MX-5001N SIMULATION 6 – 12

3-10

Purpose

Adjustment

Function (Purpose)

Used to adjust the finisher.

Section

Finisher

Operation/Procedure

1) Select an adjustment target item with [↑] [↓] key on the touch

panel.

2) Enter the set value with 10-key.

3) Press [OK] key. (The set value is saved.)

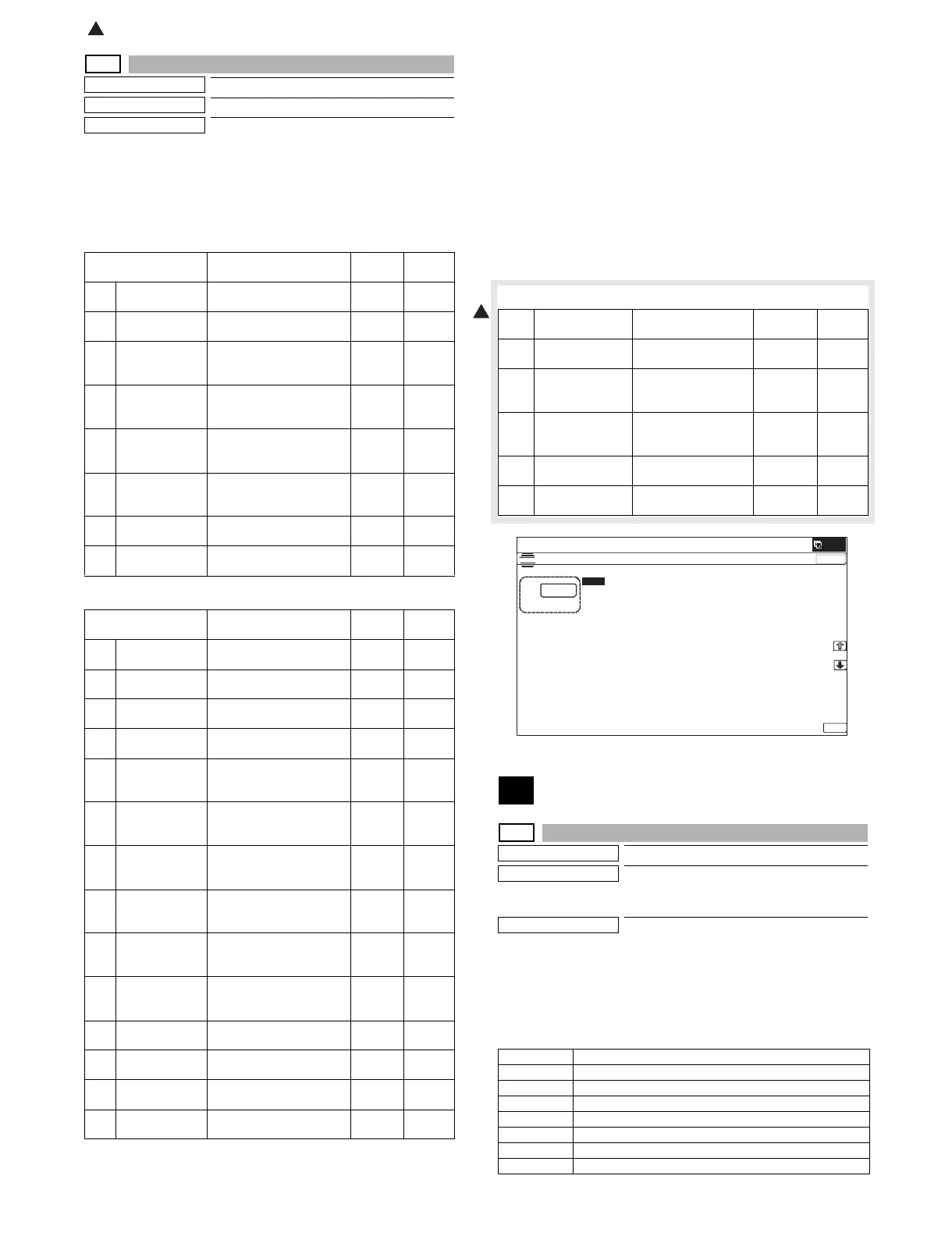

<Inner finisher>

<Saddle stitch finisher>

NOTE: "A: SADDLE POSITION (Saddle binding position adjust-

ment)" and "B: FOLDING POSITION (Saddle folding posi-

tion adjustment"

The saddle binding position adjustment and the saddle

folding position adjustment can be executed in the system

setting menu. However, the adjustments in the system set-

ting are based on the adjustment value of this simulation.

