136 EB 8384-2 EN

Appendix

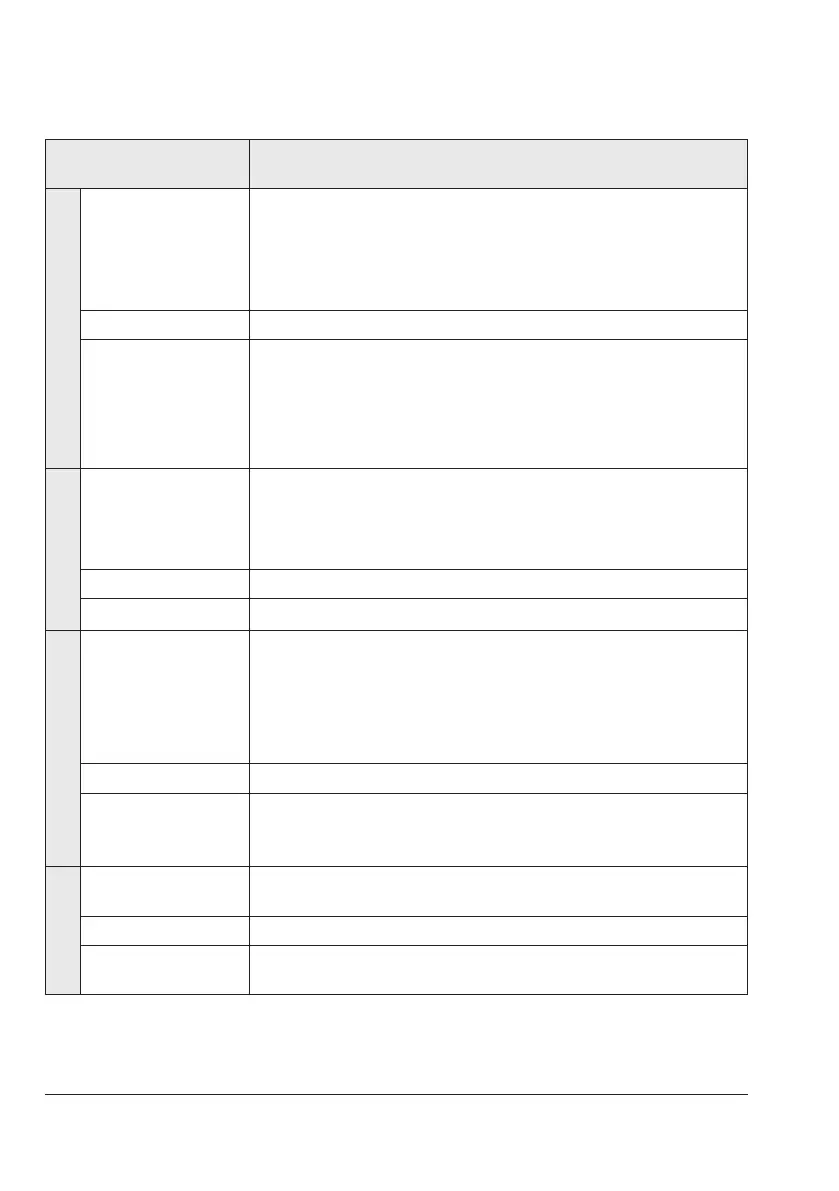

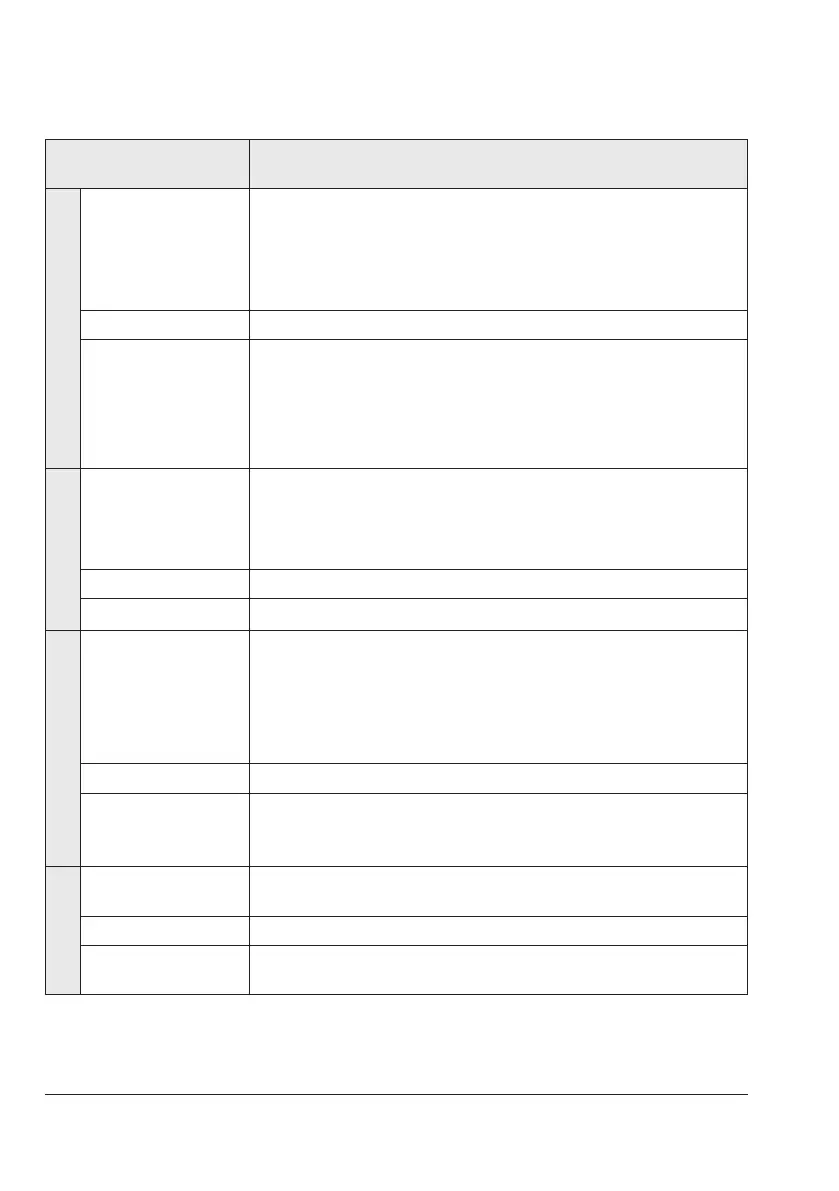

Error codes – Recommended

action

Condensed state message active, when prompted, Err appears.

Whenfaultalarmsexist,theyaredisplayedhere.

52 Attachment • Invalid positioner attachment

• Nominaltravel/angle(Code5)couldnotbeachievedduringNOM

initialization (no tolerance downwards permissible).

• Mechanical or pneumatic fault, e.g. wrong lever selected or supply

pressure too low to move to the required position.

Statusclassication [Maintenance required]

Recommendedaction Checkattachmentandsupplypressure.Re-initializethepositioner.

Under certain circumstances, it may be possible to check the maximum

travel/anglebyenteringtheactualpinpositionandthenperforminga

MAX initialization.

After initialization has been completed, the Code 5 indicates the

maximum achieved travel or angle.

53 Initialization time

exceeded

(Init time >)

Initialization takes too long. The positioner returns to the previous

operating mode.

• No pressure in supply line or pneumatic leakage

• Supply air failure during initialization

Statusclassication [Maintenance required]

Recommendedaction

Checkattachmentandsupplyairline.Re-initializethepositioner.

54 Initialization – solenoid

valve

1)

Asolenoidvalveisinstalled(Code45=YES)andhasnotbeen

connected or not properly. As a result, actuator pressure cannot

build up. The alarm is generated when you attempt to initialize the

positioner.

2)

If you attempt to initialize the positioner from the fail-safe position

(SAFE).

Statusclassication [Maintenance required]

Recommendedaction

1)

Check connection and supply voltage of the solenoid valve (Code 45

High/Low).

2)

SettheMANmodeinCode0.Re-initializethepositioner.

55 Transit time too short

(transit time <)

Actuator transit times detected during initialization are so short that

optimal positioner tuning is impossible.

Statusclassication [Maintenance required]

Recommendedaction Checkthevolumerestrictionsettingasdescribedinsection7.2.Re-

initialize the positioner.

Loading...

Loading...