6 Preparation

Installer reference guide

16

RVLQ05+08CAV4 + RHYHBH05AA + RHYHBH/X08AA +

RHYKOMB33AA

ROTEX HPU hybrid

4P355635-1 – 2013.05

6.2.2 Refrigerant piping requirements

▪ Use piping with annealed temper grade, in function of the pipe

diameter.

▪ The minimal pipe thickness should comply with applicable

legislation. The minimal pipe thickness for R410A piping must be

in accordance with the following table.

Pipe for… Outer diameter

(Ø)

Pipe thickness

(t)

Liquid 6.4 mm (1/4") ≥0.8 mm

t

Ø

Gas 15.9 mm (5/8") ≥1.0 mm

6.3 Preparing water piping

6.3.1 Water circuit requirements

▪ Use the indoor unit ONLY in a closed water system.

Using the system in an open water system will lead to excessive

corrosion.

▪ The maximum water pressure is 3 bar.

Provide adequate safeguards in the water circuit to ensure that

the maximum pressure is NOT exceeded.

▪ In case heat pump convectors are connected, the temperature of

the water in the convectors should NOT exceed 65°C. If

necessary, install a thermostatic controlled valve.

▪ In case underfloor heating loops are connected, install a mixing

station to prevent water that is too hot from entering the underfloor

heating circuit.

▪ All installed piping and piping accessories (valve, connections,…)

must withstand the following temperatures:

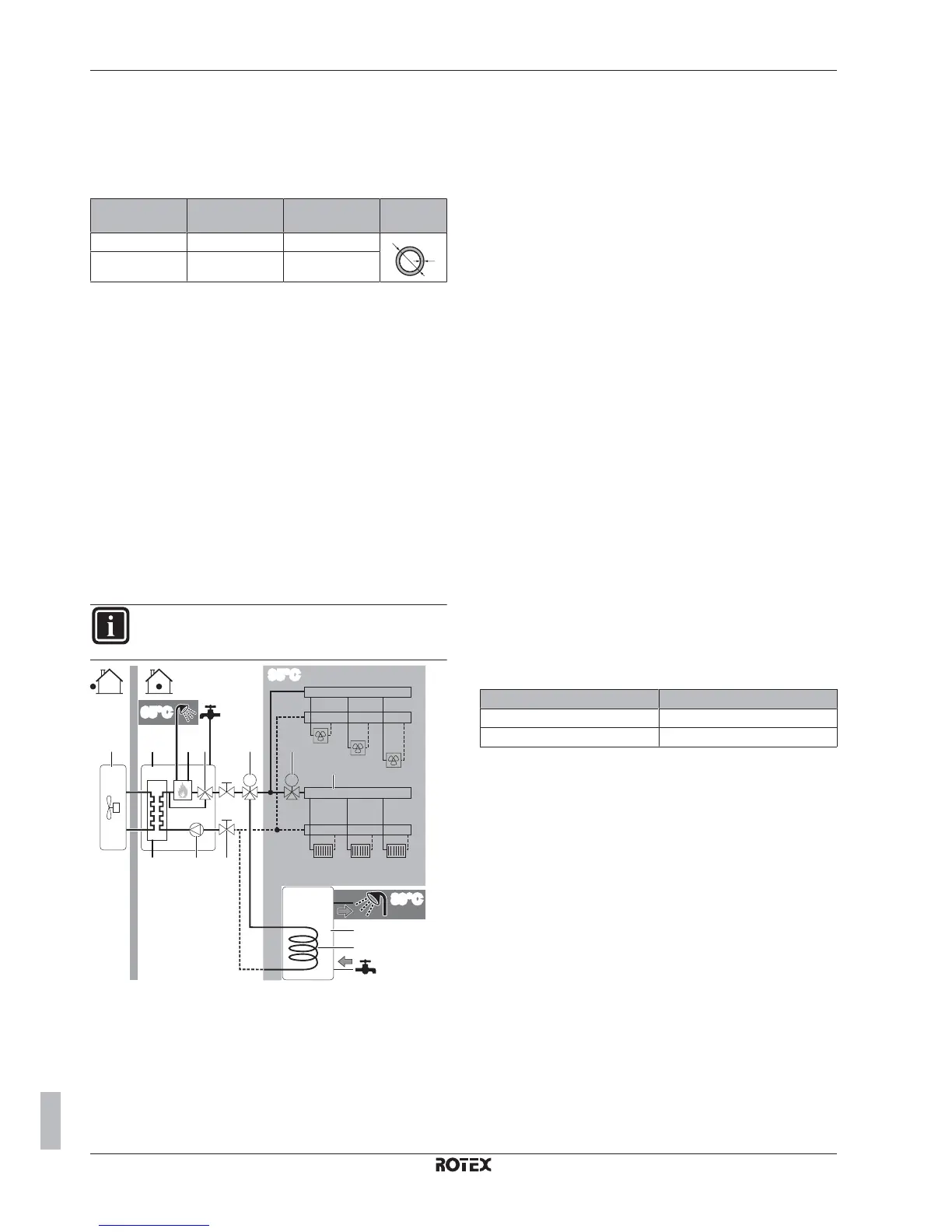

INFORMATION

The following illustration is an example and may NOT

match your system layout.

M

89°C

RAD1 RAD2 RAD3

95°C

65°C

M

a b d e

k

l

j

c f g

FCU1

FCU2

FCU3

hi

a

Outdoor unit

b

Indoor unit

c

Heat exchanger

d

Boiler

e

Bypass valve

f

Pump

g

Shut-off valve (field supply)

h

Motorised 2-way valve (field supply)

i

Motorised 3-way valve (in option kit)

j

Collector

k

Domestic hot water tank (optional)

l

Heat exchanger coil

FCU1...3

Fan coil unit (optional)

RAD1…3

Radiator

▪ Make all water piping connections in accordance with the

applicable legislation and the outlook diagram that is delivered

with the unit, respecting the water inlet and outlet.

▪ Do NOT use excessive force when connecting the piping.

Deformation of the piping can cause malfunctioning of the unit.

▪ Provide drain taps at all low points of the system in order to allow

complete drainage of the water circuit.

▪ Provide a proper drain for the pressure relief valve to avoid water

coming into contact with electrical parts.

▪ Provide air vents at all high points of the system, which must also

be easily accessible for servicing. An automatic air purge is

provided in the indoor unit. Check that the air purge is NOT

tightened too much, so that automatic release of air in the water

circuit is possible.

▪ Only use materials that are compatible with water used in the

system and with the materials used in the indoor unit.

▪ Check that all components in the field piping can withstand the

water pressure and water temperature.

▪ When using non-brass metallic piping, insulate the brass and non-

brass properly so that they do NOT make contact with each other.

This to prevent galvanic corrosion.

▪ Never use Zn-coated parts in the water circuit. Because the unit's

internal water circuit uses copper piping, excessive corrosion may

occur.

▪ Only use appropriate tooling to handle brass, which is a soft

material. If NOT, pipes will get damaged.

▪ Select the water piping diameter in relation to the required water

flow and the available external static pressure of the pump. See

"16 Technical data" on page 88 for the external static pressure

curves of the indoor unit.

▪ You can find the minimum required water flow for the indoor unit

operation in the following table. When the water flow is lower, flow

error 7H will be displayed and the indoor unit will be stopped.

Model Minimum water flow (l/min)

05 5

08 8

▪ When using a 3-way valve in the water circuit make sure that the

domestic hot water circuit and the floor heating circuit is fully

separated.

▪ When using a 2-way valve or a 3-way valve in the water circuit,

the maximum change-over time of the valve must be 60 seconds.

▪ It is strongly recommended to install an additional filter on the

heating water circuit. Especially to remove metallic particles from

foul heating piping, it is advised to use a magnetic or cyclone filter,

which can remove small particles. Small particles may damage

the unit and will NOT be removed by the standard filter of the heat

pump system.

▪ In case of old heating installations, it is recommended to use a dirt

separator. Dirt or sediment from the heating installation can

damage the unit and reduce its lifetime.

▪ If air, moisture or dust gets into the water circuit, problems may

occur. To prevent this:

▪ Only use clean pipes

▪ Hold the pipe end downwards when removing burrs.

▪ Cover the pipe end when inserting it through a wall, to prevent

dust and/or particles entering the pipe.

▪ Use a decent thread sealant to seal connections.

Loading...

Loading...