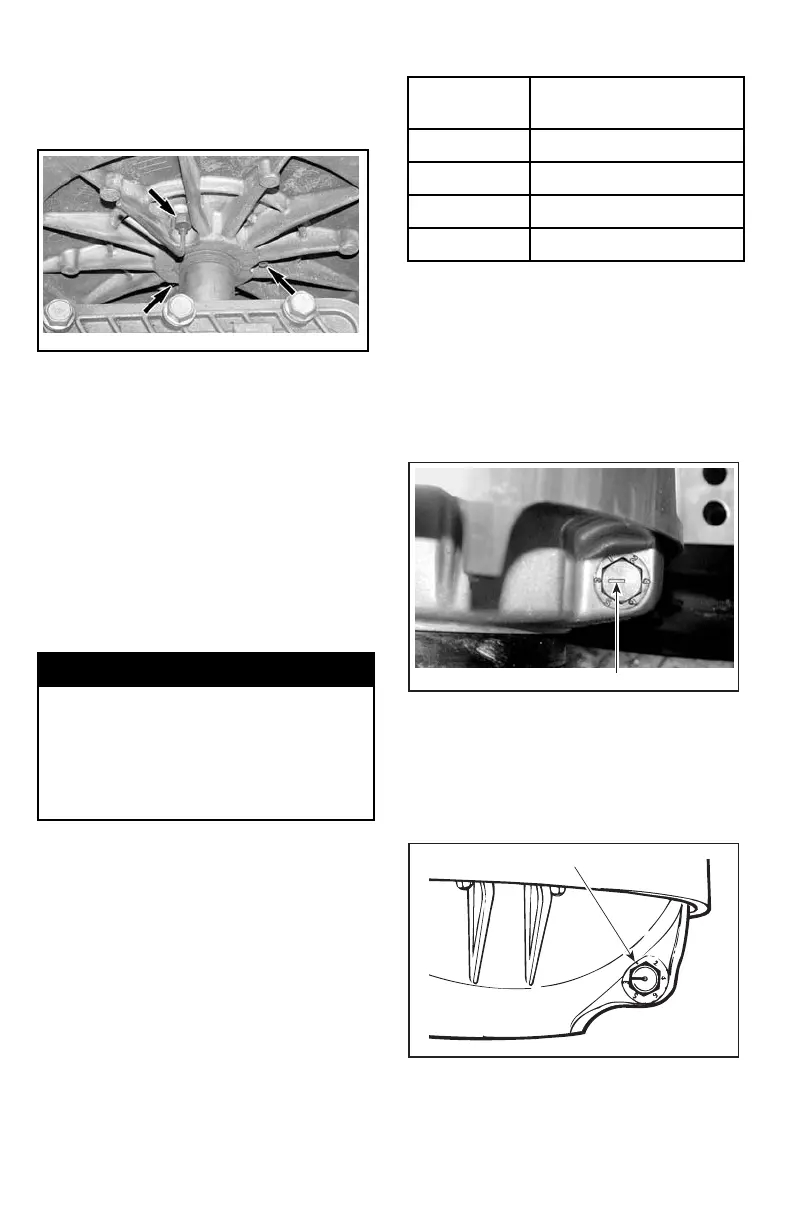

Adjust drive belt height using Allen

screws. Loosen jam nuts then turns

Allen screws.

mmr2007-201-006_a

– To lower belt in driven pulley: turn

Allen screws clockwise.

– To raise belt in driven pulley: turn

Allen screws counterclockwise.

NOTE: Turn Allen screws 1/4 turn at a

time, then rotate driven pulley to allow

drivebelttosettleinpulley. Check

height, repeat as required.

NOTE: Allen screws must be re-

strained while tightening jam nut to

prevent throwing adjustment out.

Drive Pulley Adjustment

WARNING

Remove tether cord cap (DESS

key) before performing any main-

tenance or adjustment, unless

otherwise specified. Vehicle must

be parked in a safe place, away

from the trail.

The drive pulley is factory calibrated to

transmit maximum engine power at a

predefined RPM. Factors such as am-

bient temperature, altitude or surface

condition may vary this critical engine

RPM thus affecting snowmobile effi-

ciency.