If, therefore, the adjustment value of this simulation is set

to an extreme level, the adjustment range in the system

setting may be narrowed. (Adjustment range in the system

setting ±5.0mm)

In general, when the saddle binding position and the sad-

dle folding positions are adjusted to the center by this simu-

lation, the above trouble will not occur.

<4K finisher>

4

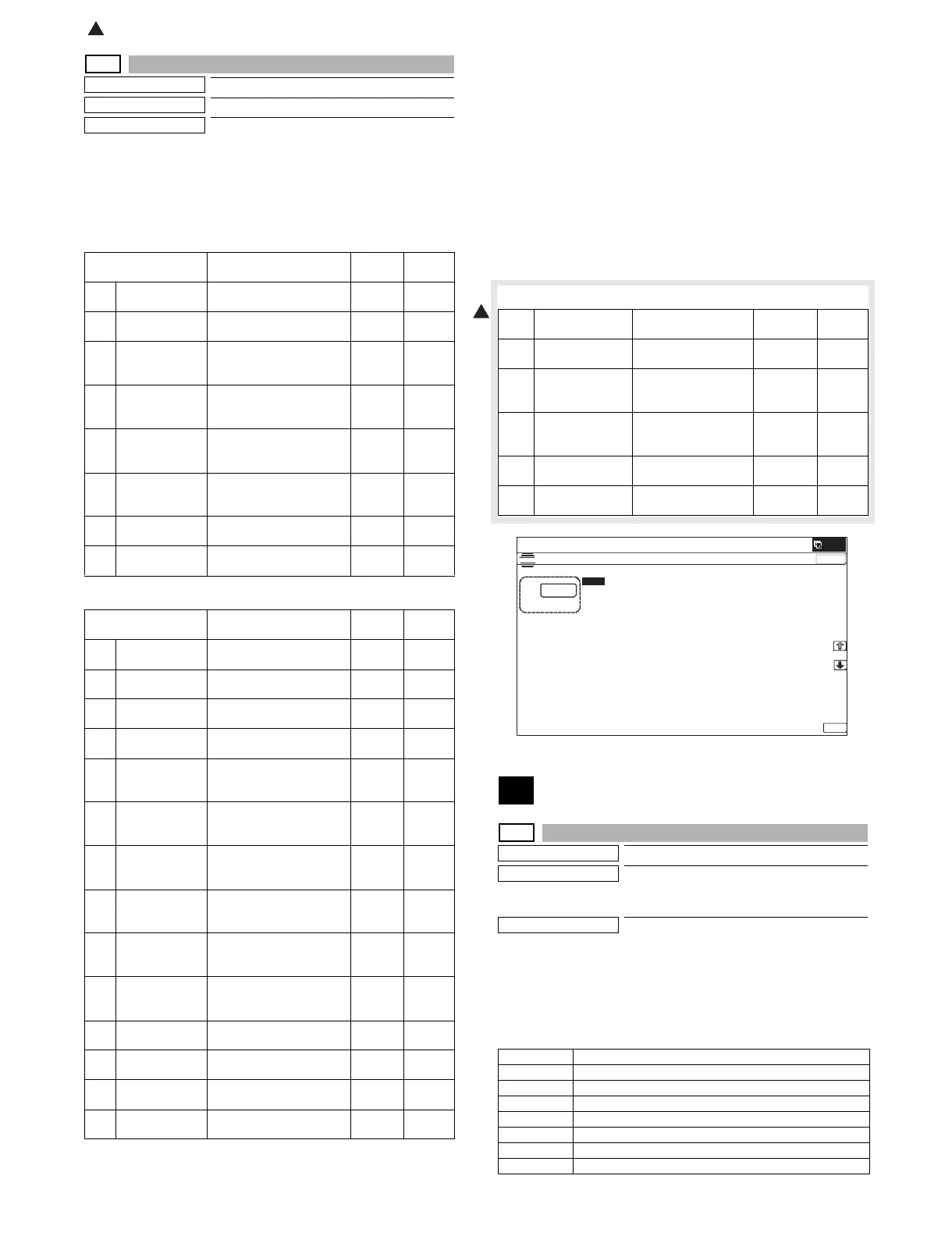

4-2

Purpose

Operation test/check

Function (Purpose)

Used to check the operations of the sen-

sors and detectors in the desk/large capac-

ity tray, and the control circuit of those.

