- 6 -

Section1 Product description

BLPS is designed to protect the safety of the fingers and arms of the operator in close to the

region of upper mold die tip. Under the premise of installing the device correctly and

complying with the safety instructions, Operators can be allowed to keep close contact with

workpiece and be provided effective protection under high-speed clamping.

1.1.

Applications

Objects protected by BLPS must meet following requirements:

1

)

BLPS only protects the objects which can block light beam completely, cannot detect

transparent and/or translucent objects;

2)The detecting beam must be adjusted to the correct detecting position;

3)The safe distance is determined by the response time of BLPS and the bender, it must

be greater than the braking distance of the bender;

4

)

The bender must be able to stop any where in its cycle;

5)The bender must not present a hazard from flying parts;

6

)

The bender should be in good operating state and stop in the prescribed braking time;

7

)

All applicable governmental and local rules, codes, and regulations must be satisfied.

This is the user’s and employer’s responsibility;

8)All safety-related machine control elements must be designed so that an alarm in the

control logic or failure of the control circuit does not lead to failure to danger;

9)Do not use radio transmitting and receiving equipments near BLPS such as

transceivers.

Do not use BLPS in the following environments:

1

)

Areas with heavy smoke, particulate matter, and corrosives;

2

)

Areas exposed to intense interference light, such as direct sunlight;

3)Areas with high humidity where condensation is likely to occur;

4

)

Areas exposed to vibration or shock levels higher than in the specification provisions;

5)Areas where the product may come into contact with water;

6)Areas where the product may get wet with oil that can solve adhesive;

7)Environments where flammable or explosive gases are present.

