7 Installation

Installer reference guide

41

RVLQ05+08CAV4 + RHYHBH05AA + RHYHBH/X08AA +

RHYKOMB33AA

ROTEX HPU hybrid

4P355635-1 – 2013.05

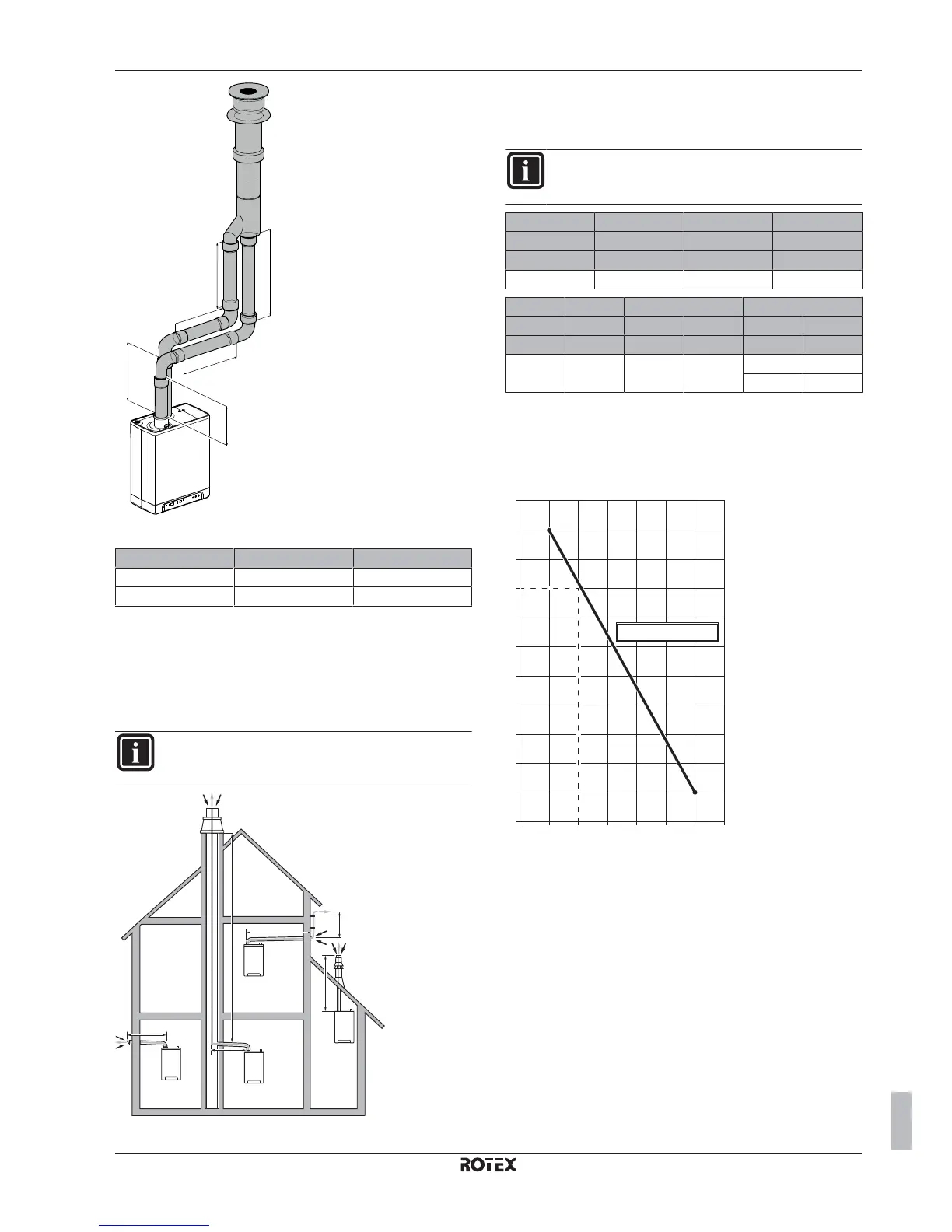

L6

L4

L3

L1

L2

L5

Sample calculation for dual pipe application

Pipe Pipe length Total pipe length

Flue pipe L1+L2+L3+(2×2) m 13 m

Air supply L4+L5+L6+(2×2) m 12 m

Total piping length = sum of the straight pipe lengths + sum of the

equivalent pipe length of bends/elbows.

7.10.4 Appliance categories and pipe lengths

Following installation methods are supported by the manufacturer.

Single boiler installation

INFORMATION

All piping lengths in the tables below are maximum

equivalent piping lengths.

1

L1

L1

L2

L1

3

2

C

53

C

93

C

13

C

33

L2

4

L1

The horizontal flue MUST be installed under a 3° fall towards the

boiler (50 mm per meter) and MUST be supported with a minimum

of 1 bracket at each meter length. Best recommended position of the

bracket is just before the joint.

