SECTION 2, Page 11SJKB-40-D, SJKB-40-D/F

JUN. 1999

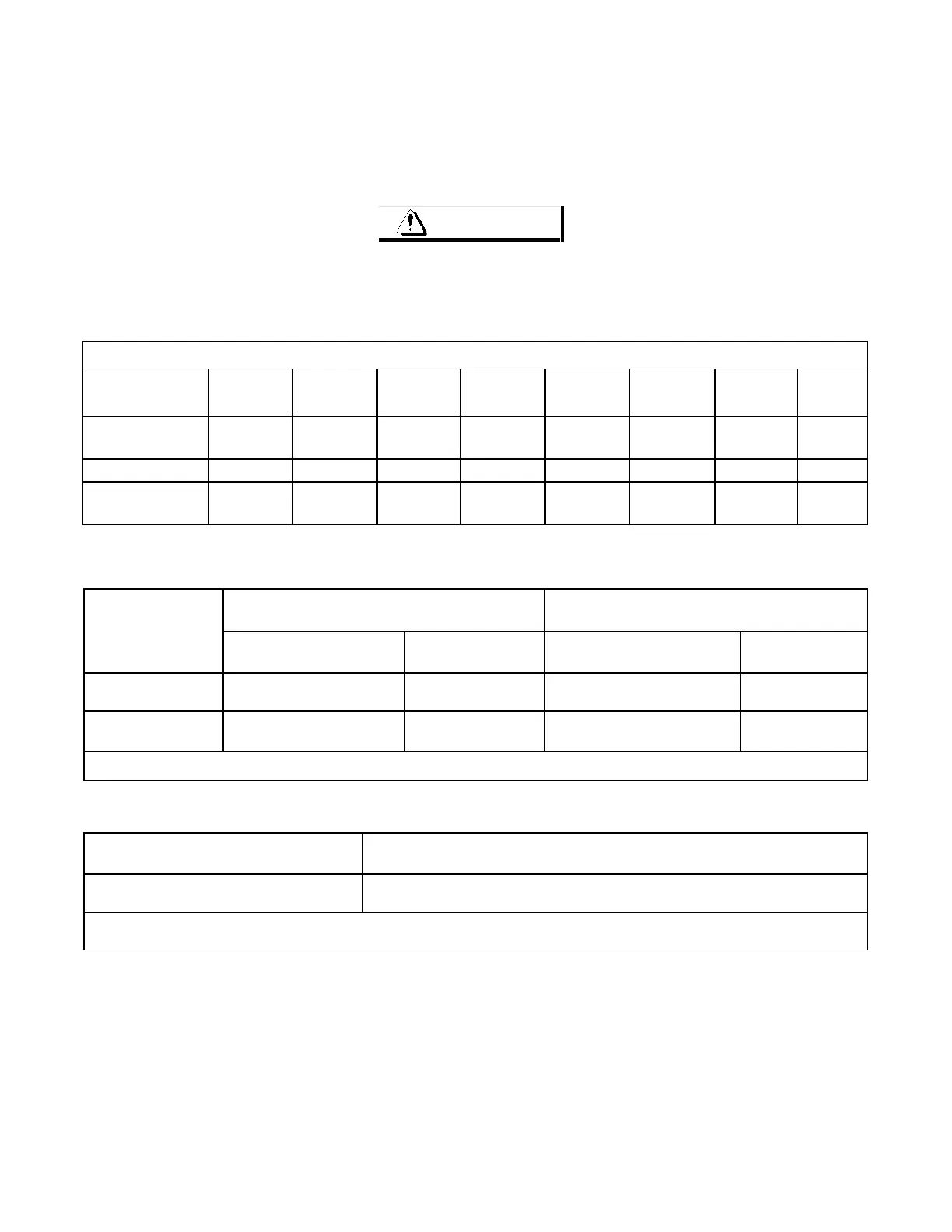

Table 2-2. Owners Annual Inspection Record

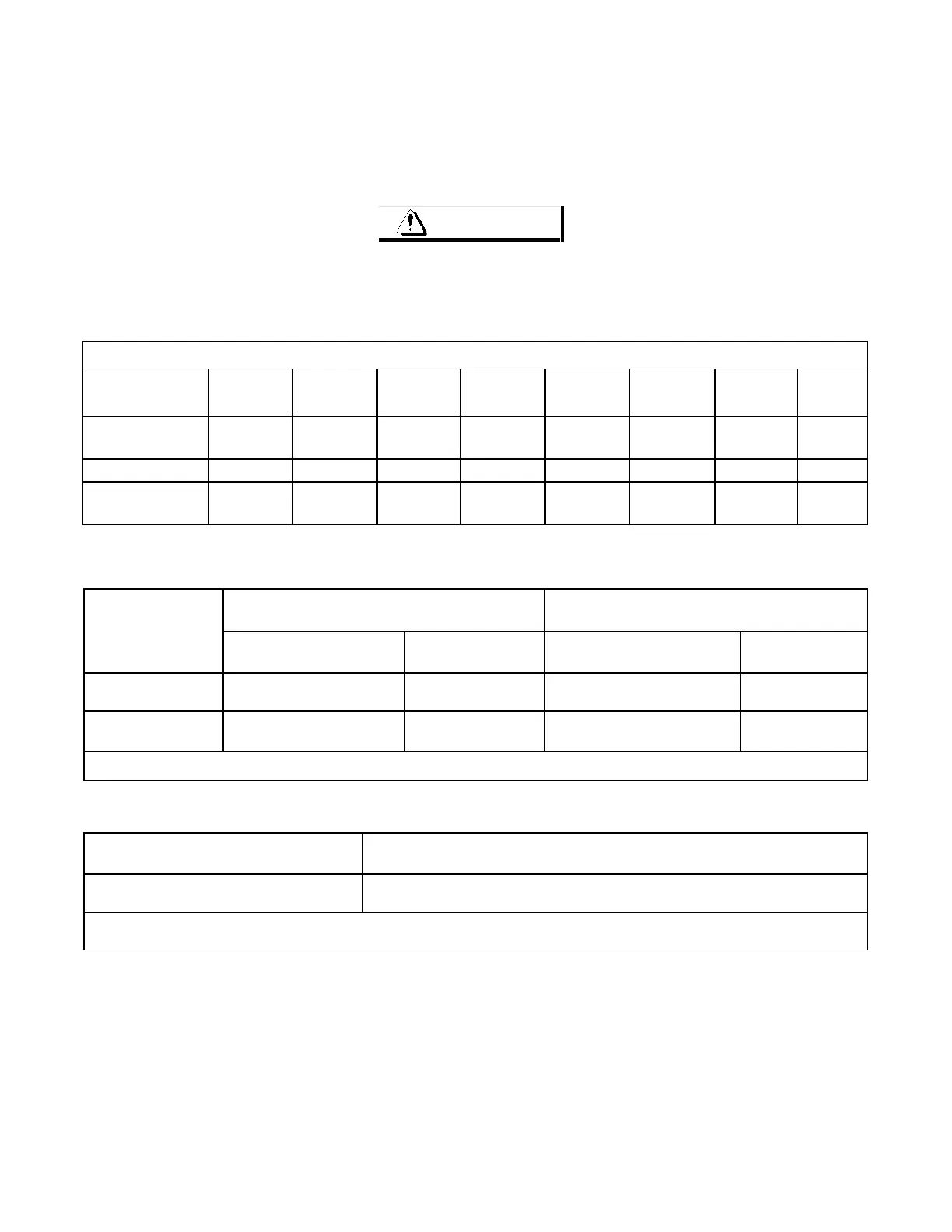

Table 2-3. Tire Specifications

Table 2-4. Maximum Platform Capacities

RECOMMENDED HYDRAULIC OILS

DO NOT use synthetic or fire resistant oil in this work platform. Use ATF Dexron III (ESSO) or equivalent hydraulic oil.

For conditions causing oil temperatures below -31°F (-35° C) and above 122°F (50° C) consult Skyjack, Inc.

Mt40c-201

Mt40c-202

Mt40c-203

RECOMMENDED AXLE LUBRICANT

TWO WHEEL DRIVE: SAE 80W90 GL-5 gear oil.

FOUR WHEEL DRIVE: Sunoco duragear (synthetic) SAE 75W90 gear oil or equivelant.

BRAKE OPERATION TEST PROCEDURE

Proper operation of the parking brakes should be checked daily or at the beginning of each shift. Locate the machine

in an appropriate area for testing the brakes. IMPORTANT NOTE: The area for testing the machine MUST be completely

level and free of obstructions. DO NOT drive on an incline unless the parking brakes are working properly. With the

machine fully stowed and the throttle switch in the high position (if engine powered). Drive the machine forward at full

speed and remove foot from foot switch. Repeat this step driving in reverse.

WARNING

Parking brakes will instantly engage causing the machine to stop immediately.

The machine should come to an instant and abrupt stop. If the machine does not stop instantly or if the machine pulls

to one side while stopping, the brake adjustment MUST be checked before putting the machine into service.

MODEL NUMBER___________________________ SERIAL NUMBER______________

RECORDING

DATE

RECORDING

YEAR #

1 2 3 4 5 6 7 8

OWNERS NAME

INSPECTED

BY

Model

Tire Fill Specification

Size Rating Type Pressure

STANDARD 30 x 10.00 x 16.5 10 Ply Air 55 psi

FOAM FILLED

(Option)

30 x 10.00 x 16.5 10 Ply Solid Urethane *

* 28 Durometer Fill installed at 55 psi.

Model Platform Capacity (unrestricted)

SJKB-40-D, SJKB-40-D/F 500# (227kg) 2 occupants

NOTE: Refer to capacity label on work platform for additional information.

Loading...

Loading...