32

ROTEX GCU compact -

5 x Start-up

6. In the programme [Emission Measurement] select the setting

[Base Load] (see chapter 15.2), but do not confirm.

– Make sure the heat can dissipate into the heating network

during emission meas

urement.

Ɣ Use the flue gas analyser to check the burner settings and

compare them with tab. 5-1 to tab. 5-3.

a) If the O

2

/CO

2

concentrations lie within the permissible

values:

Î No additional measures are required.

b) If the O

2

/CO

2

concentrations lie outside the permissible

values:

Î Carry out 100% calibration and adjust the [Drop Io-base]

in such a way that the setting range is reached (see

chapter 7.3.4) and repeat the measurement from step 5.

Ɣ Document the measured

values in the "Installation certifi-

cation" and in the operating manual.

7. End programme [Emission Measurement].

8. Set manual mode from the RoCon BF control (see operating

instructions "RoCon BF Control").

9. Check the resistance in the flue gas line (see chapter 4.5).

5.1.4 After start-up

Ɣ Mount the sound insulation hood (see chapter 4.4.3).

Ɣ Check all items on the "Checklist after start-up" (see

section 5.2).

Ɣ Log the test results on the checklist

.

Only when it is possible to answer all items on the checklist

with Yes, i

s it allowed to hand over the ROTEX GCU compact

to the operator.

CAUTION!

The firing unit is programmed to take into

account the ageing of th

e components.

A 100 % calibration of the firing unit can have

a negative impact on th

e above even if the

exhaust setting values (tab. 5-1 to tab. 5-3) are

adhered to.

Ɣ Only carry out a calib

ration of the firing unit

when the exhaust setting values are not

adhered to, or when a mechanical change

was carried out, e.g. by replacing the

component with original ROTEX spare

parts.

