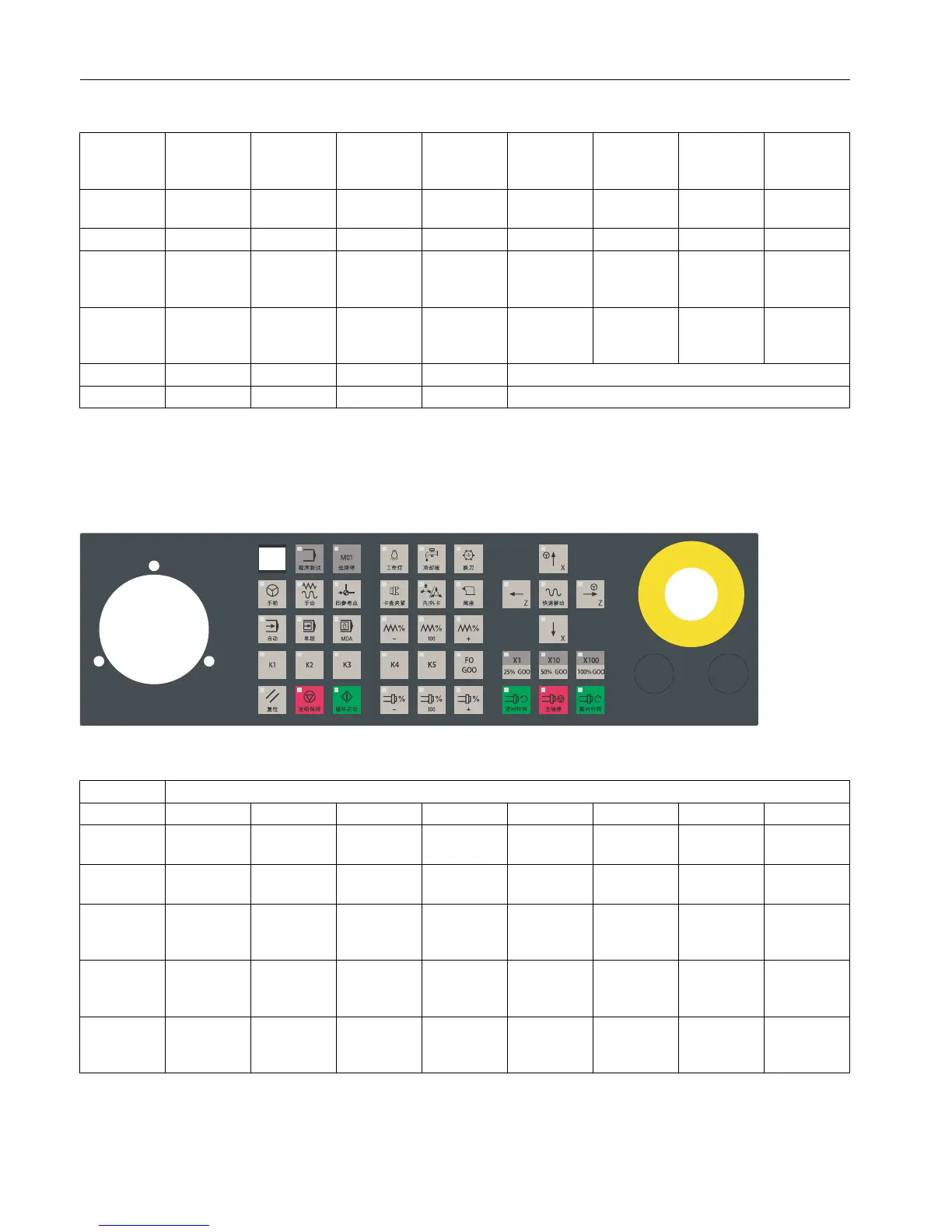

0 M01 PRO‐

GRAM

TEST

MDA SINGLE

BLOCK

AUTO REF.

POINT

JOG HAND

WHEEL

1 Key 7 TAIL

STOCK

INT. EXT. CHUCK TOOL

CHANGE

COOLANT LAMP ROV

2 100 (INC) 10 (INC) 1 (INC) Key 12 Key 11 Key 10 Key 9 Key 8

3 Axis tra‐

versing key

(↑x)

Key 13 CYCLE

START

CYCLE

STOP

RESET SPINDLE

RIGHT

SPINDLE

STOP

SPINDLE

LEFT

4 Key 21 Axis tra‐

versing key

(↓x)

Key 19 Axis tra‐

versing key

(→z)

RAPID Axis tra‐

versing key

(←z)

Key 15

8 1

1)

1

1)

7 SEG LED1

2)

9 1

1)

1

1)

7 SEG LED2

2)

1)

To ensure the correct display of the active tool number, make sure that you set Bit 4 and Bit 5 to 1.

2)

You can set only values 0 to 9 for each 7-segment LED (LED1 and LED2).

