MX-M260/M310/M260N/M310N ADJUSTMENTS 5 - 3

6) Measure the distance H between the paper lead edge and the

image print start position. Set the image print start position set

value again.

• 1 step of the set value corresponds to about 0.127mm shift.

• Calculate the set value from the formula below.

99 – H/0.127 (mm) = Image print start position set value

<H: Print start position measurement value (mm)>

∗ Fit the print edge with the paper edge, and perform the lead

edge adjustment.

Example:99 – 5/0.127 = 99 – 39.4 = about 59

Note : FIf the set value is not obtained from the above formula, per-

form the fine adjustment.

7) Execute SIM 50-1-2 to adjust the main tray lead edge void.

• 1 step of the set value corresponds to about 0.127mm shift.

• Calculate the set value from the formula below.

B/0.127 (mm) = Lead edge void adjustment value

<B: Lead edge void (mm)>

Example: When setting the lead edge void to 2.5mm:

2.5 /0.127 = about 20

<Adjustment specification>

[H: Print start position measurement value (mm),

B: Lead edge void (mm)]

(2) RSPF image lead edge position adjustment

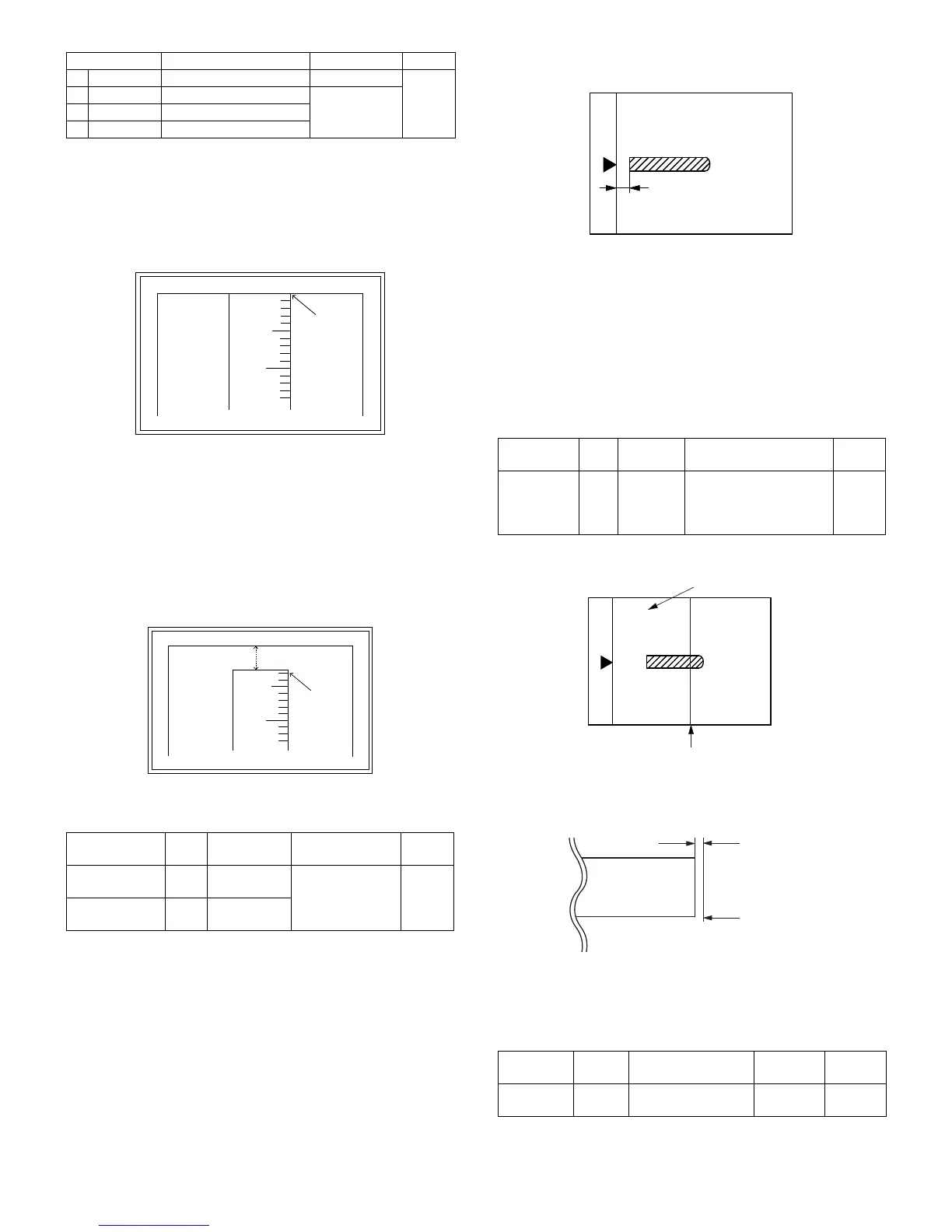

1) Set a scale on the OC table as shown below.

Note: Since the printed copy is used as a test chart, put the scale in

paralleled with the edge lines.

2) Make a copy, then use the copy output as an original to make an

RSPF copy again.

3) Check the copy output. If necessary, perform the following adjust-

ment procedures.

4) Execute SIM 50-6.

5) Set the RSPF lead edge position set value so that the same image

is obtained as that obtained in the previous OC image lead edge

position adjustment.