Section

Desk/Large capacity tray (LCC)

Operation/Procedure

The operating conditions of the sensors and detectors are dis-

played.

The code names of the sensors and the detectors which are active

are highlighted.

<Desk>

Item/Display Content

Setting

range

Default

value

A FRONT

ADJUST

Alignment position

adjustment (front)

2 - 18 10

B REAR ADJUST Alignment position

adjustment (rear)

2 - 18 10

C STAPLE REAR Staple binding position

adjustment

(one position at the rear)

68 - 132 100

D STAPLE

FRONT

Staple binding position

adjustment

(one position in front)

68 - 132 100

E STAPLE BOTH Staple binding position

adjustment (center position

of two positions binding)

68 - 132 100

F STAPLE PITCH Staple binding position

adjustment (staple pitch of

two positions binding)

68 - 132 100

G PUNCH

CENTER

Punch center positioning

sensor

37 - 63 50

H PUNCH HOLE Punch hole adjustment

(paper transport direction)

42 - 58 50

Item/Display Content

Setting

range

Default

value

A SADDLE

POSITION

Saddle stitch position

adjustment

25 - 75 50

B FOLDING

POSITION

Saddle folding position

adjustment

25 - 75 50

C FRONT

ADJUST

Paper alignment position

adjustment (Front)

35 - 65 50

D REAR ADJUST Paper alignment position

adjustment (Rear)

35 - 65 50

E STAPLE REAR Staple binding position

adjustment

(one position at the rear)

25 - 75 50

F STAPLE REAR

R

Staple binding position

adjustment (one position at

the rear)

45 - 75 50

G STAPLE

FRONT

Staple binding position

adjustment

(one position in front)

25 - 75 50

H STAPLE

FRONT R

Staple binding position

adjustment (one position in

front)

25 - 55 50

I STAPLE BOTH Staple binding position

adjustment (two positions

at the center)

45 - 55 50

J STAPLE PITCH Staple binding position

adjustment (two positions

in pitch)

35 - 62 50

K PUNCH

CENTER

Punch center adjustment 35 - 65 50

L PUNCH HOLE Punch hole position

adjustment

30 - 60 50

M SADDLE_ADJU

ST_POS

Saddle alignment position

adjustment

35 - 65 50

N GRIPPER_POS Gripper exit position

adjustment

35 - 65 50

Item Display Item Set range

Default

value

A FRONT ADJUST Alignment position

adjustment (front)

0 - 20 10

B STAPLE REAR Staple binding position

adjustment (one

position at the rear)

94 - 106 100

C STAPLE FRONT Staple binding position

adjustment (one

position in front)

94 - 106 100

D PUNCH

CENTER

Punch center

adjustment

30 - 70 50

E PUNCH HOLE Punch hole position

adjustment

46 - 52 50

DCSI1 Desk 1 installation detection

DPFD1 Desk 1 transport detection

DLUD1 Desk 1 upper limit detection

DPED1 Desk 1 paper empty detection

DCSPD1 Desk 1 remaining paper quantity detection

DCSS11 Desk 1 rear edge detection 1

DCSS12 Desk 1 rear edge detection 2

DCSS13 Desk 1 rear edge detection 3

1

ǂǂǂ6,08/$7,21ǂǂ12

&/26(

7(67

),1,6+(5$'-8670(17

$˖

˷˹

˖6$''/(326,7,21

$˖

˖)2/',1*326,7,21

%˖

˖)5217$'-867

&˖

˖5($5$'-867

'˖

˖67$3/(5($55

)˖

˖67$3/(5($5

(˖

˖67$3/()5217

*˖

˖67$3/()52175

+˖

˖67$3/(%27+

,˖

˖67$3/(3,7&+

-˖

˖381&+&(17(5

.˖

˖381&++2/(

/˖

2.

: Oct. 24 2008

1

Loading...

Loading...