Perimeter layout guidelines

FlexZone Product Guide Page 15

Cable layout guidelines

• The full length of sensor cable must be mounted on the same type of surface.

• The maximum length of cable for each side of the processor is 300 meters (984 ft.).

• The smallest allowable bend radius for FlexZone sensor cable is 10 cm (4 in.).

• The smallest allowable bend radius for armored sensor cable is 15 cm (6 in.).

• Keep vertical drops of sensor cable to less than 1 m (3.3 ft.).

• The sensor cable should follow the ground contour to maintain a constant height above the

ground.

Cable length calculator (flexible fences)

Typically, fence coverage requires approximately 10% more cable than the linear fence length.

The following table provides a guideline for calculating the amount of sensor cable required for a

2.44 m (8 ft.) fence (in meters):

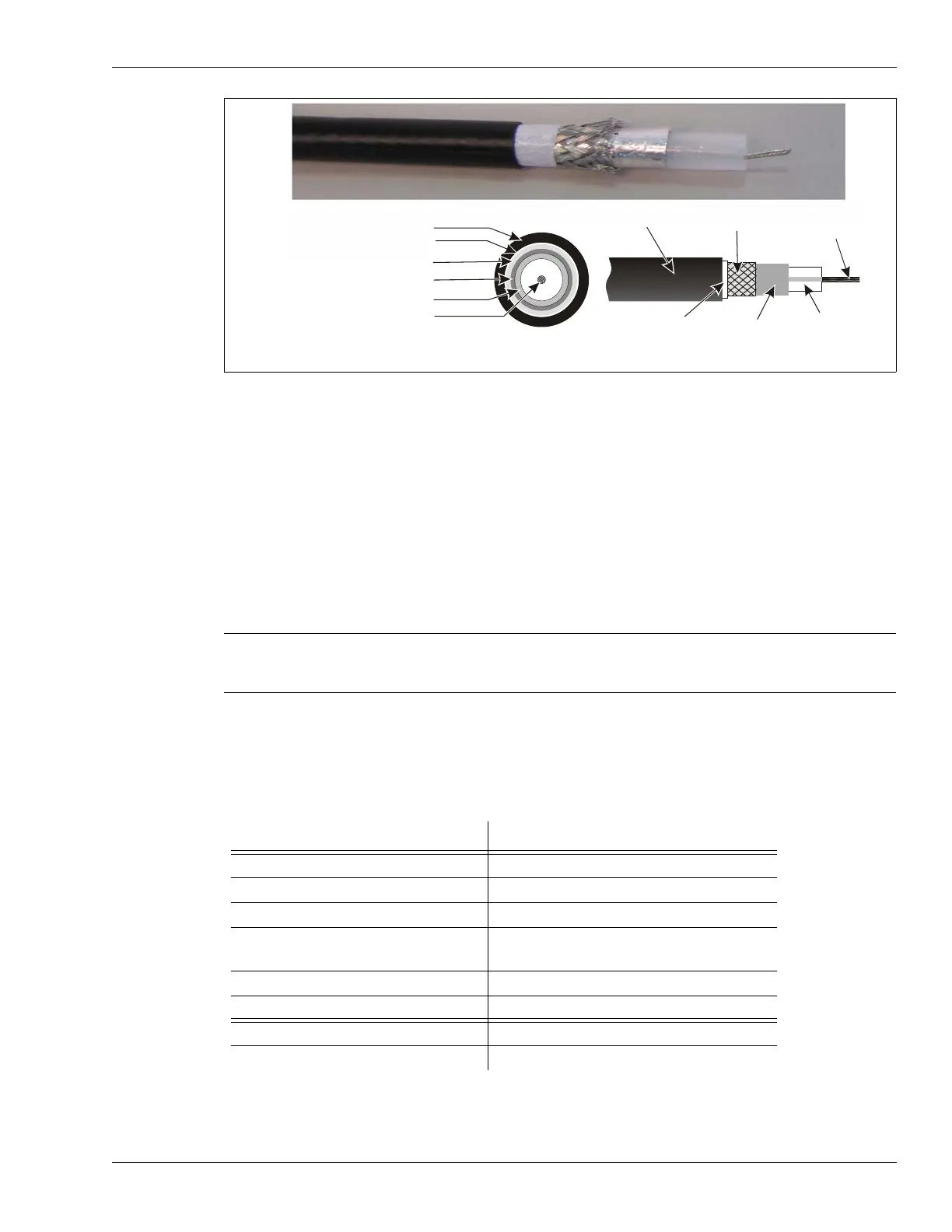

Figure 7: FlexZone sensor cable description

Note Senstar strongly recommends installing the sensor cable on the

secure side of the perimeter (the side of the fence opposite the

threat).

zone element required cable length (in meters)

start point + 1 m

service loops + 0.75 m X (linear cable length / 50)

zone demarcation loops + 3 m X number of zone boundaries

sensitivity loops + 3 m X number of corner and heavy

gauge posts

cable terminations and splices + 0.5 m each

linear fence length + _ _ _ _ _ (fence length)

required length of cable per pass = _ _ _ _ _ (total length)

total length X number of passes = _ _ _ _ _ cable length (max. 300 m)

polyethylene

jacket

braided

shield

stranded center

conductor

clear tube

foil

clear tube

center conductor

aluminum foil

braided shield

outer black jacket

mylar film*

mylar film*

FlexZone sensor cable may include a mylar film between the outer black jacket and the braided shield.

The mylar film is used in the cable extrusion process and has no effect on the cable’s function.

*

Loading...

Loading...