10 x Faults and malfunctions

ROTEX GCU compact -

53

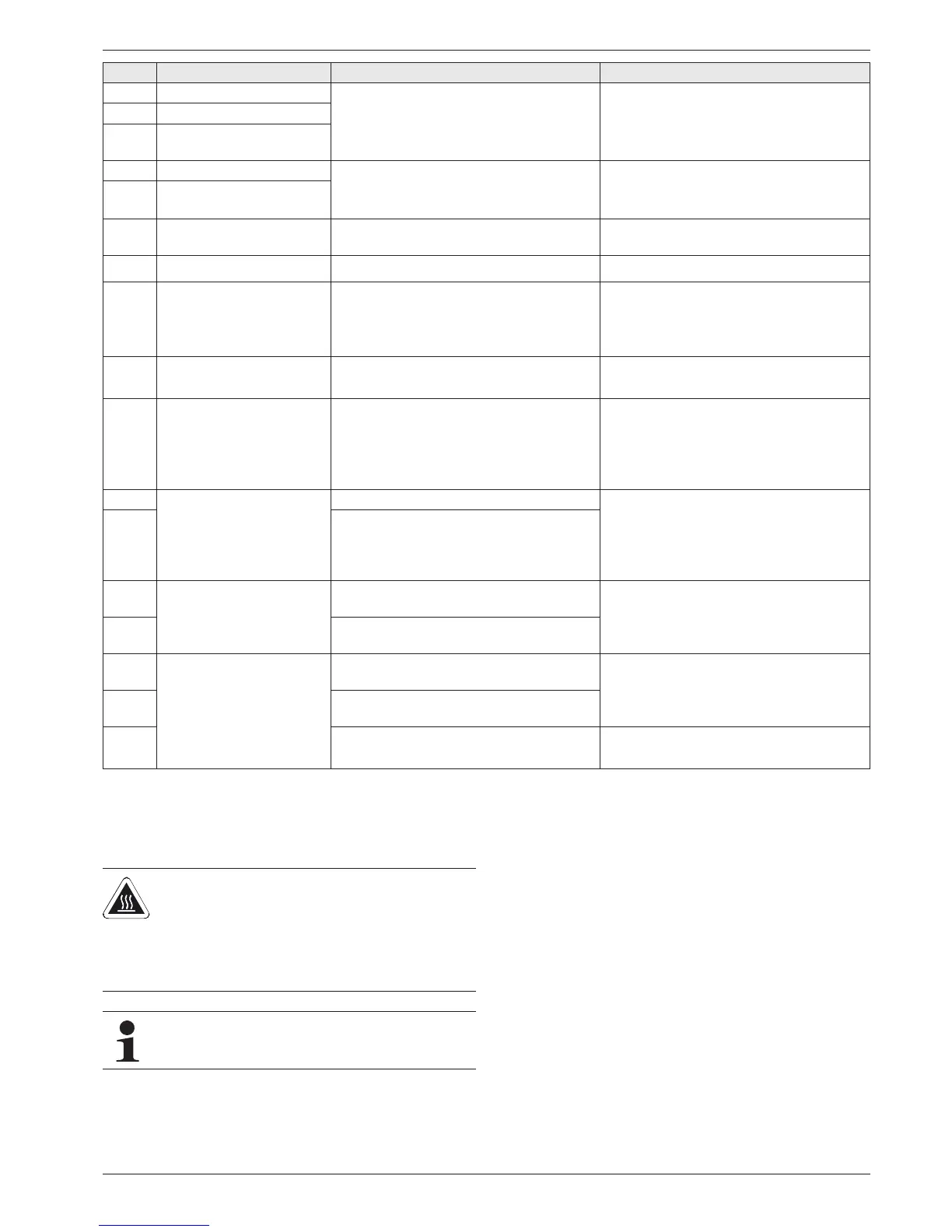

Tab. 10-4 Fault codes (can be detected by switching panel PCB)

10.4 Rectifying burner faults and STB faults

Interlocking faults detected by the automatic firing unit can only

be reset manually directly on the boiler.

Unlocking the automatic firing unit:

Requirements: The cause of the malfunction is rectified, the

burner is electrically connected.

1. Switching ROTEX GCU compact on.

2. Push the Exit button (fig. 6-1, item 15) for at least 5 secs.

Î Menu "Special Level" is displayed.

3. Select the "FA failure" level w

ith the rotary switch.

Î Fault code and request "Reset" is displayed.

4. Select "Yes" with the rotary switch.

5. Confirm the changes with a brief push of the rotary switch.

Î Fault is reset.

6. Cancelling and jump back by pushing the Exit button again.

Code Component/Designation Fault Possible fault rectification

E72 Internal mixer sensor

Measured value outside measuring range,

temperatu

re sensor defective.

Ɣ Check cable, terminal and plug connec-

tions.

Ɣ Replace the temperature sensor

.

E75 Outside temperature sensor

E76

Storage

tank temperature

senso

r

E81 Eeprom

Internal fault

Ɣ Total reset

Ɣ Replace switching panel PCB in

controller.

E88

Switching panel

PCB control-

ler

E91 Connected CAN modules

Bus detection of a CAN module doubly pre-

sent.

Ɣ Set bus addresses

correctly.

E100 Flue gas temperature Internal fault Ɣ Replace the combustion controller.

E129 Pressure sensor

Measured value outside measuring range,

sensor / temperature sensor defective.

Ɣ Check cable, terminal and plug connec-

tions.

Ɣ Replace the sensor / temperature

sensor.

E198 FlowSensor Volume flow too low.

Ɣ Check heating circulation pump / filter /

heating network.

E200

Communi

cation automatic

firing

Fault in communication between automatic fir-

ing and switching panel PCB on controller.

Ɣ Che

ck cable and plug connections.

Ɣ Total reset

Ɣ Replace control panel PCB on the Gas

Combi Unit compac

t.

Ɣ Replace the combustion controller.

W8001

FlowSensor

Volume flow fell below the minimum limit.

Ɣ Check the parameter settings (see

Control System Instructions).

Ɣ Check the pipes and valves for

blockages.

Ɣ Che

ck the built-in circulation pump.

E8002 Flow

under minimum threshold (300 l/h)

W8003

Flue gas temperature

The flue gas temperature has exceeded the

threshold temperature.

Ɣ Cle

an the boiler

E8004

The flue

gas temperature has exceeded the

pe

rmissibl

e absolute maximum value.

E8005

Water pressure

Measured value under permissible minimum

value.

Ɣ Top up heating water.

Ɣ

Leak test

W8006

Warning message: Maximum permissible

p

ressure drop exceeded

.

W8007

Warning message: Measured value over per-

missible maximum value.

Ɣ Che

ck diaphragm expansion vessel.

Ɣ Drain heating water.

WARNING!

Risk of burns due to very hot boiler body with STB

fault.

Ɣ Do not touch any metallic parts on the boiler.

Ɣ Let the boiler cool down.

Ɣ Wear protective gloves.

The cause of the last fault is saved in the unit and can

be reconstructed on restarting the unit, even after

power failure.

Loading...

Loading...