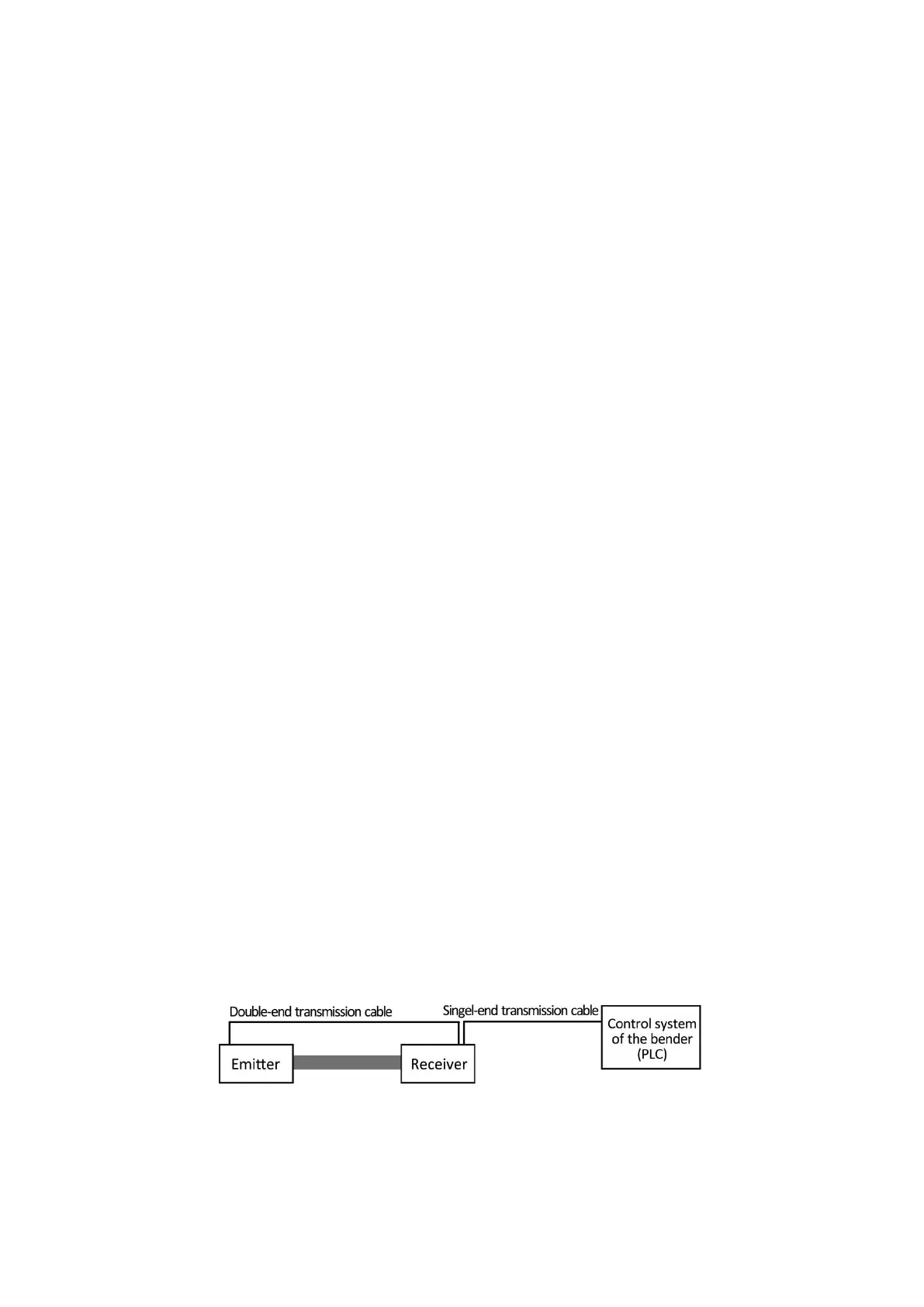

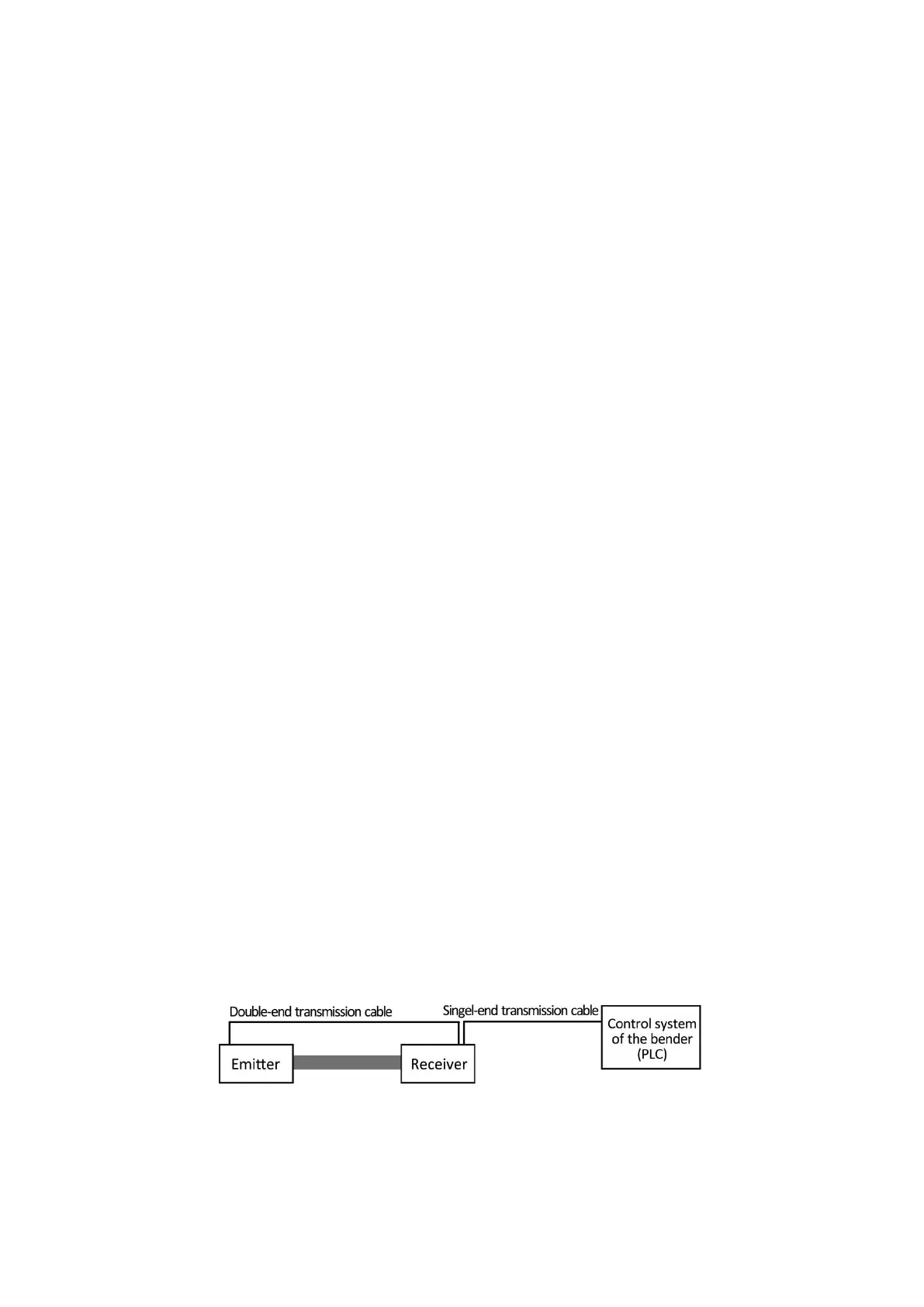

1.2. System components

BLPS consists of detection sensor (a emitter and a receiver), controller and cables.

1.2.1 Sensor used alone

Sensor can be used for CNC bender with PLC programming functionality separately.

Fig.1.1.A Operation schematic diagram

Loading...

Loading...