Do you have a question about the Seagate ST212 and is the answer not in the manual?

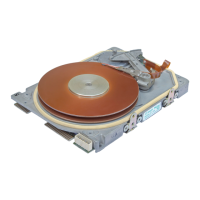

Details on drive capacity, unformatted and formatted.

Defines access time and specifies step pulse period.

Covers rotational speed, latency, density, tracks, and transfer rate.

Dimensions and weight of the drive.

MTBF, PM, MTTR, service life, read error rates, bit jitter, media defects.

Ambient temperature, gradient, humidity, altitude, and shock limits.

Details voltage, current, and power requirements for the drive.

Specifies mounting orientations, dimensions, and clearances.

Details the 34-pin connector for control and status signals.

Details the 20-pin connector for read/write data signals.

Describes the 4-pin connector for DC power transmission.

Identifies the lug for frame grounding and its connector type.

Explains the use of shunt J9 for configuration options.

How the DRIVE SELECT line selects and addresses the drive.

Describes daisy-chain configuration for multiple drives.

Configuration for radial drive connection.

Internal latching mechanism for the WRITE FAULT signal.

Function used during manufacturing, not recommended for field use.

Signals for selecting Read/Write heads in binary code.

Controls data writing and inhibits carriage motion if WRITE FAULT is active.

Initiates Read/Write head motion; pulse rate determines access method.

Minimizes access time by buffering pulses at an accelerated rate.

Stepper motor settled and SEEK COMPLETE issued after last Step pulse.

Drive enters mode when excessive Step pulses would go beyond track limits.

Defines the direction of head movement with each STEP pulse.

Signal activated by the controller to select and address the drive.

Status signal indicating drive selection by the host system.

Indicates the beginning of a track once per revolution.

Signal active when heads are positioned at Cylinder Zero.

Indicates drive is ready for Read/Write/Step when SEEK COMPLETE is true.

Signal indicating head settling on track after seek completion.

Indicates a condition that may cause an incorrect write operation.

Conditions under which WRITE FAULT signal is issued.

Describes fault detection mechanisms on PC Board 20292-XXX.

Monitors voltage and head select for fault conditions.

Describes selectable options for clearing the Write Fault latch.

Describes fault detection mechanisms on PC Board 20243-XXX.

Monitors voltage lines for low voltage conditions.

Monitors head selection for proper operation.

Details the write operation process for PC Board 20292-XXX.

Describes MFM data transmission for writing to the disc.

Initiates write sequence and controls data to the selected head.

How differential MFM data is processed for writing.

Recommends precompensation for optimal performance on specific cylinders.

Details the write operation process for PC Board 20243-XXX.

Initiates write sequence and applies voltage to the selected head.

Receives differential write data and processes it.

Suggests a format example for sectors and data fields.

Details the read operation process for PC Board 20292-XXX.

Transmits recovered data via differential MFM READ DATA lines.

Binary decoder selects head based on head select line status.

Amplifies read signal and acts as a high-pass filter.

Attenuates high frequency noise outside the normal data signal range.

Converts amplified analog data to differential MFM Read data.

Details the read operation process for PC Board 20243-XXX.

Selects desired head using a binary decoder based on select lines.

Amplifies the read signal and acts as a high-pass filter.

Attenuates high frequency noise outside the normal data signal range.

Shifts amplified data to improve accurate detection at zero crossing.

Detects bit position by signal slope crossing the zero threshold.

Ignores spurious data bits caused by signal decay.

Converts raw digital data to differential data for noise immunity.

Explains the microprocessor's role in monitoring and controlling drive functions.

Details the microprocessor's control of drive functions on this board.

Details motor speed control for PC Board 20292-XXX.

Senses spindle position and provides dynamic feedback for motor speed.

Controls spindle motor speed and integrates error messages.

Details motor speed control for PC Board 20249-XXX.

Senses spindle position and provides dynamic feedback for motor speed.

Outputs a low pulse indicative of speed error.

Smooths incoming error pulses for easier integration.

Integrates speed error and determines current flow per revolution.

Senses current level and limits it during motor start-up.

Signal maintained by MPU to control motor spin-up.

Supplies current to motor phases and controls current level.

Shorts motor phases to ground to stop spindle upon power interruption.

Illustrates test point locations on PC Board 20292-XXX.

Monitors Differential Read Data at test points 1 and 2.

Monitors the Track Ø sensor at IC 3B, pin 1.

Monitors the Index sensor at test point 9.

Illustrates test point locations on PC Board 20243-XXX.

Monitors Differential Read Data at test points 1 and 2.

Monitors Read data from the time domain filter at test points 3 and 4.

Monitors the Track Ø sensor at test point 5.

Monitors the Index Sensor at test point 6.

Procedures for components accessible without special tools or cleanrooms.

Steps for removing the main control PCB.

Steps for removing the motor control PCB.

Procedure for removing the index sensor.

Procedure for installing the full-height front panel.

Procedure for removing the Track Ø sensor.