Perimeter layout guidelines

Page 20 FlexZone Product Guide

(1.75 in. to 5 in.). The hardware required for surface-mounting the processor is customer-supplied.

The FlexZone enclosure is hinged and includes a lockable latch (requires a Customer-supplied

pad lock).

Power source and wiring

The FlexZone processor can operate on a wide range of input voltages (12 to 48 VDC). The power

supply, the number of processors, and the lengths of the power cable runs will determine the

gauge of the power cable wiring that is required. In locations where AC power may not be stable or

reliable, an uninterruptable power supply (UPS) should be used for primary power. Assume a

maximum power consumption of 2.5 W per FlexZone processor (with NIC).

Power over the sensor cables

A group of up to five FlexZone processors can share power via the connected sensor cables. In

this case, the central processor is connected to a 48 VDC power supply. The sensor cables from

the central processor are connected to the two adjacent processors (one on each side). The

processor connected to the power supply requires a stable, low resistance earth ground

connection, which also serves as the ground reference for the connected block of processors.

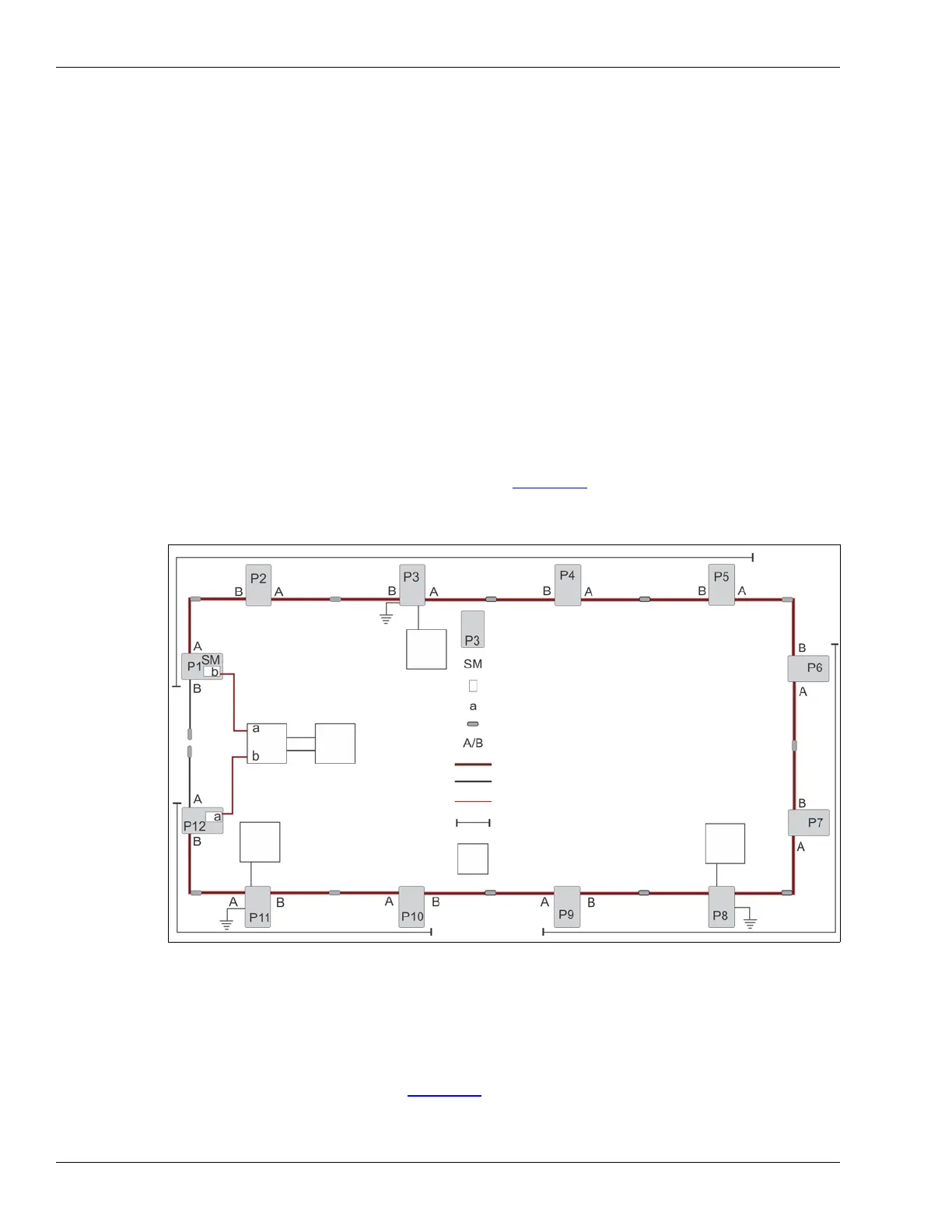

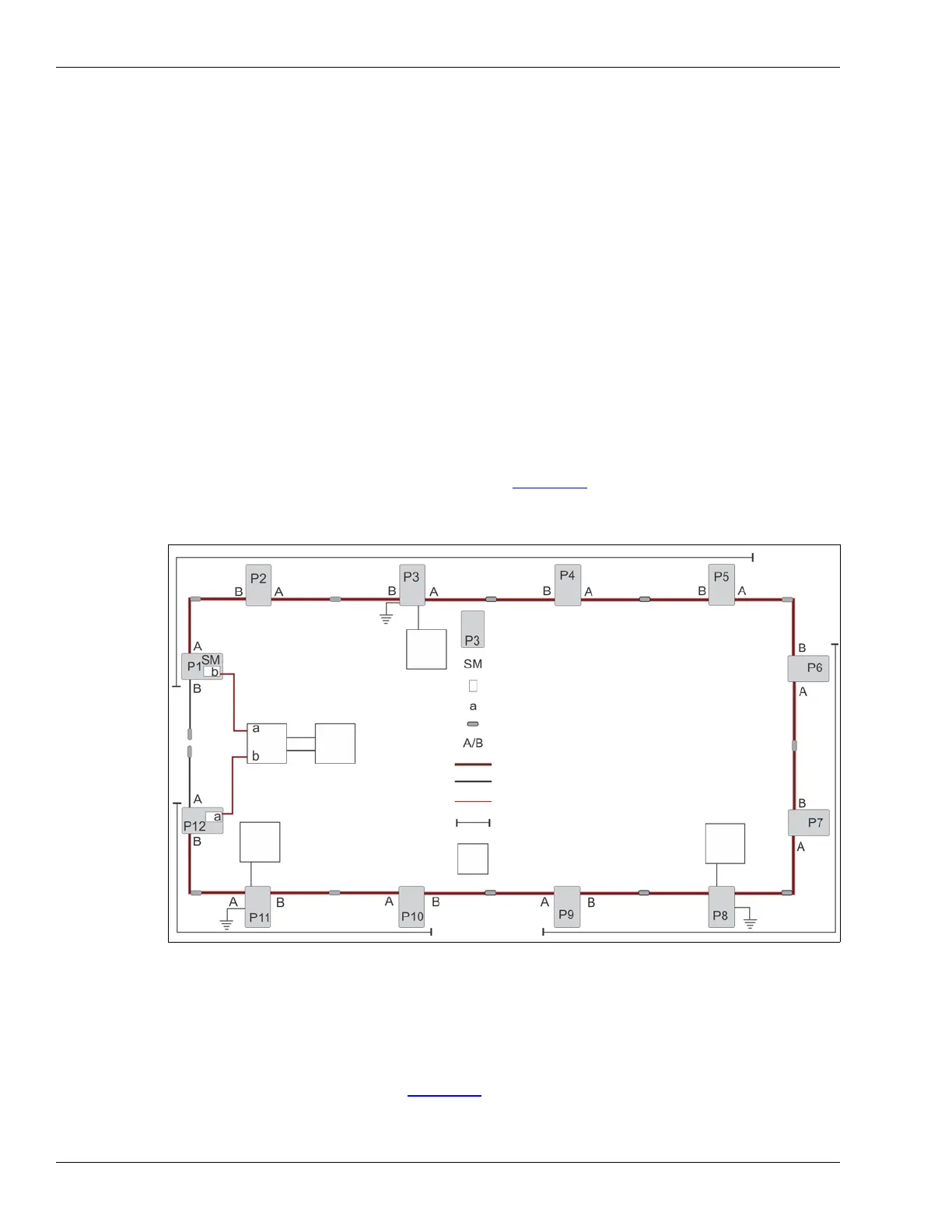

Power and data distribution is setup via the UCM. Figure 12:

illustrates a 7.2 km (4.5 mi.) 12

processor FlexZone perimeter with power and data over the sensor cables, and redundant Silver

Network communications.

Auxiliary device output power

Processors that are receiving power over the sensor cables can supply up to 2 W of power to an

auxiliary security device through T4, the power connector. The output power is at the same voltage

as the received power input via the sensor cables. The minimum required voltage to enable power

over the sensor cables is 38 VDC. Figure 76:

illustrates connection diagrams of a FlexZone

processor supplying power and carrying alarm data for an UltraWave microwave sensor in both

Local and Remote control modes.

Figure 12: Power and data distribution via sensor cables

48

VDC

48

VDC

48

VDC

NIU

SMS

FlexZone processor

NIC

comm channel

splice/termination

cable side

sensor cable with power & data

network wiring

48 VDC power block

sync master

48 VDC power supply

processor network address

sensor cable

Loading...

Loading...