MAINTENANCE

1323RD&1623RD Operation Manual 9-3 © Mar. 2022

3. Duplicate the Repair & Inspection Report template

for each inspection. Store the completed tables for

10 years or until the machine is no longer in use or

as required by machine owner/company/custodian.

4. Use the following table to record the results. After

each section is complete, mark the appropriate box.

5. If any inspection results are marked as "NO", the

machine must be stopped and re-inspected after

repair is completed and the box marked "-

REPAIRED" shall be checked. Select the

appropriate inspection procedure based on the

inspection type.

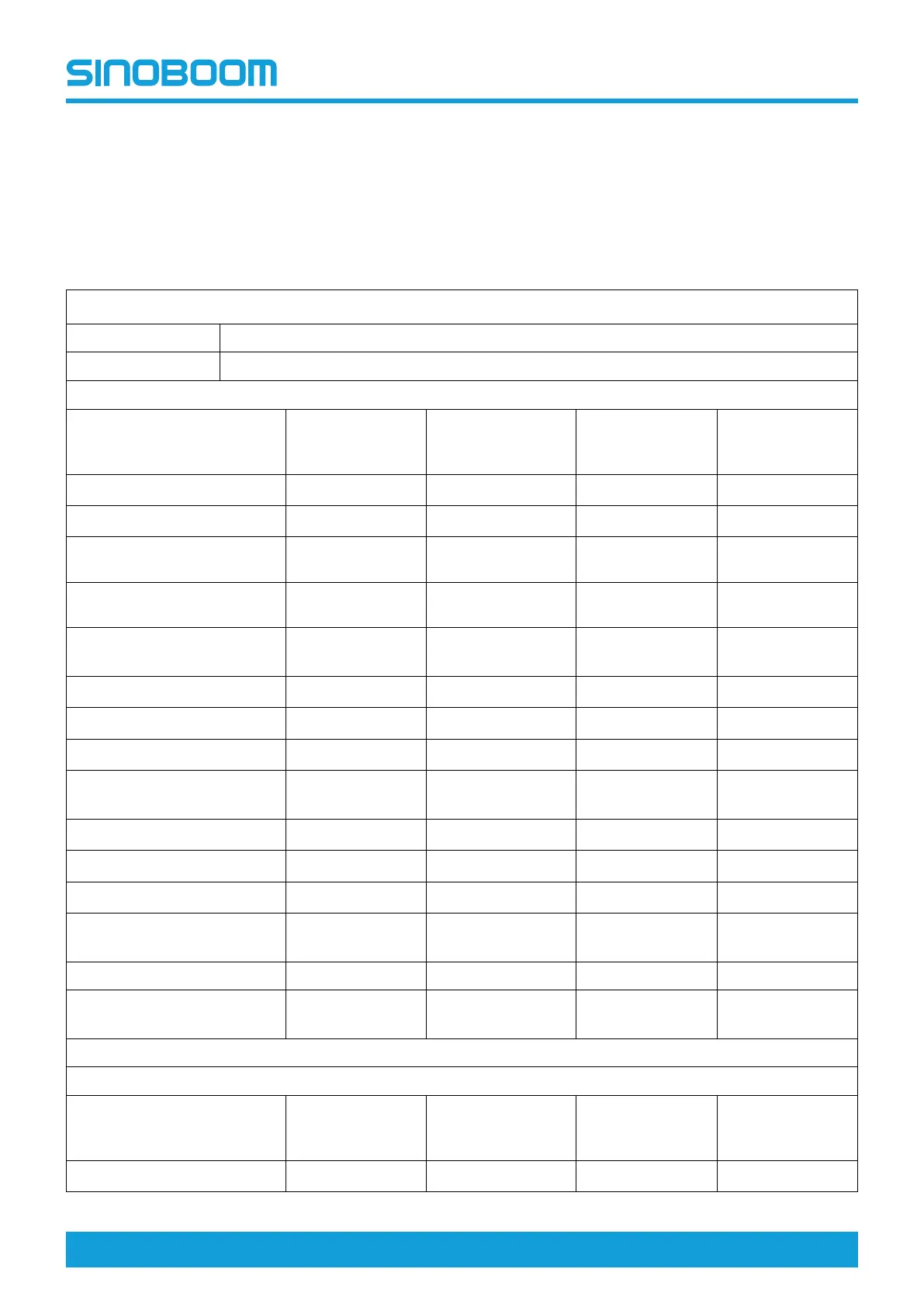

Table 9-3

REPAIR & INSPETION REPORT

Model

Serial No.

