Designing a Sequential Control System based on the Example of a Drill

S7-GRAPH for S7-300/400 Programming Sequential Control Systems

C79000-G7076-C526-01

3-5

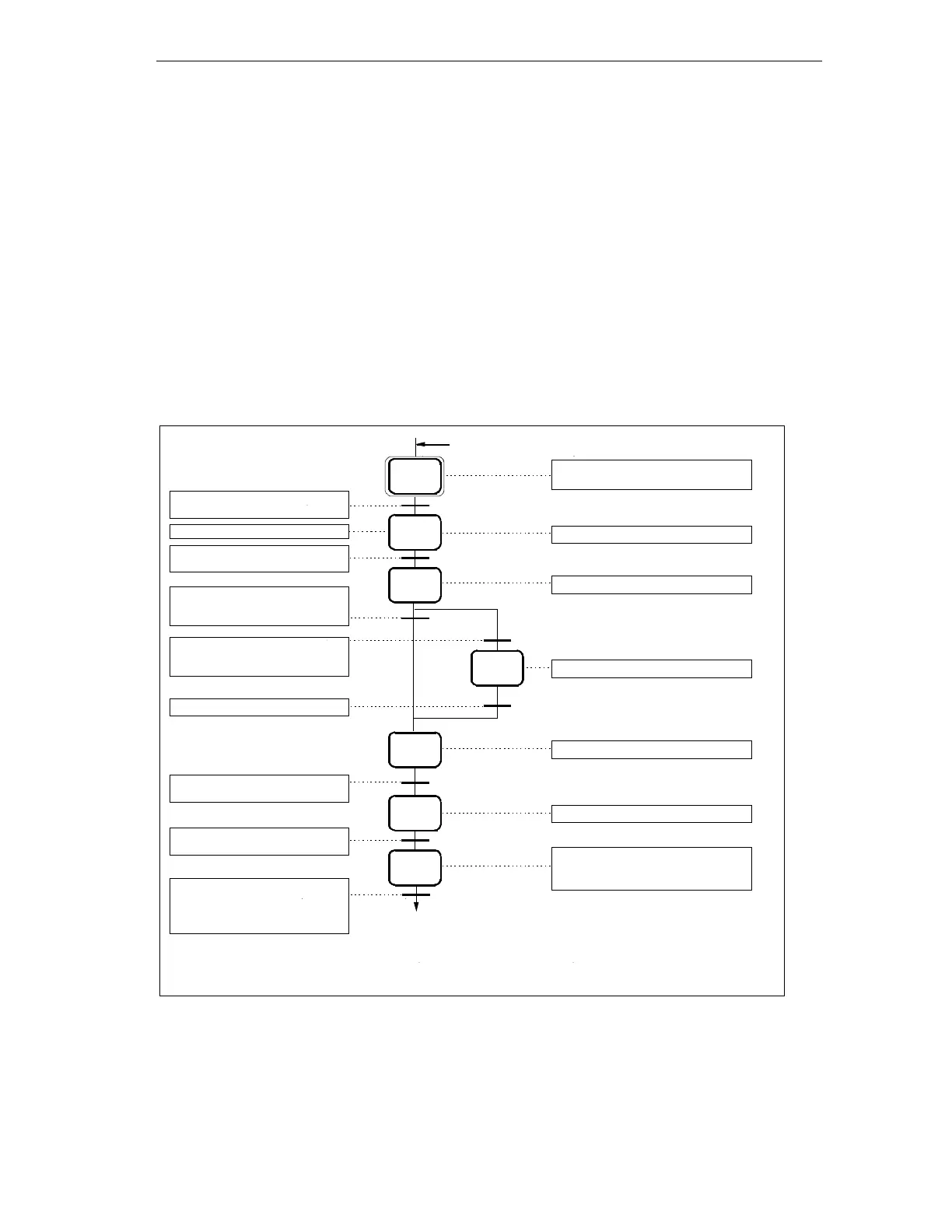

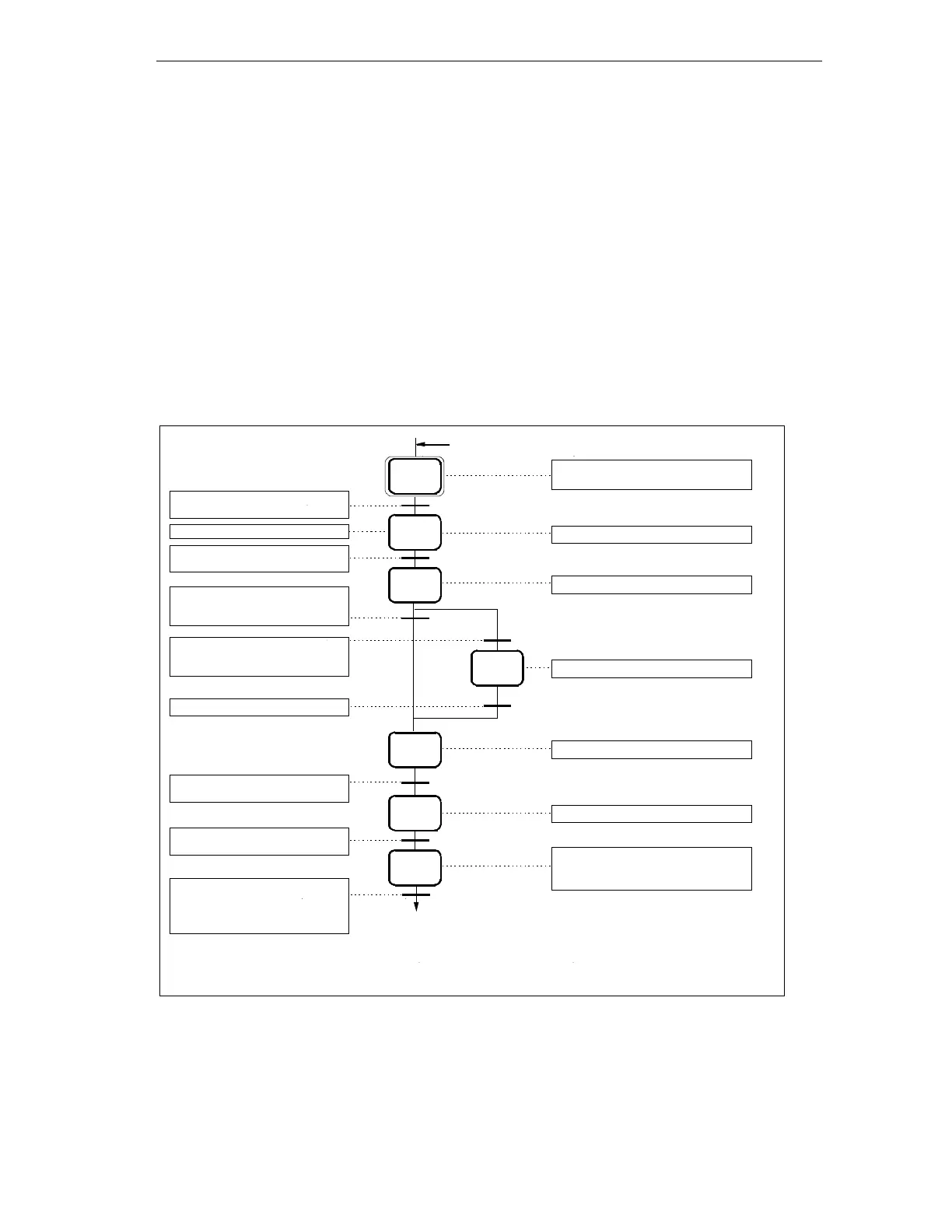

Dividing the Drilling Process into Individual Steps - Structure of the Sequencer

The drilling process is described by S7-Graph in the form of a sequencer. A

sequencer represents a sequence of single steps and conditions that control how

the process moves on to the next single step. To specify the structure of the

sequencer, follow the steps outlined below:

1. Break down the drilling process into steps and specify the order of the steps (for

example “step S2 follows S1" or “step S3 follows either step S4 or S7").

2.

For each step, specify the actions that must be performed in the step (for

example in S1 the action “Drill ready" or in S3 the action “Turn on drill motor").

3.

Then decide for every step which conditions must be met so that the process

can move on to the next step (for example for T1 the condition “Drill started -

start button pressed" or for T5 the condition “Drill in upper position").

T2

S2

T8

T3

T7

S3

S1

T4

T1

T6

S7

S4

Drill ready (initial step)

Clamp work piece

Turn on drill motor

Turn on cooling pump

Lower drill (start drilling)

Drill program started (start button

pressed)

Work piece clamped with selected

pressure

Drill motor running at selected speed

(without coolant)

Coolant pressure reached

Drill in lower position

Drill motor running at selected speed

(with coolant)

S5

S6

T5

T6

S1

Raise drill

Release work piece, turn off drill motor

and cooling pump

Drill in upper position

Work piece is released, cooling

pump stopped, drill motor stopped

Waiting time 500 ms

S = step

T = transition

Monitor clamping

Loading...

Loading...