57

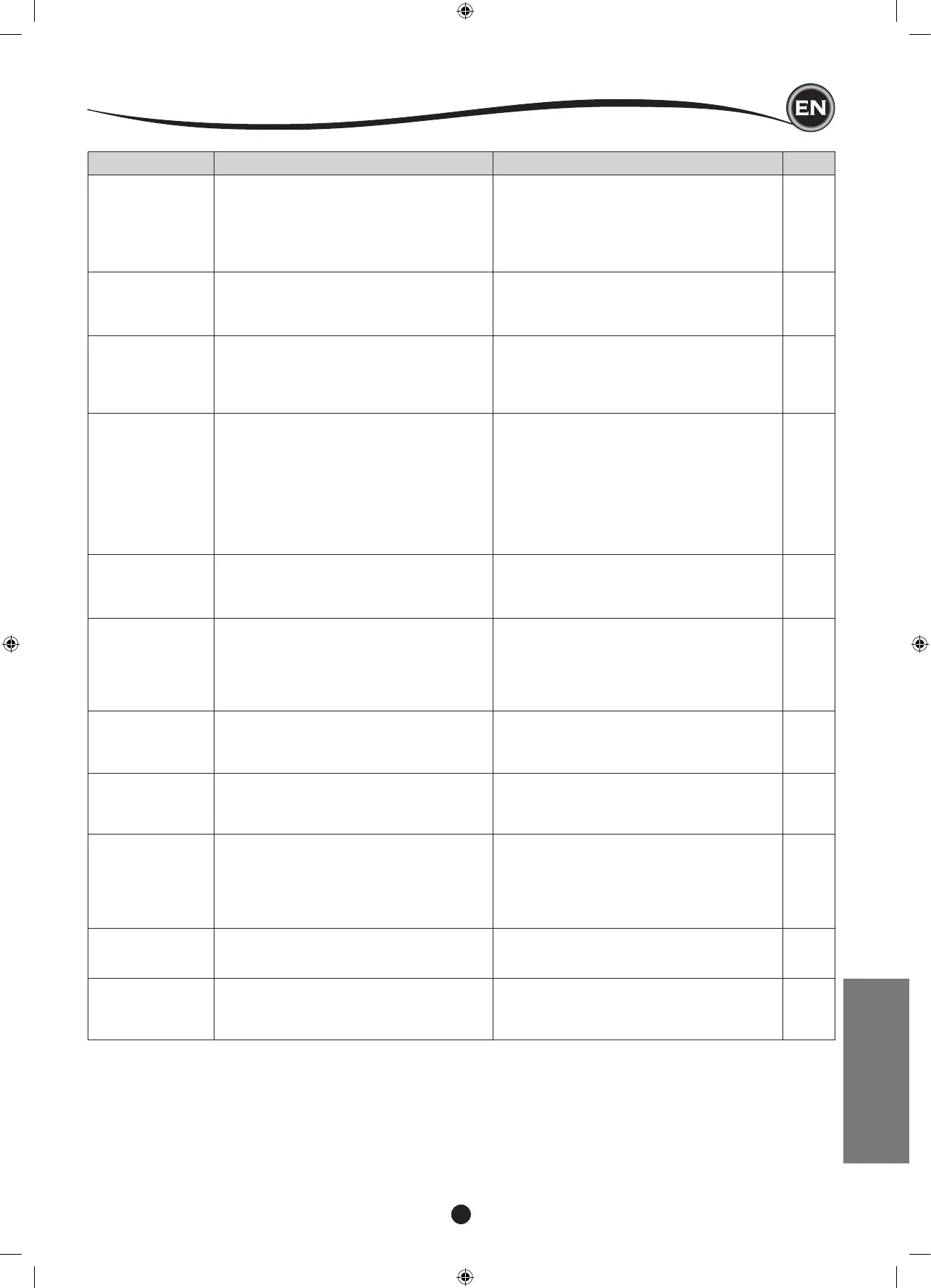

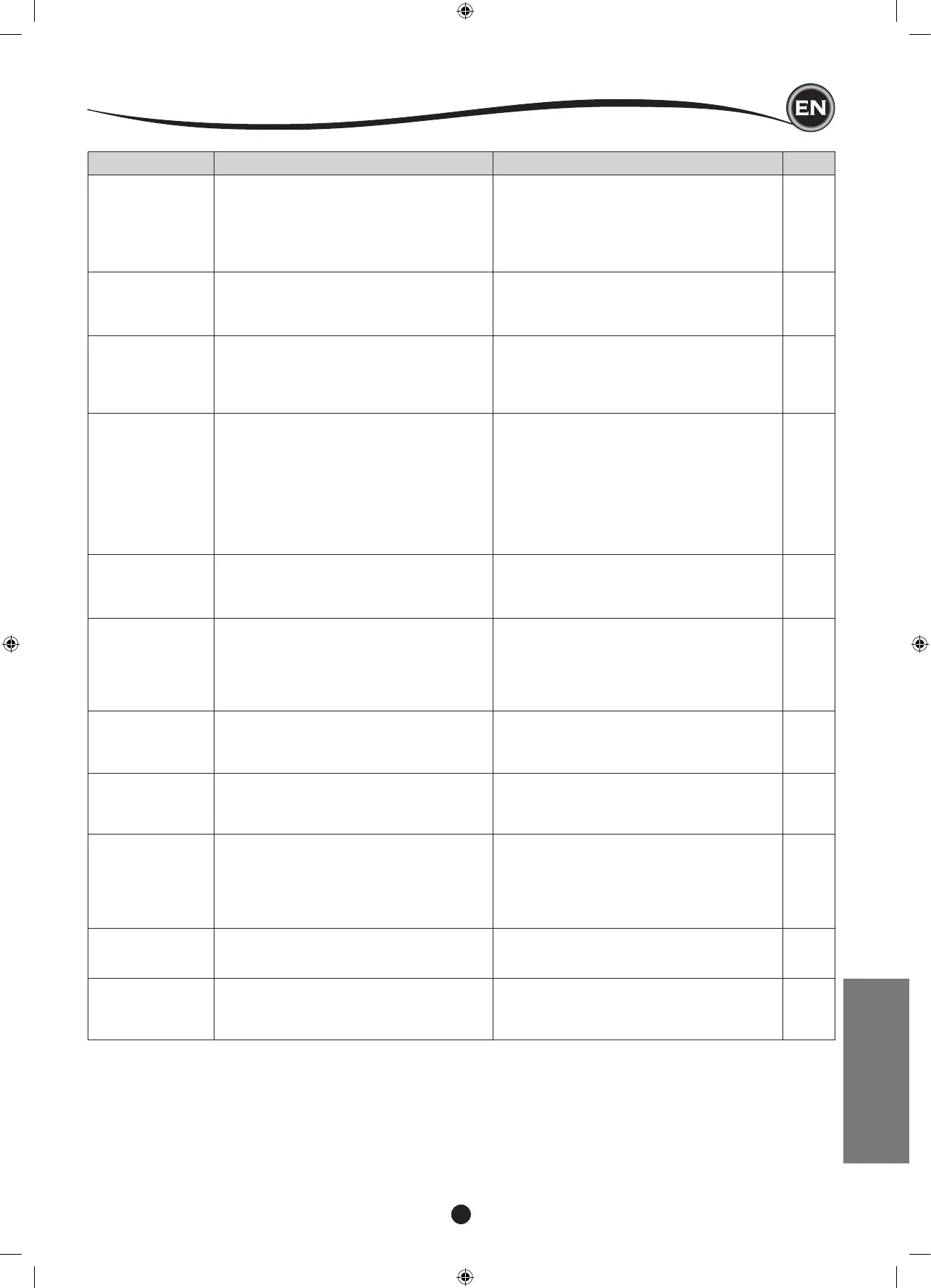

MAINTENANCE

PROBLEM

Upper thread

breaks

Lower thread

breaks

Machine skips

stitches

Fabric puckers

Machine makes

loose stitches or

loops

Stitch pattern is

distorted

Threader does not

thread to needle

eye

Machine does not

feed properly

Needle breaks

Machine runs with

difculty

Machine will not

run

CORRECTION

Re-thread machine.

Remove entwined thread.

Re-insert needle.

Readjust thread tension.

Choose correct thread.

Re-thread the bobbin.

Rewind the bobbin.

Clean the holder.

Re-insert needle.

Insert new needle.

Choose correct size needle for fabric.

(use stretch needle)

Re-thread machine.

Re-thread the bobbin.

Insert new needle.

Readjust thread tension.

Select less dense design for fabric, or change

fabric type.

Use proper stabilizer for fabric being

embroidered.

Re-thread the bobbin.

Re-thread machine.

Readjust thread tension.

Attach correct foot.

Remove obstruction.

Adjust the thread tension.

Use proper stabilizer for fabric being

embroidered.

Raise the needle.

Re-insert needle.

Insert new needle.

Raise the feed dogs.

Regulate stitch length.

Clean the feed dog area.

Do not pull fabric.

Select correct foot and pattern.

Re-insert needle.

Choose correct size needle and thread.

Remove the needle plate and bobbin holder

and clean the hook race.

Insert plug fully into outlet.

Turn on the switch.

Lower the foot.

