Keeping the World Flowing

25

H. To decrease angular stroke, rotate stop bolt (7) clockwise

I. Remove pressure

J.

Verify the newly obtained angular position with one stroke

K. Repeat operations A to C and H to K, until the desired

angle is obtained

L. Hold stop bolt (7) with a wrench and tighten stop nut (6).

Verify seal washer (5) is properly placed

A small amount of oil dripping from the stop bolt is normal to

happen during the above procedure

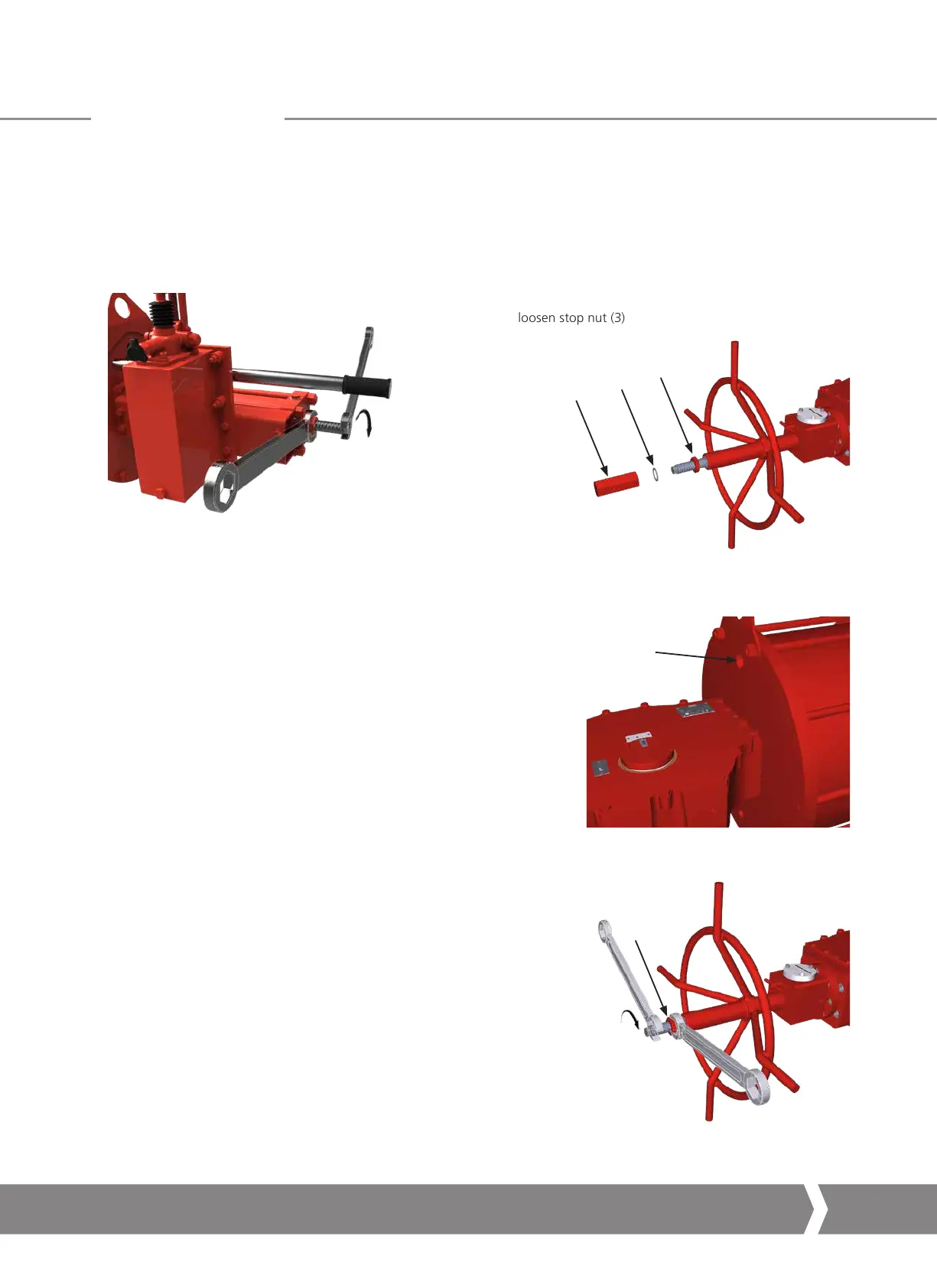

12.7.9 Double-Acting Actuator with Type MD Manual

Override Stop Bolt Setting

Perform the following operations after cylinder stop bolt setting.

