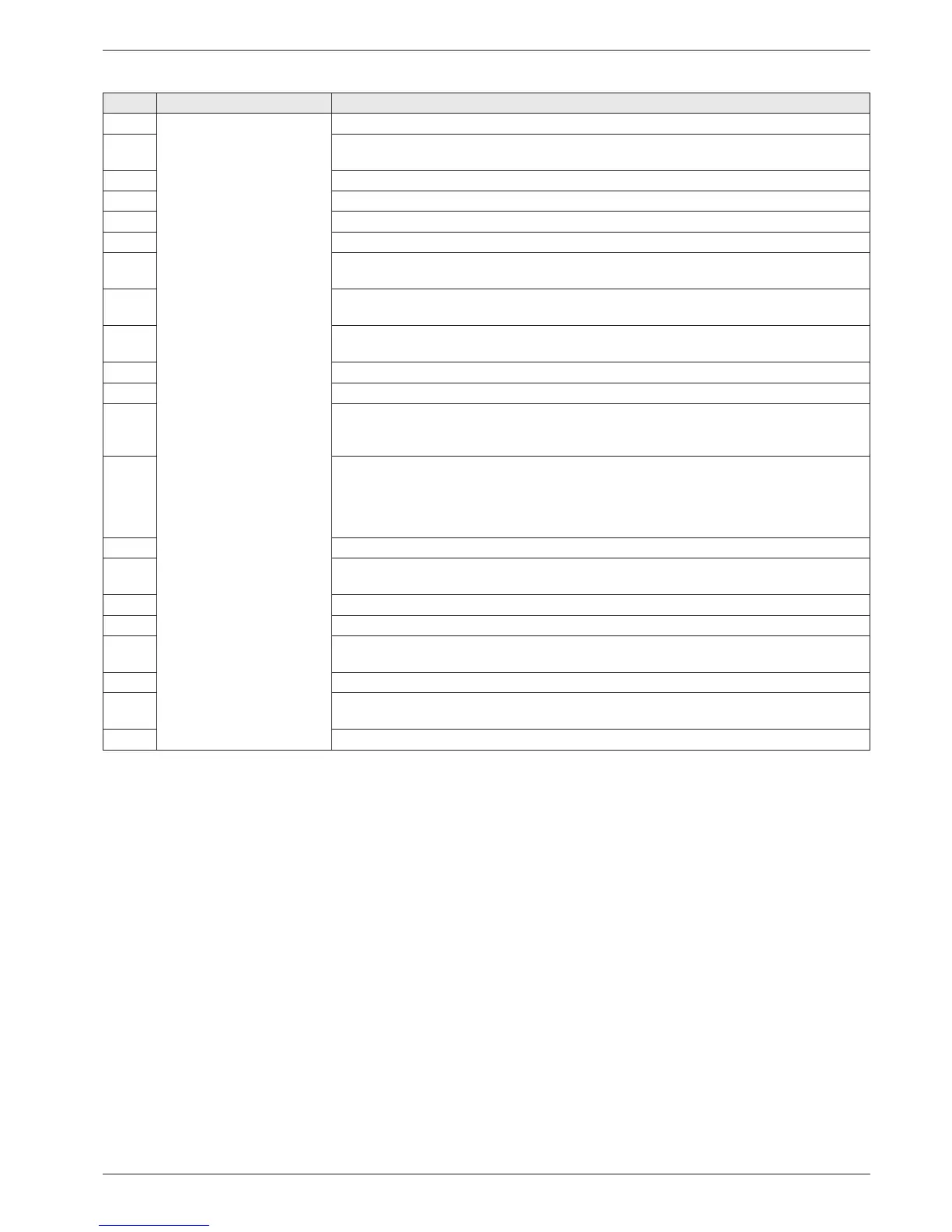

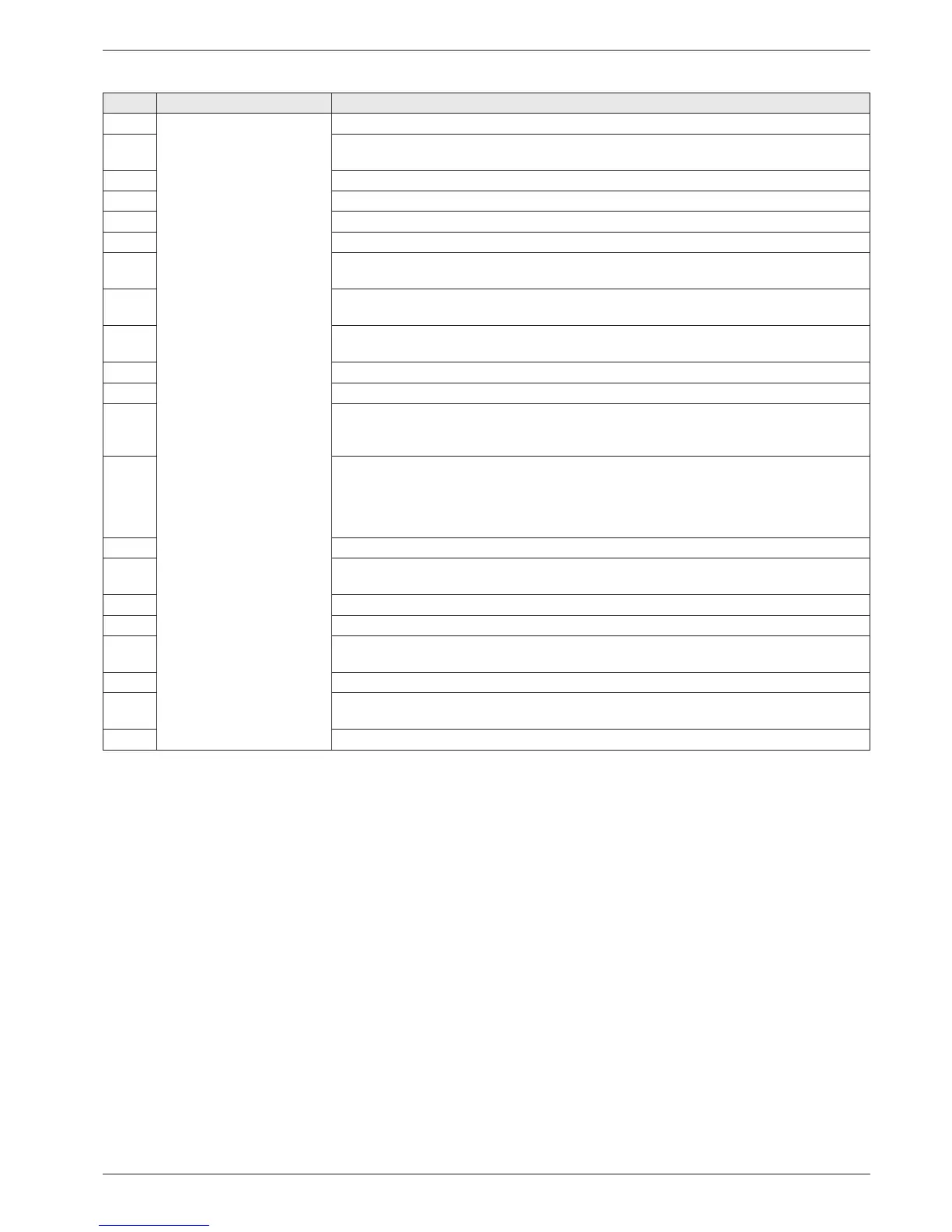

10.3 Fault codes

Tab. 10-2 Error codes of interlocking malfunctions (can be detected by

the firing unit)

Code Component/Designation Fault

E12

Automatic firing unit

Interlocking fault

t

V

or t

R

defective (cable break, short circuit).

E65

During calibration, difference from prior value was too high (unclean supply air, electrode re-

placement, electrode defective).

E129 Flow temperature exceeds limiter temperature (overtempera

ture

, no heat dissipation)

E130 Return flow temperature exceeds limiter temperature (overtemperature, n

o heat dissipation)

E132 2x no flame formation at end of safety time (no gas, valves do not open, n

o ignition sparks)

E138 2x flame failure at end of safety time (ionisation electrode defective or dirty)

E148

Gas valve test negative. A flame is sti

ll detected 15 s after the burn

er shutdown (gas valve

jams).

E152

Speed not reached during pre- and post-ventilation (burner blower defective, power supply

to blower, electronics fault in the blower, cable break).

E154

Blower stationary position not reached (burner blow

er defective, electronic fault in

the burner

blower).

E158 EEPROM fault (manufacturer’s parameters).

E159 EEPROM fault (safety parameters).

E189

Regulation deviation during ionisation process too high (as of 2nd fault) (bur

ner grounded in-

correctly or faulty supply voltage firing unit, gas flow pressure too low, ionisation electrode

bent or oxidised, ionisation track faulty, safety gas control block defective)

E190

– Impermissible gas fitting initiation within 10 s (from the 2nd fault) or

– Blower falls below 80 % of the minimum speed within 10 s (from the 2nd fault).

(Burner blower defective, wrong gas type set, missing/incorrect gas nozzle, safety gas con-

trol block defective, gas flow pressure too low)

E191 Internal electrical fault- from the 2nd fault (switch the unit on/off).

E192

A value fell beneath the minimum thresholds during calibration (flue gas recirculation, elec-

trodes oxidised, ionisation track faulty, poo

r earthing, transition resistances).

E194 Interruption during calibration (no heat dissipation, minimum calibration

time not met).

E195 Impermissible internal value (electronic fault).

E202

A value exceeded the maximum threshold values during calibration (unclean supply air, basis

value too high).

E215 EEPROM fault (elec

tronic fault).

E226

Fault found in the flame amplifier evaluation during the idle state check (electronic fault,

short

circuit ionisation electrode or cable).

E227 Internal fault to firing unit.

Loading...

Loading...