Page 28

SECTION V ELECTRICAL SYSTEM TROUBLESHOOTING

5-1. Troubleshooting Notes

The basic operation of each component will be

defined along with a drawing and explanation on

how to check it out.

Certain defective components could cause the

entire table to stop functioning or only one control

function to stop. It would depend on what part of the

component failed. Other defective components

would only cause one control function to stop.

The following defective components could cause

all control functions to be affected:

a. Motor/Pump Assembly (starting capacitor)

b. Main Switch Circuit and Wiring

The following defective components could cause

all control functions to be affected or only one

control function:

a. Relay Box

b. Pendant Control

The component listed below would only affect one

control function:

Solenoid

When troubleshooting an electrical circuit, start at

the problem and work back to the power source.

5-2. Main Switch

The main power supply, 120 VAC, 60 HZ, comes in

through the power cord and through the main

switch. The main switch opens both lines when in

the "OFF" position. Two 10 amp fuses are used to

protect the complete electrical system and are

located next to the main switch.

a. Main Switch Test

The following test will determine if line voltage is

applied to connector CN4, which in turn would

power the table.

1. Plug the power cord into the 120VAC power

supply (wall receptacle) and turn ON the main

switch.

2. Disconnect connector CN4 from the relay

box. See figure 5-1. Leave all other connectors

connected.

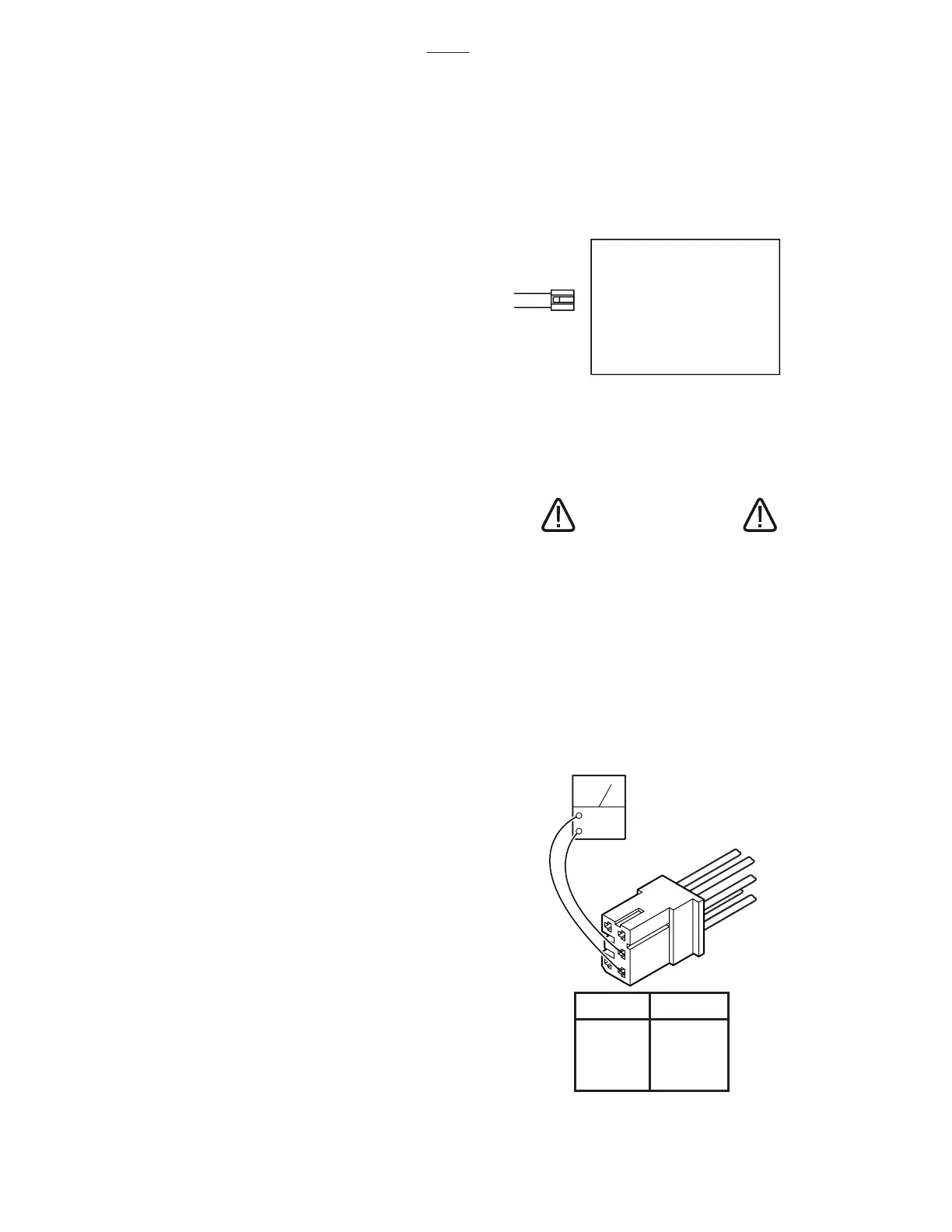

Figure 5-2. Connector CN4

Figure 5-1. Main Power Test

CAUTION

Line voltage (120 VAC) will be mea-

sured in this test. Do not touch uninsu-

lated connector pins or meter test leads.

3. Use an AC voltmeter capable of measuring

120 VAC and measure the voltage between pins

1 and 2 (black and white wires) located in connec-

tor CN4. See figure 5-2. You should receive line

voltage 120 VAC.

3500

CN4

RELAY BOX

PIN NO. COLOR

1 White

2 Black

3Red

4 Blue

5 Yellow

ACV

5

4

1

2

3

Loading...

Loading...