Checklist A Procedures

Items

YES/Machine is

in Good

Condition

NO/Machine Has

Damage or

Malfunction

REPAIRED/

Machine Has

Been Repaired

Problem

Description

A-1 Inspect All Manuals

A-2 Inspect All Decals

A-3 Inspect Damaged, Loose

or Lost Parts

A-4 Inspect Hydraulic Oil

Level

A-5 Inspect Hydraulic Oil

Leakage

A-6 Inspect Fuel Level

A-7 Inspect Fuel Leakage

A-8 Inspect Engine Oil Level

A-9 Inspect Engine Intake

System

A-10 Inspect Engine Belt

A-11 Inspect Fuel Filter

A-12 Inspect Cooling Fan

A-13 Inspect Coolant Level

(Water-cooled Engine)

A-14 Functional Tests

A-15 Perform Maintenance

after 30 Days

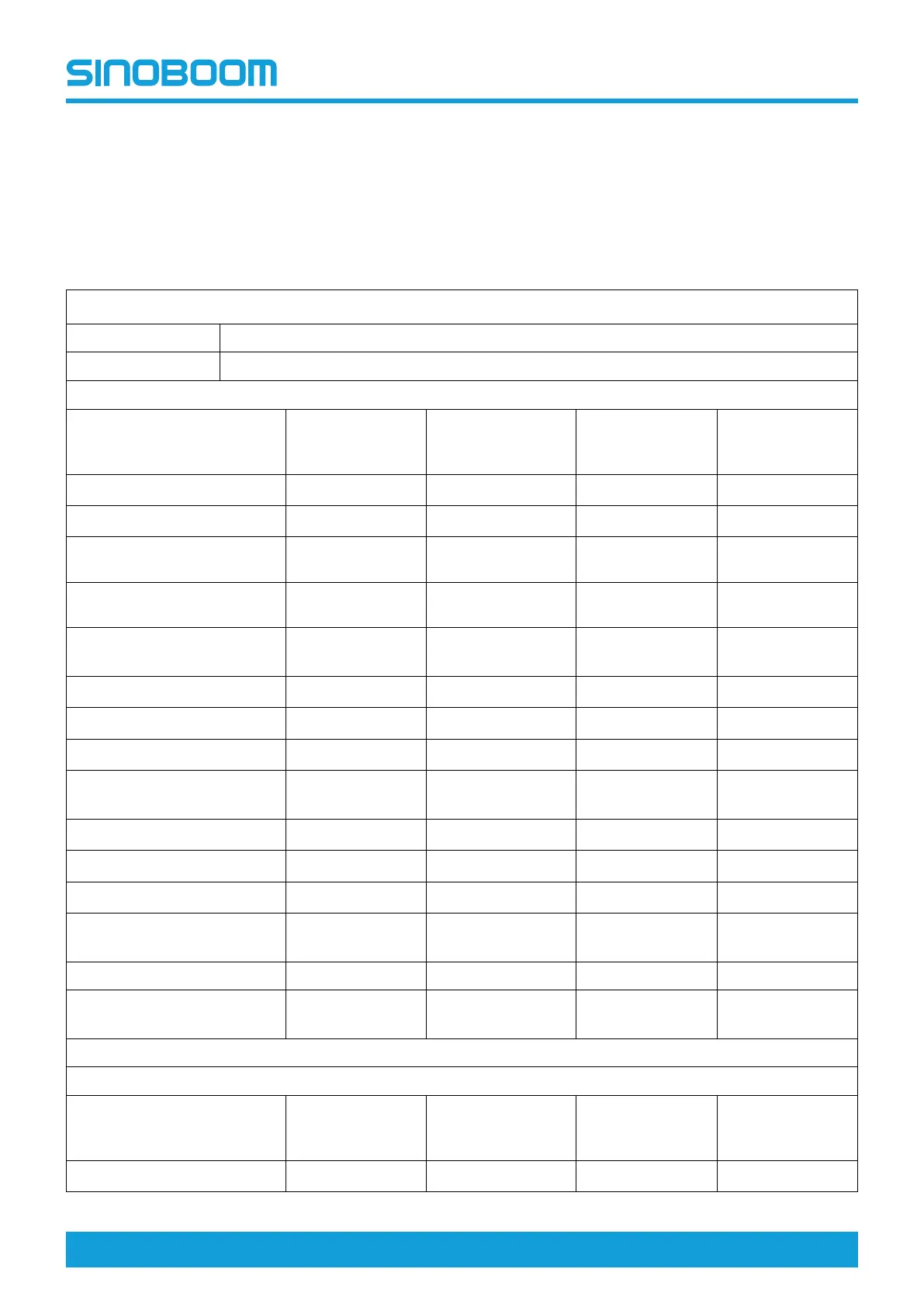

Checklist B Procedures

Items

YES/Machine is

in Good

Condition

NO/Machine Has

Damage or

Malfunction

REPAIRED/

Machine Has

Been Repaired

Problem

Description

B-1 Inspect Electrical Wiring

Loading...

Loading...