10 Commissioning

Installer reference guide

77

RVLQ05+08CAV4 + RHYHBH05AA + RHYHBH/X08AA +

RHYKOMB33AA

ROTEX HPU hybrid

4P355635-1 – 2013.05

10.6.2 To perform an underfloor heating screed

dryout

INFORMATION

Preferential kWh rate power supply cannot be used in

combination with underfloor heating screed dryout.

1 Go to [A.7.2]:

> Installer settings > Commissioning > UFH

screed dryout.

2 Set a dryout program.

3 Select Start dryout and press

.

4 Select OK and press

.

Result: The underfloor heating screed dryout starts and following

screen will be shown. It stops automatically when done. To stop it

manually, press

, select OK and press .

6FUHHGGU\RXW

7XH

6WRS

&XUUHQWVWHS

GK

r&

5HPDLQLQJ

'HVLUHG/:7

10.6.3 To readout the status of an underfloor

heating screed dryout

1 Press .

2 The current step of the program, the total remaining time, and

the current desired leaving water temperature will be displayed.

INFORMATION

There is limited access to the menu structure. Only the

following menus can be accessed:

▪ Information.

▪ Installer settings > Commissioning > UFH screed dryout

10.6.4 To interrupt an underfloor heating screed

dryout

When the program is stopped by an error, an operation switch off, or

a power failure, the U3 error will be displayed on the user interface.

To resolve the error codes, see "13.4 Solving problems based on

error codes" on page 84. To reset the U3 error, your User

permission level needs to be Installer.

1 Go to the underfloor heating screed dryout screen.

2 Press

.

3 Press

to interrupt the program.

4 Select OK and press

.

Result: The underfloor heating screed dryout program is stopped.

When the program is stopped due to an error, an operation switch-

off, or a power failure, you can read out the underfloor heating

screed dryout status.

5 Go to [A.7.2]:

> Installer settings > Commissioning > UFH

screed dryout > Dryout status > Stopped at and followed by the

last executed step.

6 Modify and restart the execution of the program.

10.7 To perform an air purge on the gas

supply

1 Connect a suitable gauge on the gas valve. Static pressure

MUST be 20 mbar.

2 Select test program " ". See "10.8 To perform a test run on the

gas boiler" on page 77. Static pressure MUST be 20 mbar (+

or – 1 mbar). If the working pressure is <19 mbar, the gas boiler

output will be reduced and the correct combustion reading may

NOT be obtained. Do NOT adjust the air and/or gas ratio. To

obtain sufficient working pressure, gas supply MUST be correct.

INFORMATION

Make sure the working inlet pressure does NOT interfere

with other gas appliances installed.

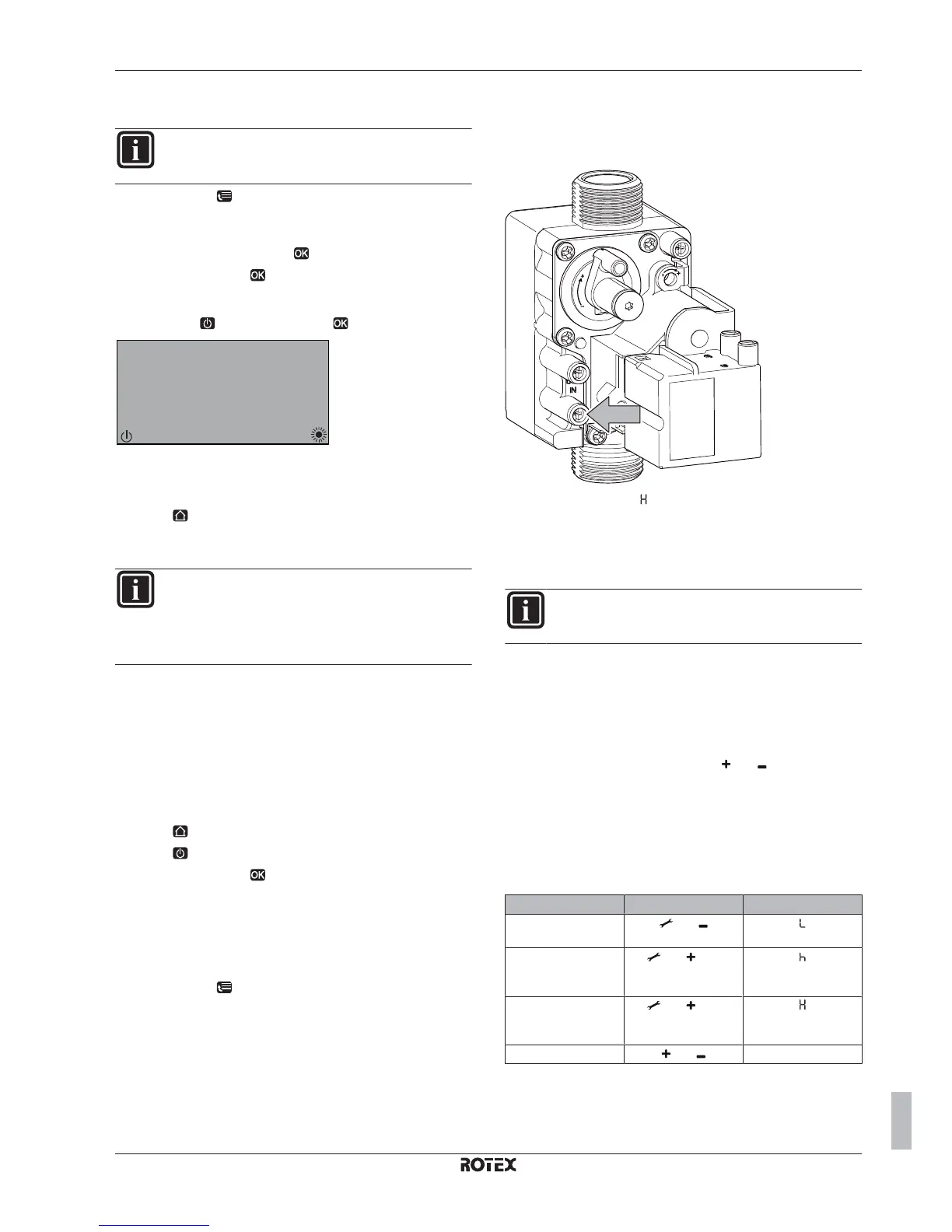

10.8 To perform a test run on the gas

boiler

The gas boiler has a test run function. Activation of this function will

result in starting the operation at a fixed fan speed, without the

control functions being actuated. The safety functions remain active.

The test run can be stopped by pressing and simultaneously or

will end automatically after 10 minutes. To perform a test run, switch

off the system with the user interface.

Make sure the user interface shows the home screens and that the

space heating and domestic hot water demands are turned off.

There may be no error on the gas boiler or the heat pump module.

During a gas boiler test run, "busy" will be displayed on the user

interface.

Program Button combination Display

Burner ON at

minimum power

and

Burner ON, maximum

space heating power

setting

and (1×)

Burner ON, maximum

domestic hot water

setting

and (2×)

Stop test program and Actual situation

Loading...

Loading...