This adjustable drive pulley allows set-

ting maximum engine RPM to main-

tain maximum power.

Calibration screws should be adjusted

so that actual maximum engine RPM

matches the maximum horsepower

RPM.

ENGINE

MAXIMUM

HORSEPOWER RPM

550F 6900 RPM (± 100)

600 7000 RPM (± 100)

600 HO SDI 8000 RPM (± 100)

V800 7250 RPM (± 100)

NOTE: Use precision digital tachome-

ter for engine RPM adjustment.

NOTE: The adjustment has an effect

on high RPM only.

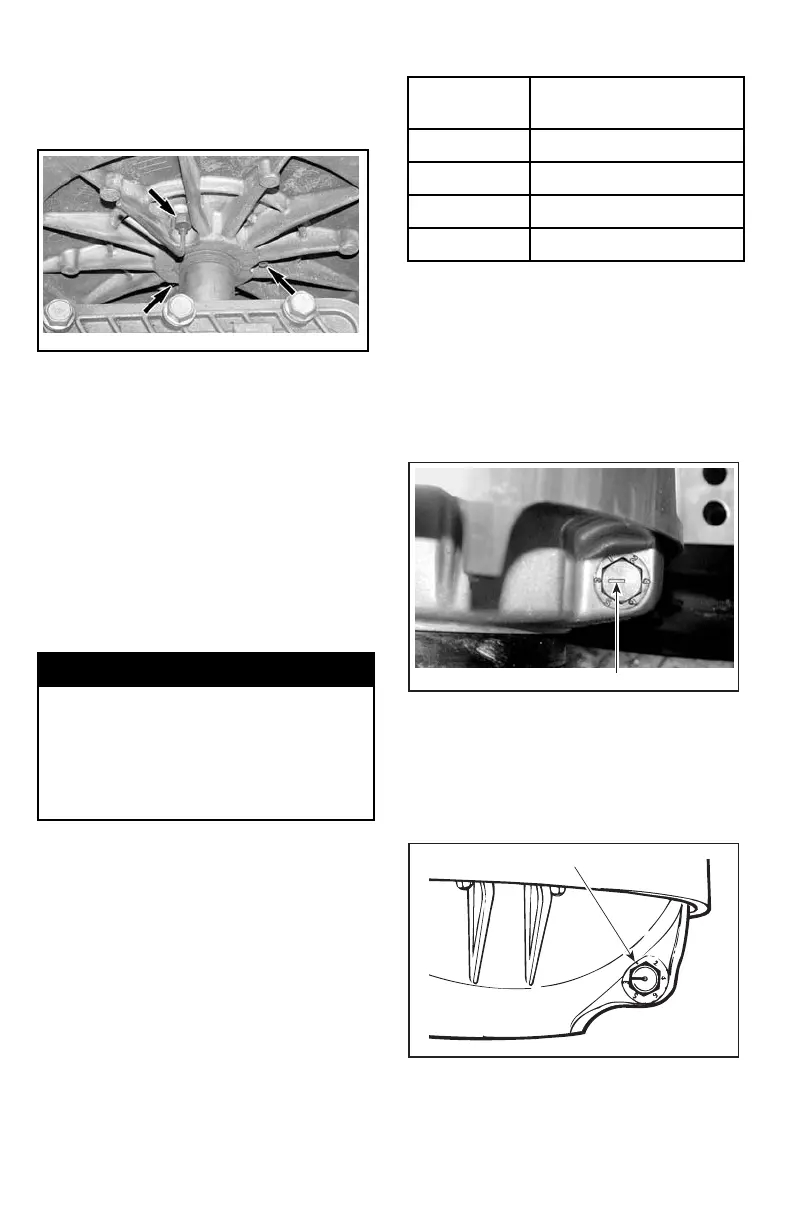

To adjust, turn calibration screws.

Calibration screw has a notch on top

of its head.

1

A33D19A

TYPICAL

1. Notch

There are 6 positions numbered 1 to

6. On TRA drive pulley, note that in

position 1 the number is substituted

by a dot (due to its location on casting).

A16D0GA

1

TYPICAL — TRA DRIVE PULLEY

1. Position 1 (not numbered)

102

_____________________

Loading...

Loading...