CAUSE

Machine not properly threaded.

Thread entwined around bobbin.

Needle inserted incorrectly.

Thread tension too tight.

Thread of incorrect size or poor quality.

Bobbin threaded incorrectly.

Bobbin wound unevenly or too full.

Dirt or lint in the bobbin holder.

Needle inserted incorrectly.

Bent or blunt needle.

Incorrect size of needle.

(on stretch fabric)

Machine not properly threaded.

Bobbin threaded incorrectly.

Blunt needle.

Thread tension too tight.

Design too dense for fabric being

embroidered.

Insufcient stabilizer.

Bobbin threaded incorrectly.

Machine not properly threaded.

Tension not adjusted properly.

Presser foot is not suited for the pattern.

Hoop or carriage is interferred.

Thread tension is not balanced.

Insufcient stabilizer.

Needle is not raised to highest position.

Needle inserted incorrectly.

Bent needle.

Feed dogs are lowered.

Stitch length not suitatble for fabric.

Lint and dust accumulated around feed dog.

Fabric pulled while sewing.

Needle is hitting the presser foot.

Needle inserted incorrectly.

Incorrect size needle or thread for fabric

being sewn.

Dirt or lint accumulated in the hook race and

feed dog.

Cord not plugged into electrical outlet.

Power switch is not turned on.

Presser foot is not lowered.

Page

19

18

9

14,43

9,45

18

17

56

9

9

9,45

19

18

9

14,43

48

45

18

19

14,43

8

52

14,43

45

20

9

9

12

14

56

21

24-

9

9,45

56

10

10

11

Loading...

Loading...