34 FLOWSIC100 Flare · Addendum to Operating Instructions · 8025365/V1-0/2020-05 · © SICK Engineering GmbH

Installation

4.6.1

Nozzles, blind flanges and seals

Nozzles are delivered with factory adaption to the nominal pipe diameter, welding bevel and

marking for nozzle alignment according to the gas flow.

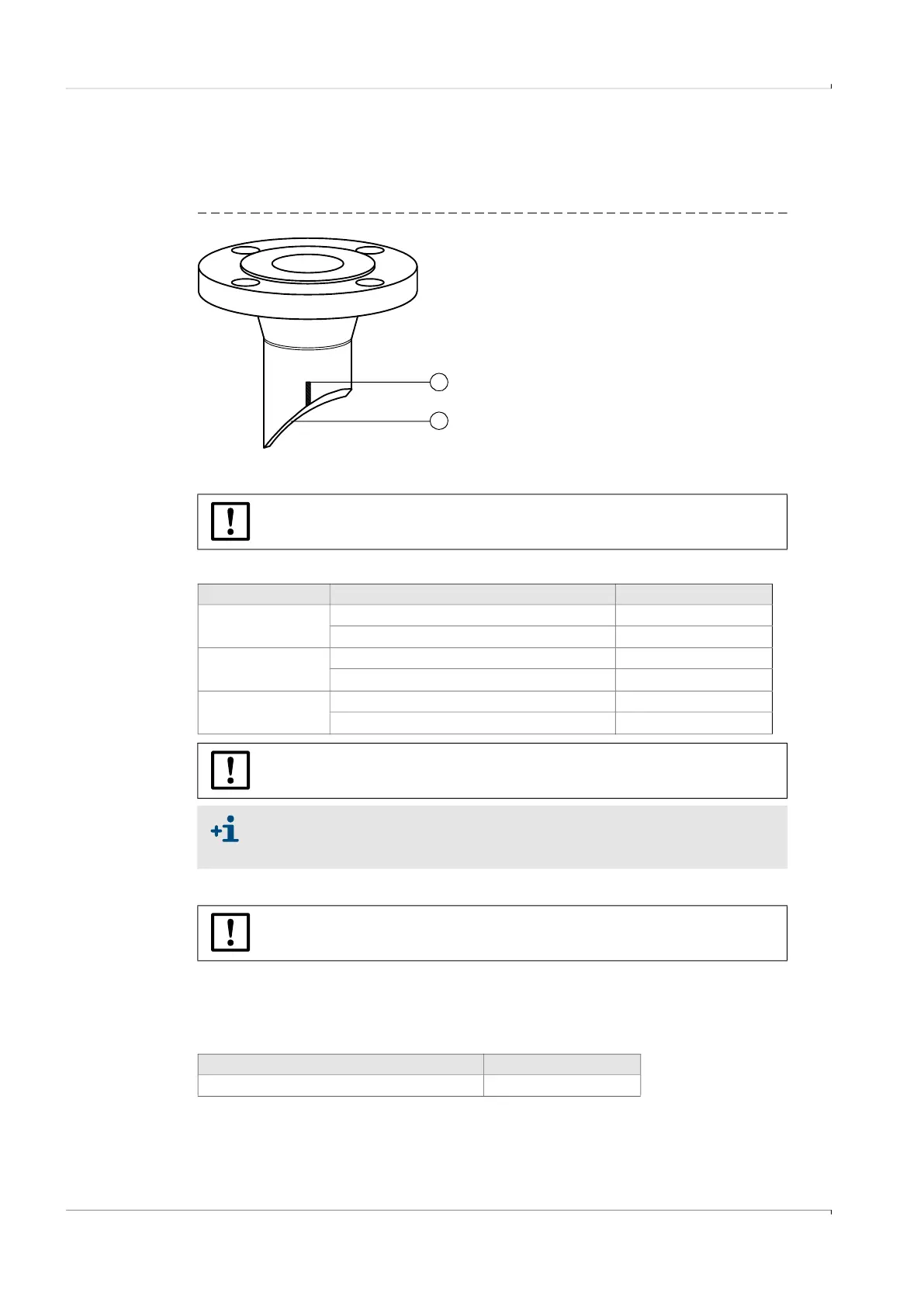

Fig. 15 Nozzle

Nozzles and blind flanges

Table 4 Available nozzles and blind flanges

Seals

Flat seals are required for the flange connection between nozzle and ball valve and

between the ball valve and the sender/receiver unit. These seals are included in the

standard scope of delivery of the ball valve and/or sender/receiver unit.

Table 5 Available seals

2

1

1 Welding bevel

2 Marking

NOTICE:

Observe the diagrams on

p. 79, §7.3.

Flange connection Material Temperature ranges

CL150

LTCS P355 QH1 / A350 LF2 -46 … +280°C

SS 1.4401, 1.4404, ASTM A182 Gr. 316, 316L

-196 … +280°C

CL300

LTCS P355 QH1 / A350 LF2 -46 … +280°C

SS 1.4401, 1.4404, ASTM A182 Gr. 316, 316L

-196 … +280°C

PN25 DN50

LTCS P355 QH1 / A350 LF2 -46 … +280°C

SS 1.4401, 1.4404, ASTM A182 Gr. 316, 316L

-196 … +280°C

NOTICE:

Observe the diagrams on

p. 79, §7.3.

To prevent galvanic corrosion between LTCS nozzles and stainless steel ball

valves, a nozzle insulation set (sealing material set with polymer seals and

screwed sleeves) is available as an accessory.

NOTICE:

Observe the diagrams on

p. 79, §7.3.

Material Temperature range

Grooved metal gasket B9A 1.4571 -196 … +280°C

Loading...

Loading...