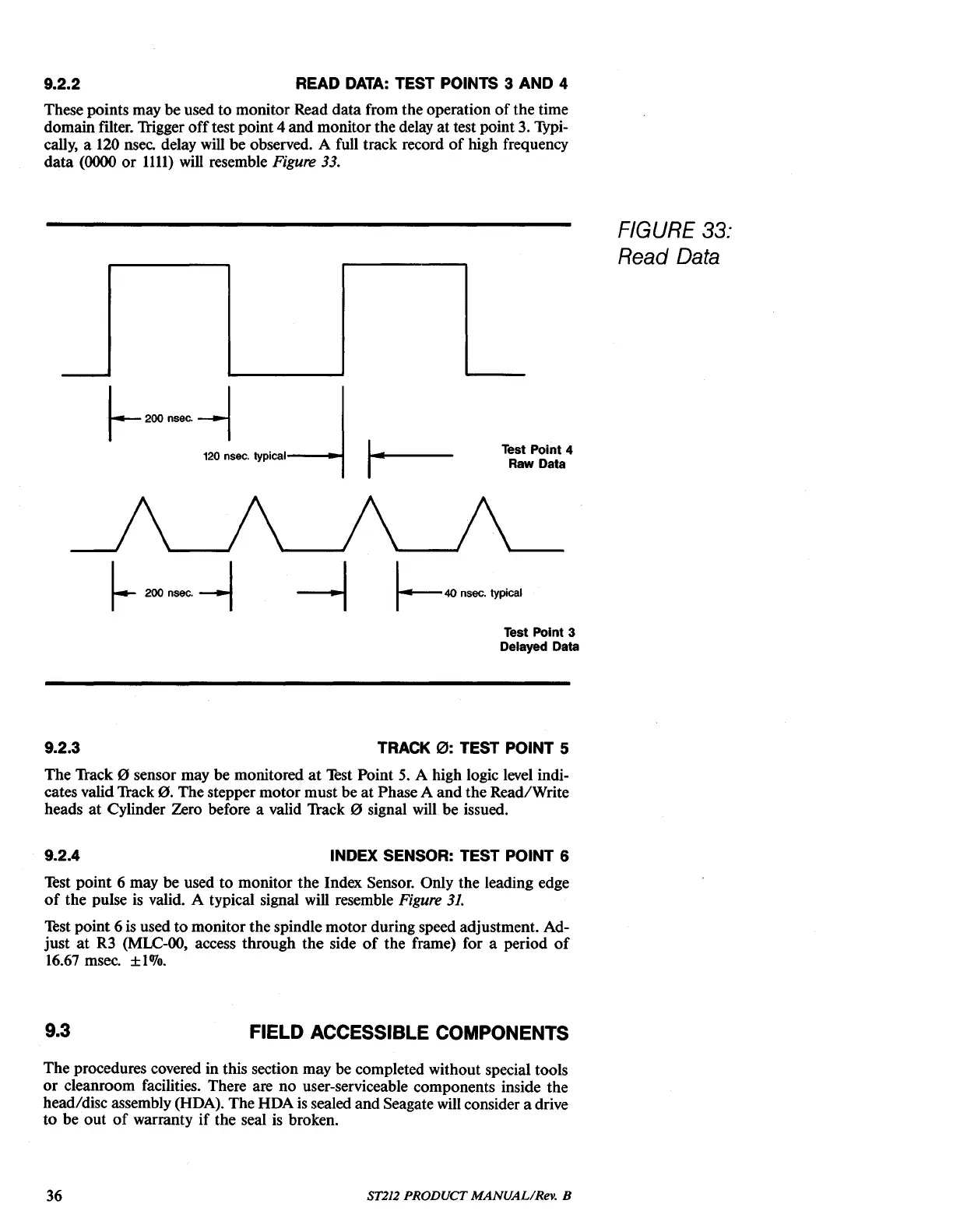

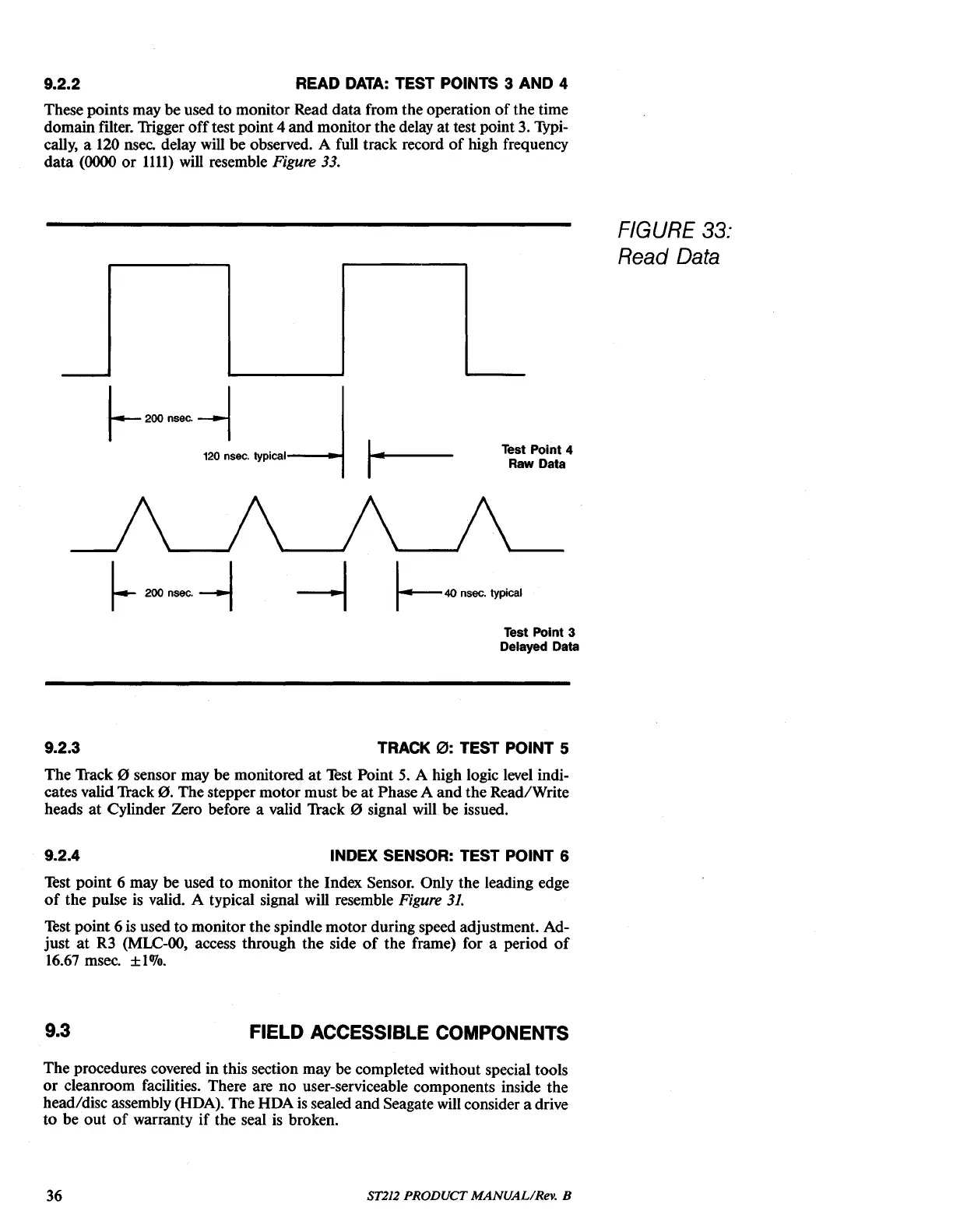

9.2.2

READ

DATA:

TEST POINTS 3 AND 4

These points may be used

to

monitor Read

data

from the operation

of

the time

domain filter.

liigger

off

test point 4 and monitor the delay at test point 3. Typi-

cally, a 120 nsee. delay will be observed. A full track record

of

high frequency

data

(0000

or

1111)

will resemble Figure 33.

FIGURE

33:

Read Data

Test Point 4

Raw Data

Test Point 3

Delayed Data

9.2.3

TRACK

0:

TEST POINT 5

The

lfack

0 sensor may be monitored

at

lèst

Point

5.

A high logic level indi-

cates valid Track

0.

The stepper motor must be

at

Phase A

and

the Read/Write

heads

at

Cylinder Zero before a valid

lfack

0 signal will

be

issued.

9.2.4

INDEX SENSOR: TEST POINT 6

Test point 6 may be used to monitor the Index Sensor. Only the leading edge

of

the pulse

is

valid. A typical signal will resemble Figure 3J.

Test point 6 is used to monitor the spindle motor during speed adjustment. Ad-

just

at

R3

(MLC-OO,

access through the side

of

the frame) for a period

of

16.67 msec.

±IOJo.

9.3

FIELD ACCESSIBLE COMPONENTS

The procedures covered in this section may be completed without special tools

or

cleanroom facilities. There are

no

user-serviceable components inside the

head/disc assembly (RDA). The

RDA

is

sealed and Seagate will consider a drive

to

be

out

of

warranty

if

the seal

is

broken.

36

ST212 PRODUCT MANUAL/Rev. B

Loading...

Loading...