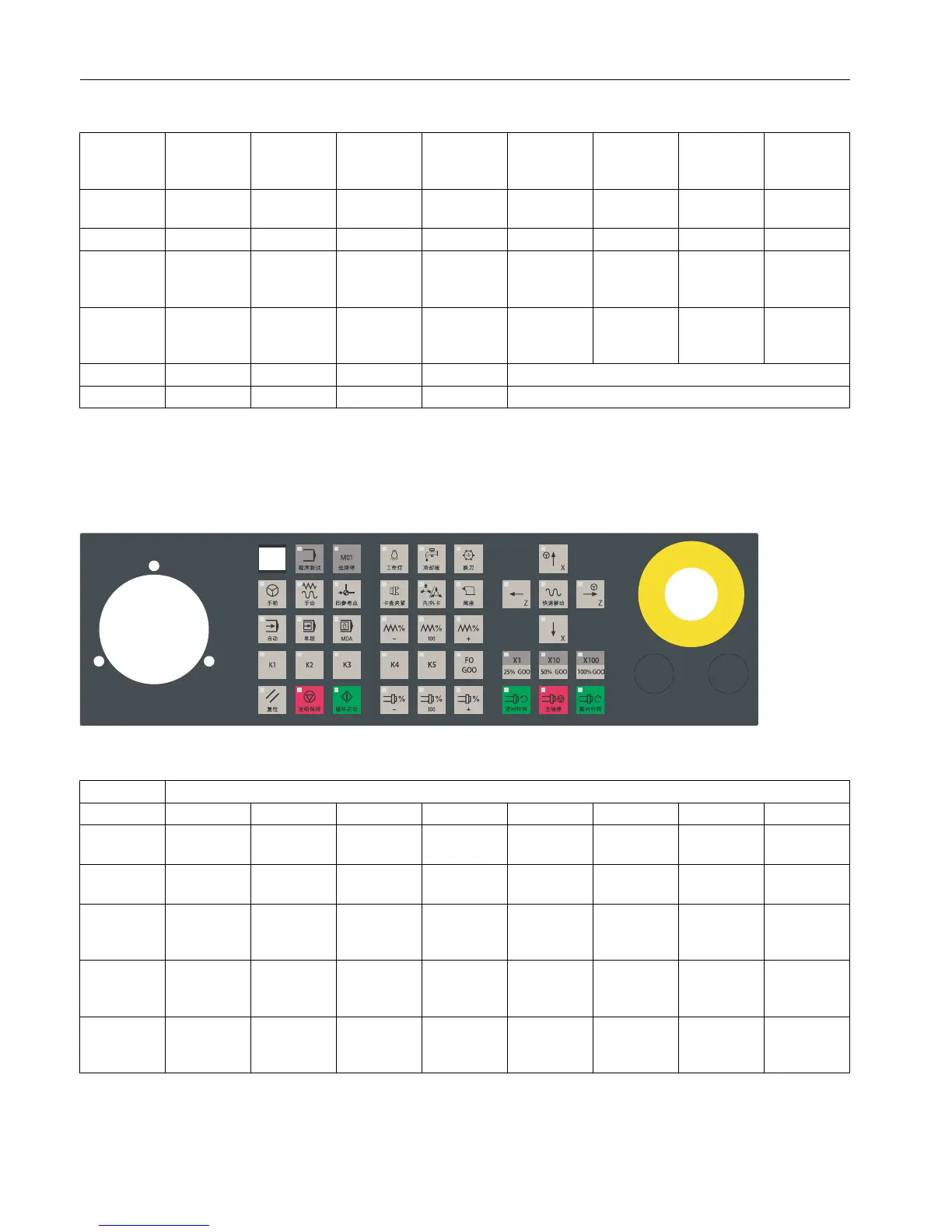

Horizontal MCP with a reserved slot for the handwheel

From the MCP

DB1000 From the MCP [r]

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Key 2 Key 1 MDA SINGLE

BLOCK

AUTO REF. POIN

T

JOG HAND

WHEEL

1 Feed over‐

ride key (-)

TAIL

STOCK

INT. EXT. CHUCK TOOL

CHANGE

COOLANT LAMP Key 3

2 100 (INC) /

100% G00

10 (INC) /

50% G00

1 (INC) /

25% G00

F0 G00 Key 5 Key 4 Feed over‐

ride key (+)

Feed over‐

ride key

(100%)

3 Axis tra‐

versing key

(↑x)

Spindle

override

key (-)

CYCLE

START

CYCLE

STOP

RESET SPINDLE

RIGHT

SPINDLE

STOP

SPINDLE

LEFT

4 M01 PRO‐

GRAM

TEST

Axis tra‐

versing key

(↓x)

Spindle

override

key (+)

Axis tra‐

versing key

(→z)

RAPID Axis tra‐

versing key

(←z)

Spindle

override

key (100%)

PLC user interface

6.2 Signals from/to the MCP

Parameter Manual

474 List Manual, 01/2017

Loading...

Loading...