Page 52

NOTE

If the pump has been activated continu-

ously for 1-1/2 to 2 minutes, the thermal

protector will interrupt the power to the

pump.

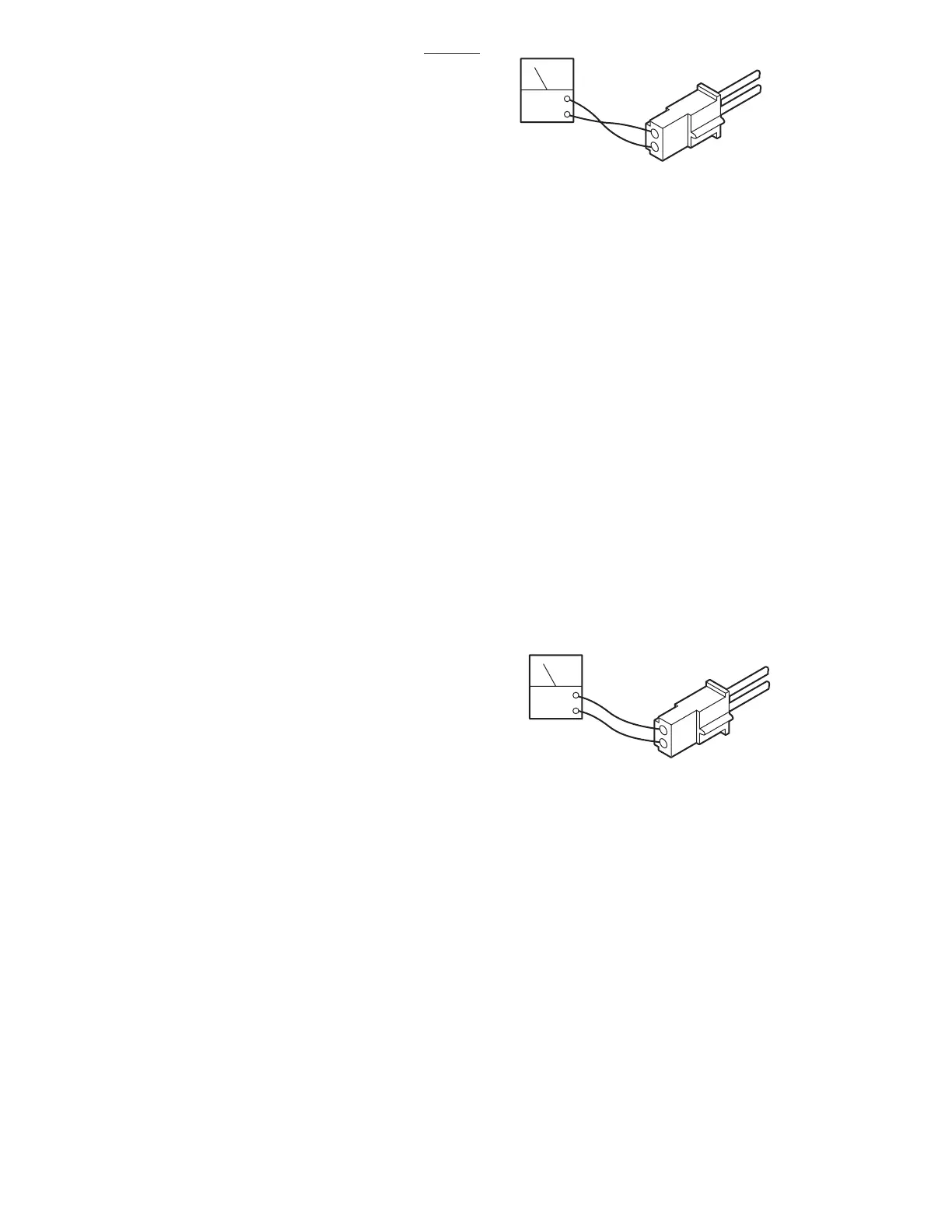

b. Thermal Protector Test

The Thermal Protector is built in to the pump motor

and is used to interrupt the current flow to the pump

motor to protect it from possible damage due to

overheating.

1. Turn OFF both BATTERY and AC120V

operating modes.

2. Use an ohmmeter to test for continuity

between terminals 1 and 2 on the connector CN16.

See figure 6-22.

d. Test #2

The solenoid can be checked out using an ohm-

meter R x 1 scale.

1. Measure the resistance between the two

pin connector in question as shown in figure 6-20.

Connector must be disconnected. Polarity of

meter leads is not important.

2. The meter should read approximately 16

ohms at room temperature.

3. Measure the resistance between either pin

and ground.

4. Meter should read infinity.

e. Test Results:

If the solenoid does not check out with the meter,

it is more than likely defective and must be

replaced.

NOTE

Whenever there are several compo-

nents of the same type, a defective

unit can also be detected by substi-

tuting a known good unit or wire con-

nector. In some cases this may be

faster than using a multi-meter.

