104/213

Building Technologies Basic documentation LMV37.4... CC1P7546en

HVAC Products 11 Fan control 01.12.2009

6. Close the standardization

When standardization is successfully completed, reset parameter 641 to

0.

If standardization was not successful, parameter 641 assumes a negative value.

The value provides information on the cause of fault:

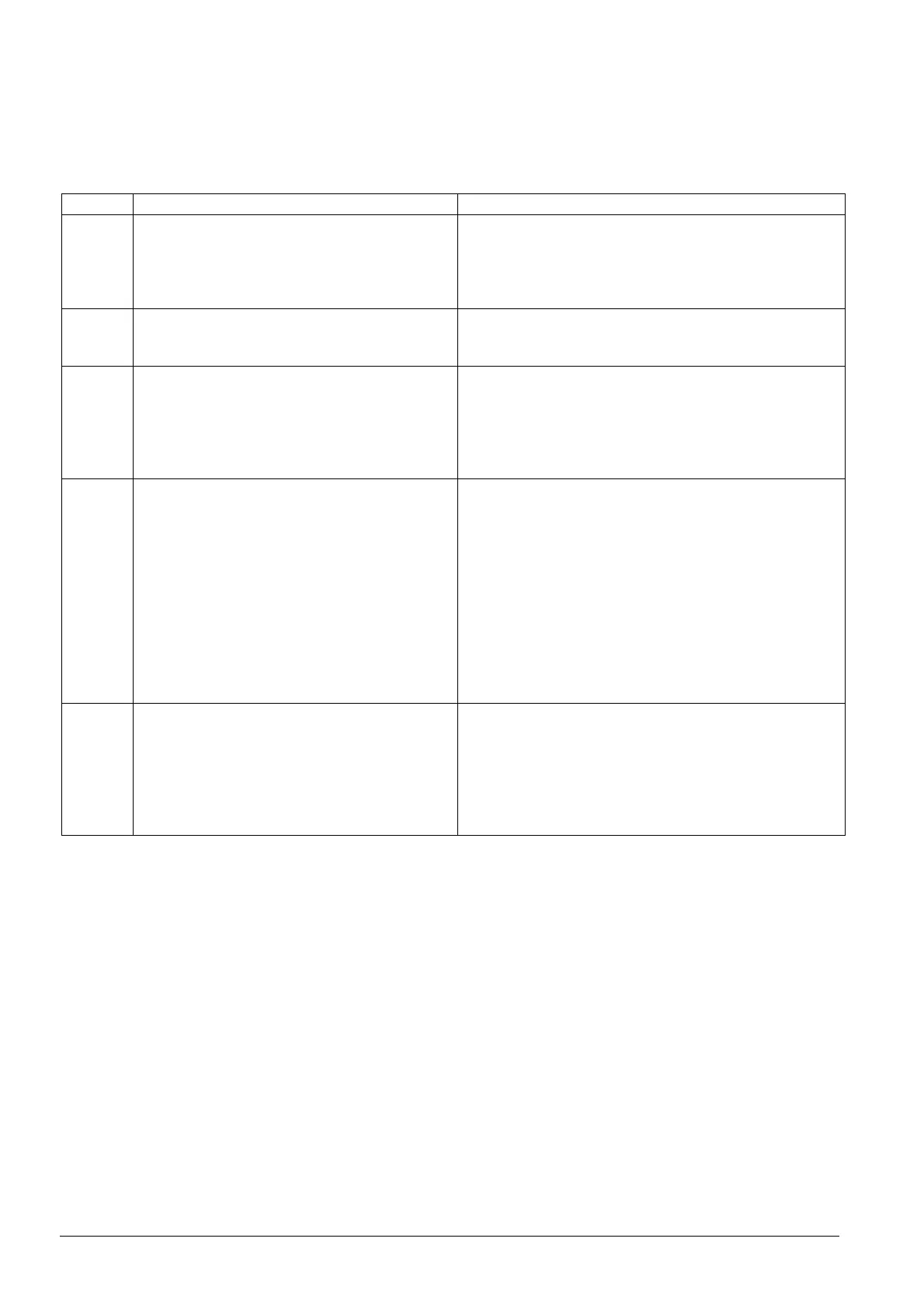

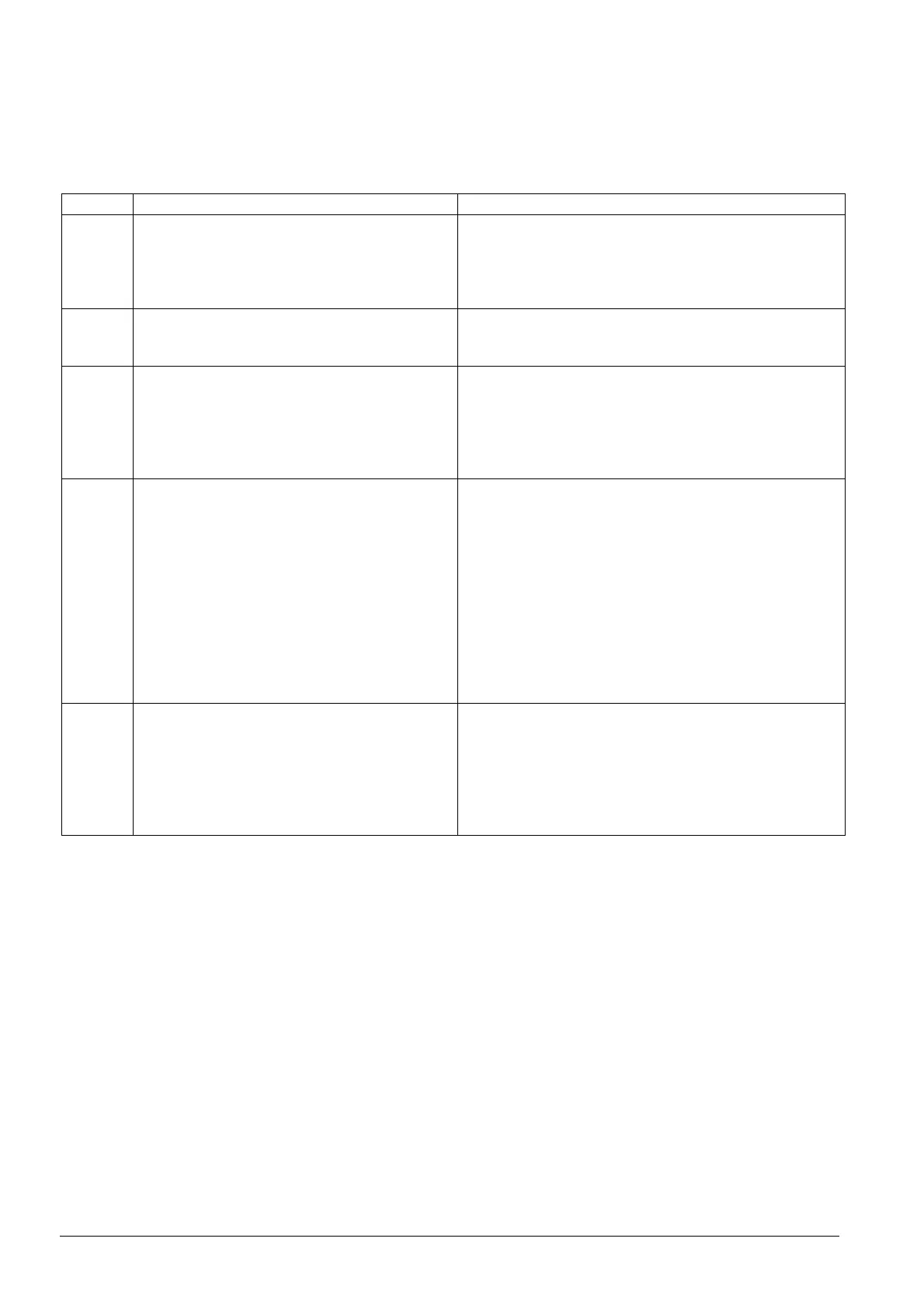

Value Error Recommended measures

-1 Timeout of standardization (VSD’s ramp

down time too long)

Timeout at the end of standardization during ramp

down of VSD.

1. VSD ramp time settings are not shorter than those

of the basic unit (parameter 523).

-2 Storage of standardized speed not

successful

Error during storage of standardized speed → lock

the basic unit and reset it again, repeat standardiza-

tion

-3 Open-circuit speed sensor

Basic unit receives no pulses from the speed sensor.

1. Motor does not turn.

2. Speed sensor is not connected.

3. Speed sensor is not actuated by the sensor disk

(check distance).

-4 Speed variation / VSD ramp up time too long

/ speed below minimum limit for standardiza-

tion

Motor has not reached a stable speed after ramp up.

1. VSD ramp time settings are not shorter than those

of the basic unit (parameters 522, 523).

2. VSD’s characteristic is not linear. Configuration of

voltage input at the VSD must accord with that of

the basic unit (DC 0…10 V).

3. VSD does not follow quickly enough the change of

the basic unit. Check VSD settings (input filter,

slippage compensation, hiding various speeds).

4. Speed of VSD lies below the minimum for

standardization (650 1/min).

-5 Wrong direction of rotation

Motor’s direction of rotation is wrong.

1. Motor turns in the wrong direction

→ change

parameterization of the direction of rotation or inter

change 2 live conductors.

2. Sensor disk is fitted the wrong way

→ turn sensor

disk.

Loading...

Loading...