EB 8384-2 EN 79

Mounting and start-up

5.12 Retrotting an inductive

limit switch

Required retrot kit:

Limit switch Order no. 1402-1770

The same requirements apply to retrotting a

unit as to servicing the positioner. For explo-

sion-protected positioners, the requirements

in Servicing explosion-protected devices

need to be kept. Check the "Limit switch, in-

ductive" box on the nameplate after install-

ing the limit switch.

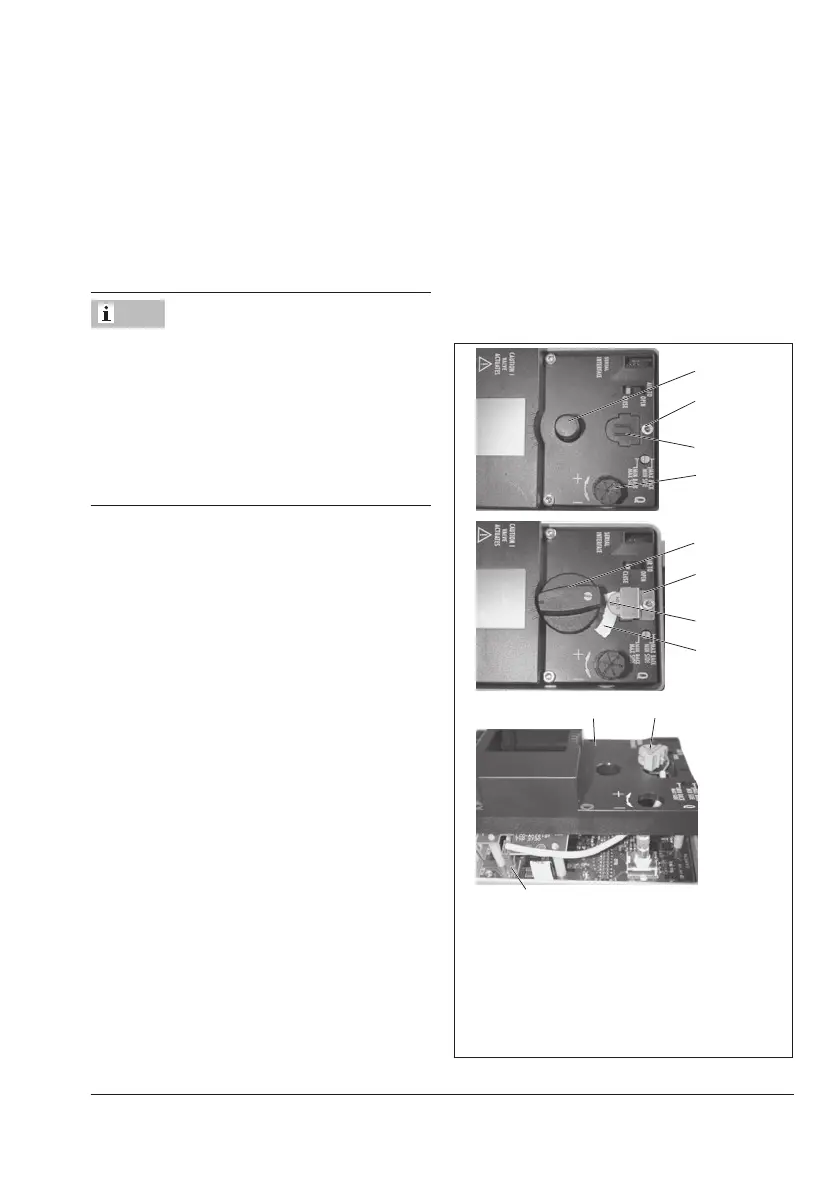

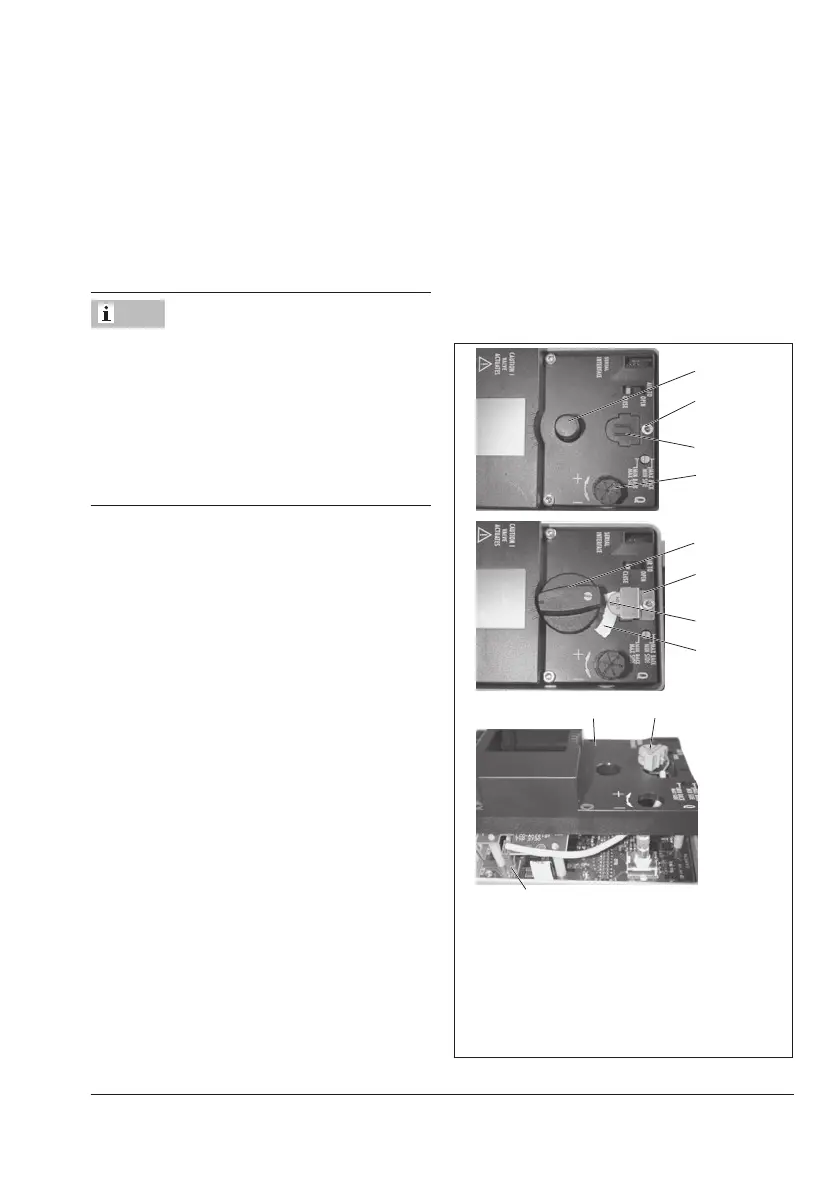

1. Take off the rotary pushbutton (3) and cap

(1),unthreadthevefasteningscrews(2)

and lift off the plastic cover (9) together

with the display, taking care not to dam-

age the ribbon cable (between PCB and

display).

2. Use a knife to cut an opening at the

marked location (4).

3. Push the connector (11) with cable

through the opening and secure the prox-

imity switch (7) on the cover with a dot of

glue.

4. RemovethejumperatthesocketX7ofthe

top board and insert the cable connector

(11).

5. Guide the cable in such a manner that the

plastic cover can be placed back onto the

positioner.Insertthexingscrews(2)and

screw tight. Attach the clamping plate (8)

onto the proximity switch.

6. Attach the rotary switch (5). Make sure

theattenedsideofthepositionershaftis

turned so that the rotary switch (5) can be

attached with the metal tag next to the

proximity switch.

7. On start-up of the positioner, set the op-

tioninductivealarmunderCode38from

No to YES.

1

2

3

4

5

8

6

7

9

7

Socket X7 (11)

1 Cap 6 Metal tag

2 Screw 7 Proximity switch

3 Rotarypushbutton 8 Clamping plate

4 Marking 9 Plastic cover

5 Rotaryswitch 11 Connector

Fig.31: Retrotting an inductive limit switch

Note

Loading...

Loading...