6-12. Motor/Pump Assembly

The hydraulic pump motor is a 24 volt DC electric

motor. The oil pump unit is attached to the bottom

of the motor and is a gear type displacement

pump with a pumping capacity of .4 liter per min.

The Motor/Pump Assembly is mounted on insula-

tors in the base of the table.

a. Motor/Pump Test

1. Disconnect motor connector CN15. Leave

all other connectors connected and activate either

BATTERY or AC120V operating mode.

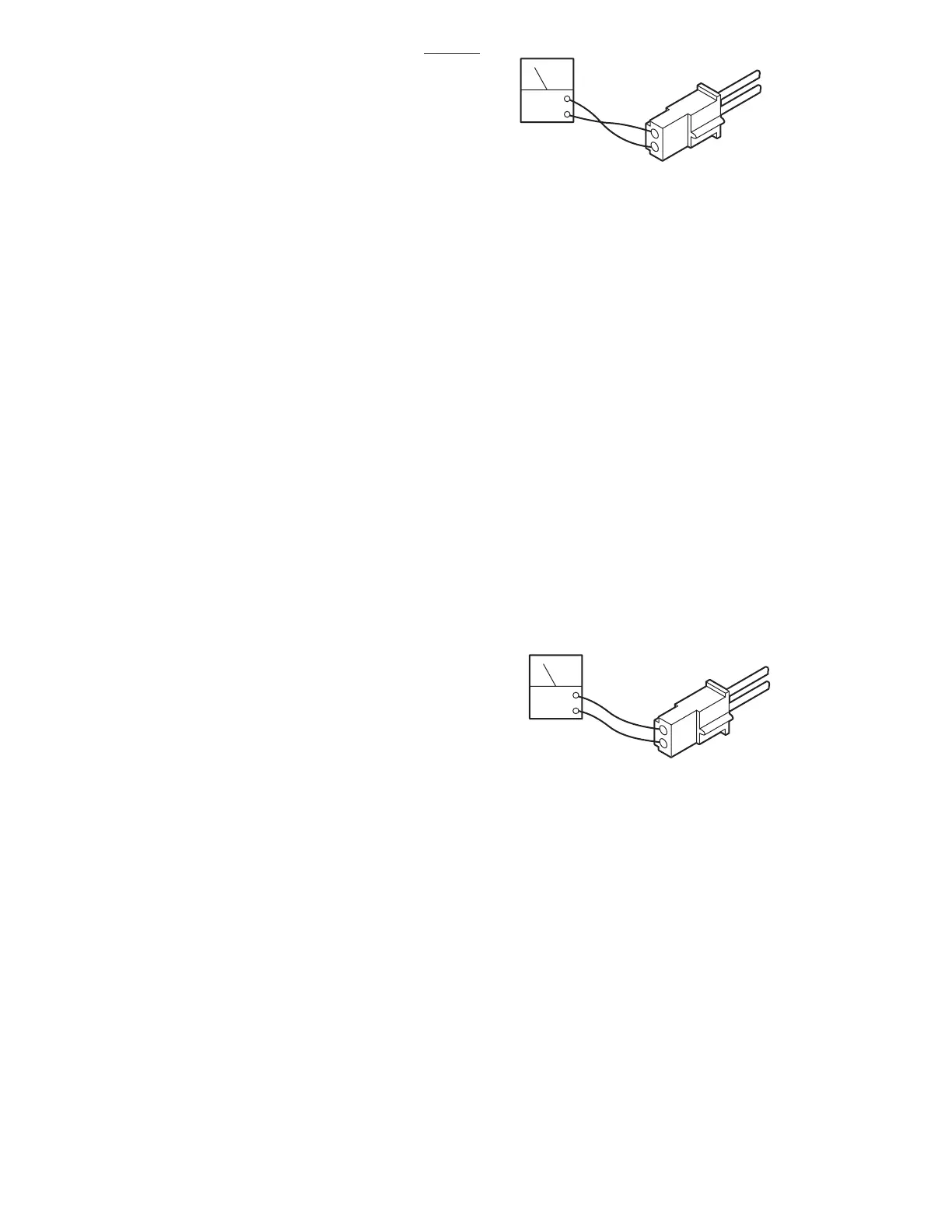

2. Activate any function and use a DC voltme-

ter to measure across the two pin connector. Pin

1(+) and pin 2(-). See figure 6-21. Meter should

read 24-28 volts.

Figure 6-21. Motor Input Voltage

Figure 6-22. Thermal Protector

DCV

CN15

2

1

DCV

2

1

CN16

3. The Thermal Relay should reset itself after

approximately one minute.

4. The Thermal Relay should activate after 1-

1/2 to 2 minutes of continuous pump operation.

c. Motor Resistance Test

The motor can be statically checked for resistance

using an ohmmeter. This test is not 100% accurate

because you are checking the motor with very low

voltage from the meter and without any load.

1. Using an ohmmeter R x 1 scale, measure the

resistance between the two pins of CN15. See

figure 6-22.

3500B

Loading...

Loading...