Manual override must be disengaged to perform operation. Verify

it is disengaged, otherwise rotate the engaging lever by 180 °C.

Adjust the stop bolt located in the manual override as follows:

A. Remove cap nut (1) and relative seal washer (2) and

loosen stop nut (3)

2

1

3

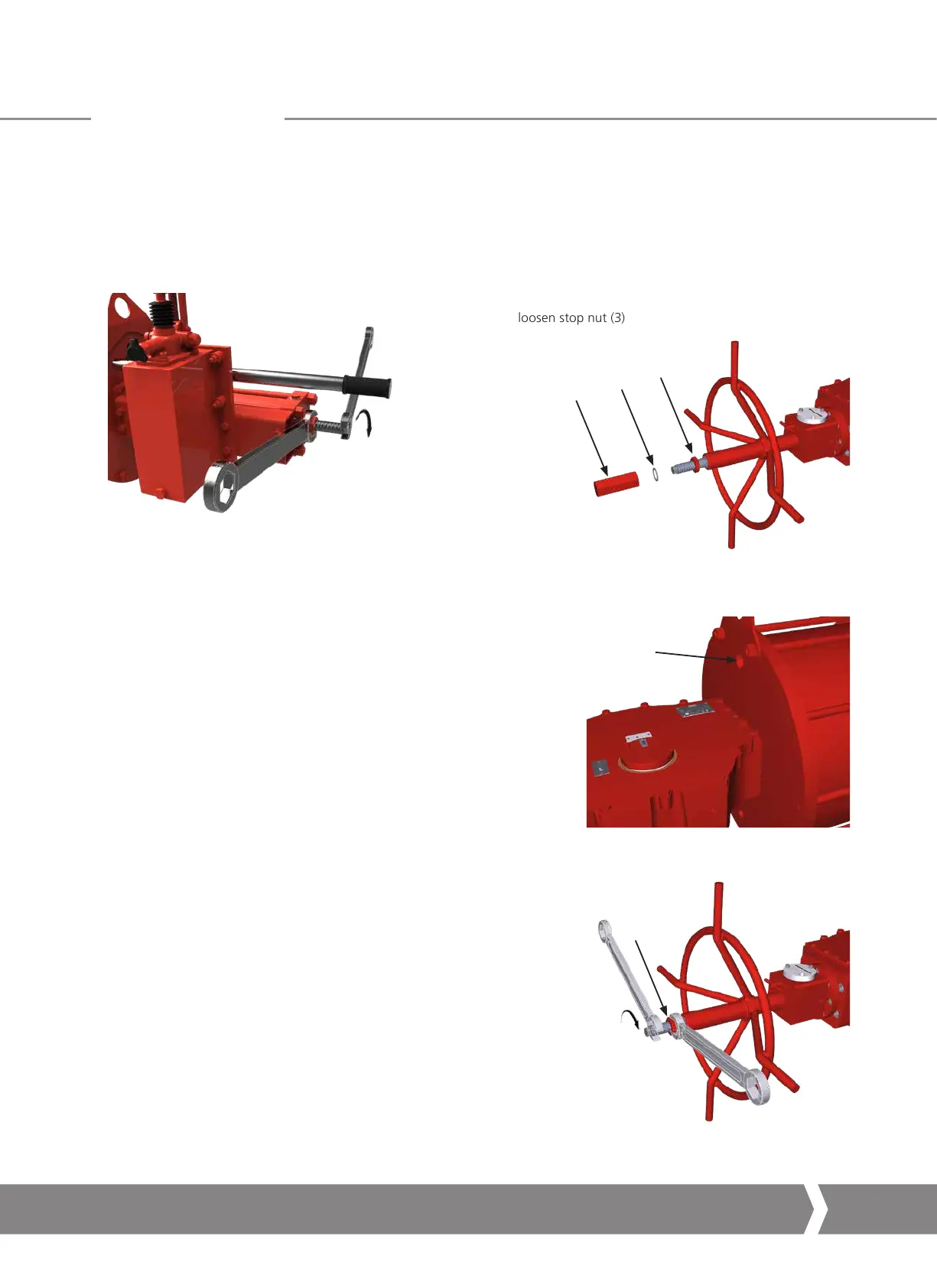

B. Pressurize the cylinder from connection X1

X1

C. To increase angular stroke, rotate stop bolt (5) anti-clockwise

5

12.0 Operation

A4 US

US

A4

US

A4

A4 US

Loading...

Loading...