INFORMATION

Flexible flue gas lines may NOT be used in horizontal

connection sections.

C

13

(1) C

33

(2) C

13

(1) C

33

(2)

60/100 60/100 Twin-80 Twin-80

L1 (m) L1 (m) L1 (m) L1 (m)

10 10 80 21

C

13

(1) C

33

(2) C

93

(4) C

53

(3)

80/125 80/125 80/125 80 60/100 60

L1 (m) L1 (m) L1 (m) L2 (m) L1 (m) L2 (m)

29 29 10 25 6 1

1 10

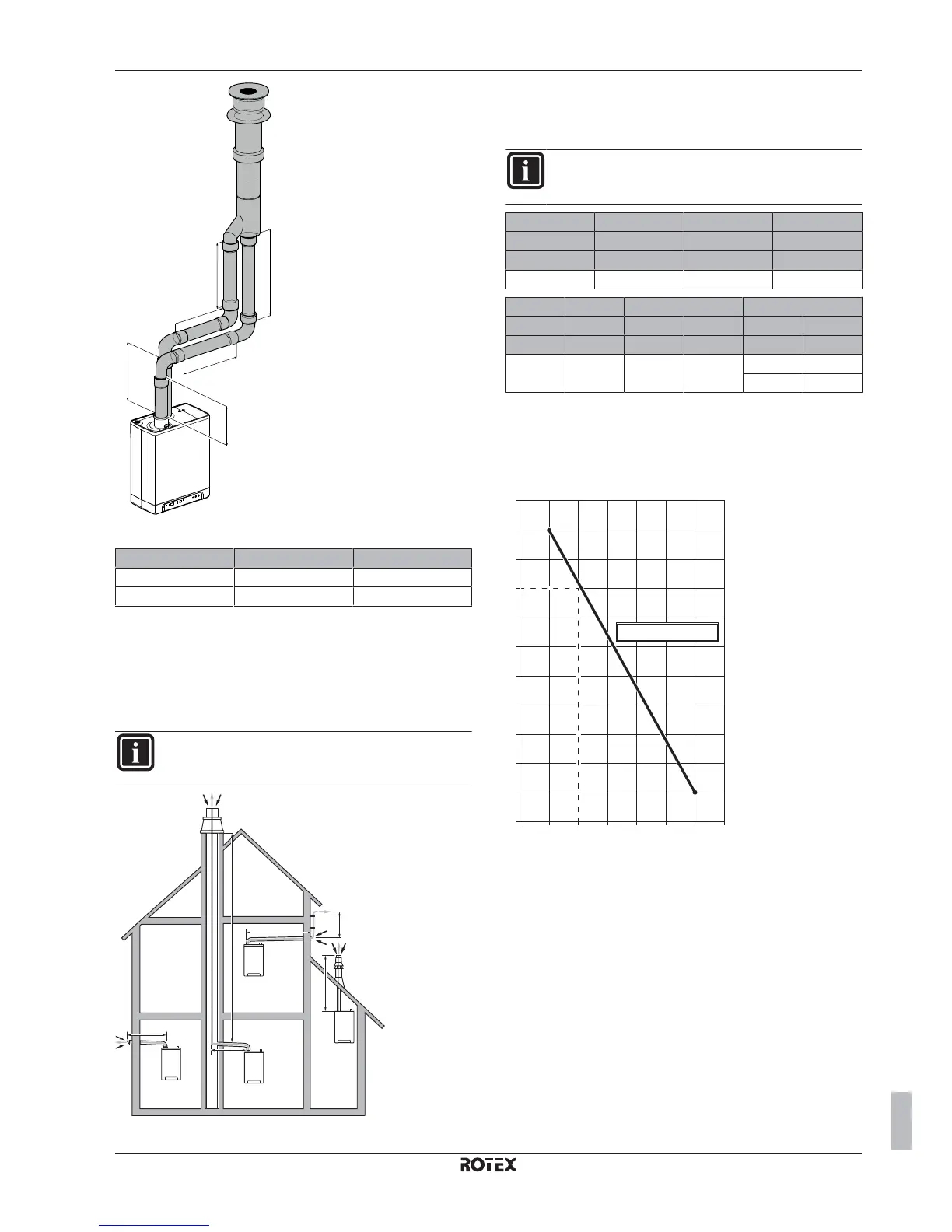

Special remark regarding C

53

: The maximum lengths for L1 and L2

are related to each other. First determine the length of L1; then

make use of the graph below to determine the maximum length of

L2. For example: if the length of L1 is 2 m, L2 can maximally be 8 m

long.

7

6

5

10

9

11

8

3

4

2

1

0

L2

L1

01234 675

L2=–1.8×L1+11.8

Loading...

Loading...