<Adjustment specification>

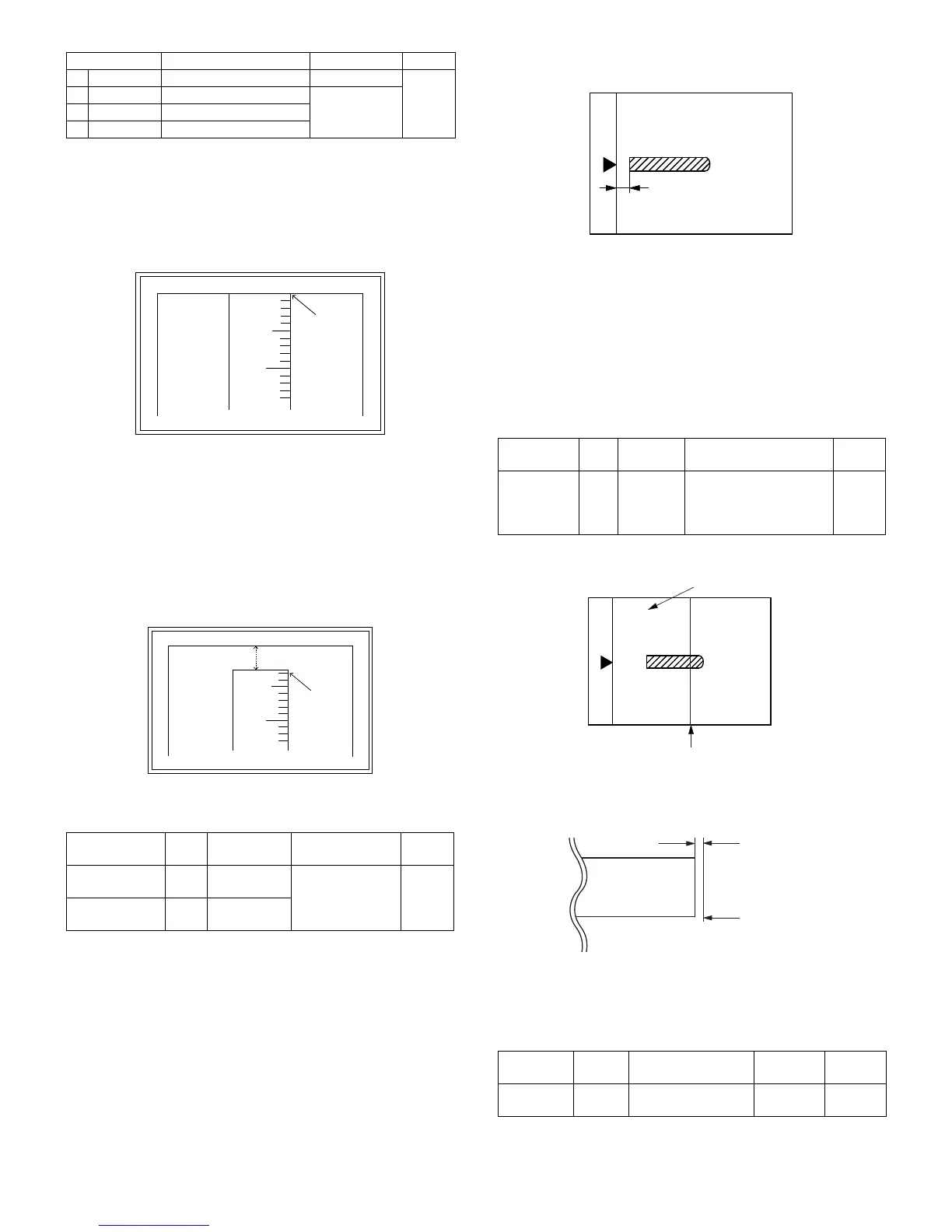

(3) Rear edge void adjustment

1) Set a scale as shown in the figure below.

2) Set the document size to A4 (8.5" x 11"), and make a copy at

100%.

3) If an adjustment is required, follow the procedures below.

4) Execute SIM 50-1 and set the density mode to DEN-B. The cur-

rently set adjustment value is displayed.

5) Enter the set value and press the start key.

The correction value is stored and a copy is made.

<Adjustment specification>

Item Content Setting range Default

1TRAY1

1st tray 0-99

53

2OPTION

Option tray

1-99

3MANUAL

Manual feed

4DUPLEX

Back print

Adjustment

mode

SIM Set value Spec value

Setting

range

Main tray lead

edge void

50-1

-2

B/0.127 Lead edge void:

1 – 4mm

Image loss: 3mm

or less

1 – 99

Print start

position

50-5 99 – H/0.127

5

10

0mm

0mm

5

10

2.5mm

2.5mm

Adjustment

mode

SIM Set value Spec value

Setting

range

RSPF

image lead

edge

position

50-6 1 step:

0.127mm

shift

Lead edge void:

1 – 4mm

Image loss: 3mm or less

1 – 99

Adjustment

mode

SIM Set value

Spec

value

Setting

range

Rear edge

void

50-1-6

1 step: 0.127mm

shift

4mm or

less

1 – 99

A4 (8.5" x 11")

Paper rear edge

Void amount (Standard value: 4mm or less)

Scale image

Paper rear edge

Loading...

Loading...