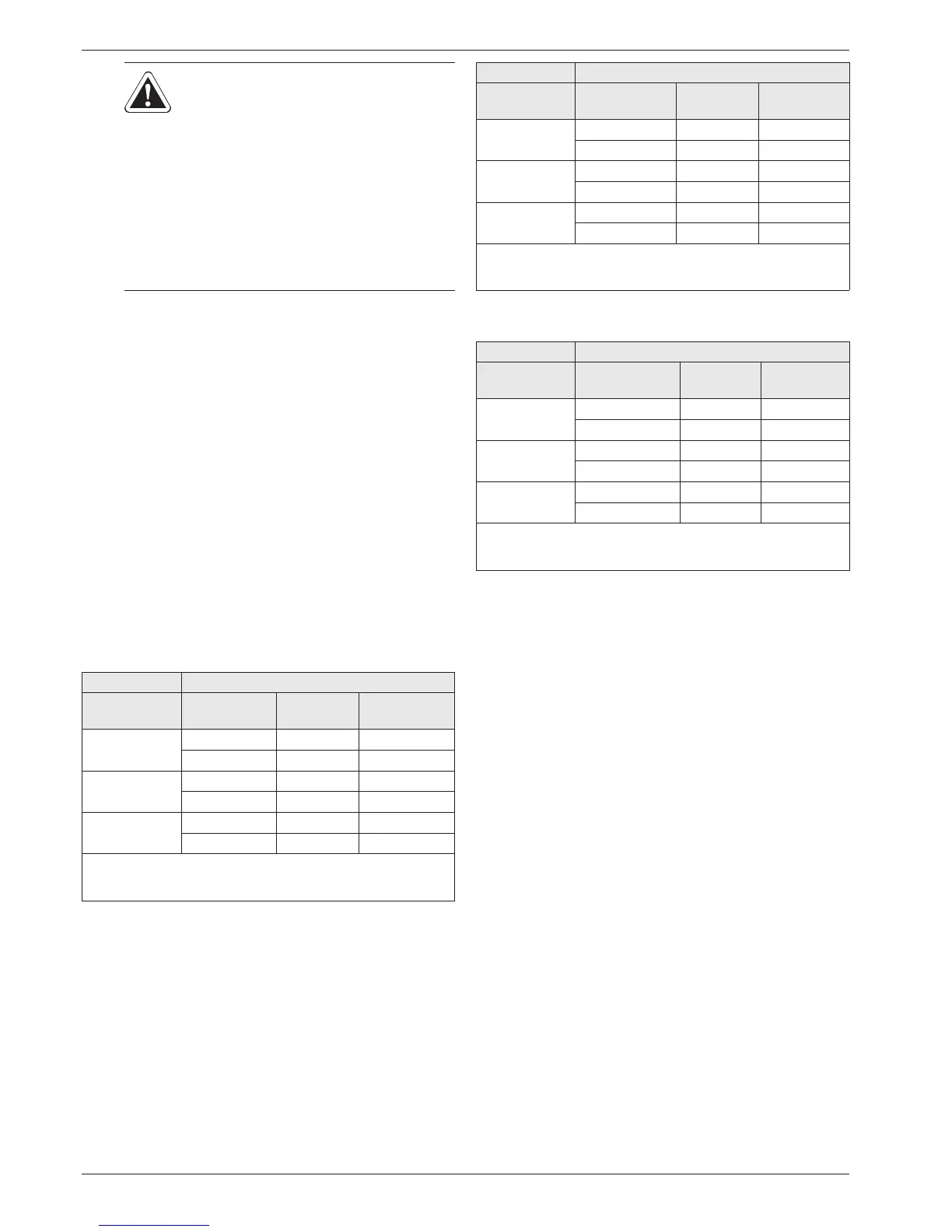

Type GCU compact 315 / 515 (BIV)

Gas type

(Prüfgas)**

Burner load O

2

-content

in %

CO

2

-content

in %

Natural gas E/H

(G20)

Base Load 4.0 - 5.5 8.6 - 9.5

Full Load 4.0 - 5.4 8.7 - 9.5

Natural gas

LL

/L (G25)

Base Load 4.0 - 5.5 8.5 -

9.3

Full Load 4.0 - 5.4 8.5 - 9.3

Propane*

(G

31)

Base Load 4.0 - 5.5 10.0 -

11.2

Full Load 4.0 - 5.4 10.2 - 11.2

* Liquid gas setting

** Compare with the information on the yellow sticker attached to the burner

housing

Tab. 5-1 Start-up control values for GCU compact 315 and GCU

compact 515 for various gas types

Type GCU compact 324/ 524 (BIV)

Gas type (test

gas)**

Burner load O

2

-content

in %

CO

2

-content

in %

Natural gas E/H

(G20)

Base Load 4.0 - 5.5 8.6 - 9.5

Full Load 3.8 - 5.1 9.0 - 9.6

Natural gas

LL/L (G2

5)

Base Load 4.0 - 5.5 8.5 - 9.3

Full Load 3.8 - 5.1 8.7 - 9.4

Propane*

(G31)

Base Load 4.0 - 5.5 10.0 - 11.2

Full Load 3.8 - 5.1 10.4 - 11.3

* Liquid gas setting

** Compare with the information on the yellow sticker attached to the burner

housing

Tab. 5-2 Start-up control values for GCU compact 324 and GCU

compact 524 for various gas types

Type GCU compact 533 (BIV)

Gas type (test

gas)**

Burner load O

2

-content

in %

CO

2

-content

in %

Natural gas E/H

(G20)

Base Load 4.0 - 5.5 8.6 - 9.5

Full Load 3.5 - 4.9 9.0 - 9.8

Natural gas

LL

/L (G2

5)

Base Load 4.0 - 5.5 8.5 - 9.3

Full Load 3.5 - 4.9 8.8 - 9.5

Propane*

(G31)

Base Load 4.0 - 5.5 10.0 - 11.2

Full Load 3.5 - 4.9 10.5 - 11.4

* Liquid gas setting

** Compare with the information on the yellow sticker attached to the burner

housing

Tab. 5-3 Start-up control values for GCU compact 533 for various gas

types

Loading...

Loading...